Multilevel rotational flow combined type air atomized fuel nozzle device and control method thereof

An air atomization and fuel nozzle technology, which is used in fuel injection devices, charging systems, engine components, etc., can solve the problems of few main combustion stage swirlers, weak functions, and single swirl organization, etc., to avoid The effect of local oil-rich area, reducing the average equivalence ratio, and avoiding smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

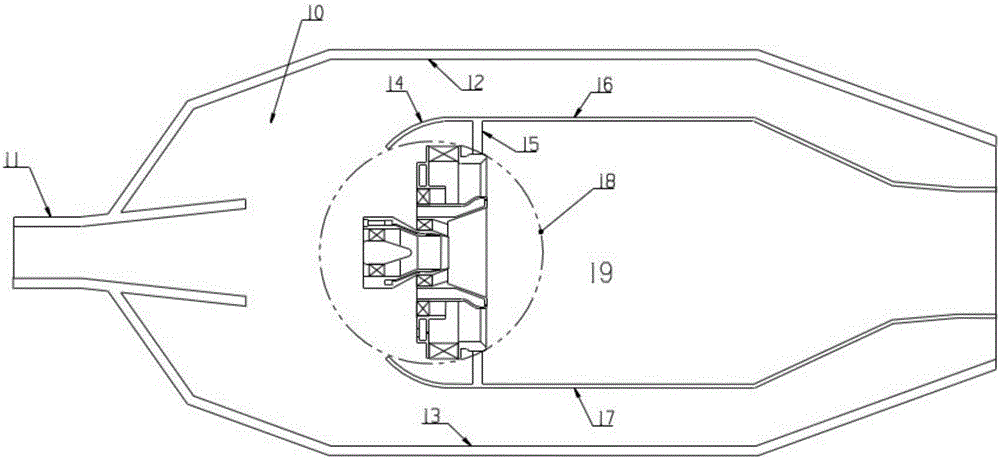

[0040] figure 1 It is a schematic diagram of a combustion chamber 10 with high temperature and increased oil-gas ratio. The combustion chamber is a straight-line single-ring cavity structure. , Outer flame tube 16, inner flame tube 17 and head swirler 18. The high-pressure air is decelerated and diffused by the diffuser 11 and divided into three routes. The first route of air passes through the head swirler 18 and mixes with the fuel, and then enters the combustion zone 19 to participate in combustion. The second and third routes of air flow through the outer casing 12 respectively. The two annular cavities between the outer flame tube 16 and the inner casing 13 and the inner flame tube 17 enter the cooling holes (not shown in the figure) provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com