Damping ring device used for controlling vibration of compressor blades

A technology for damping rings and compressors, applied in the field of damping rings, to achieve the effects of small additional mass, high reliability, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

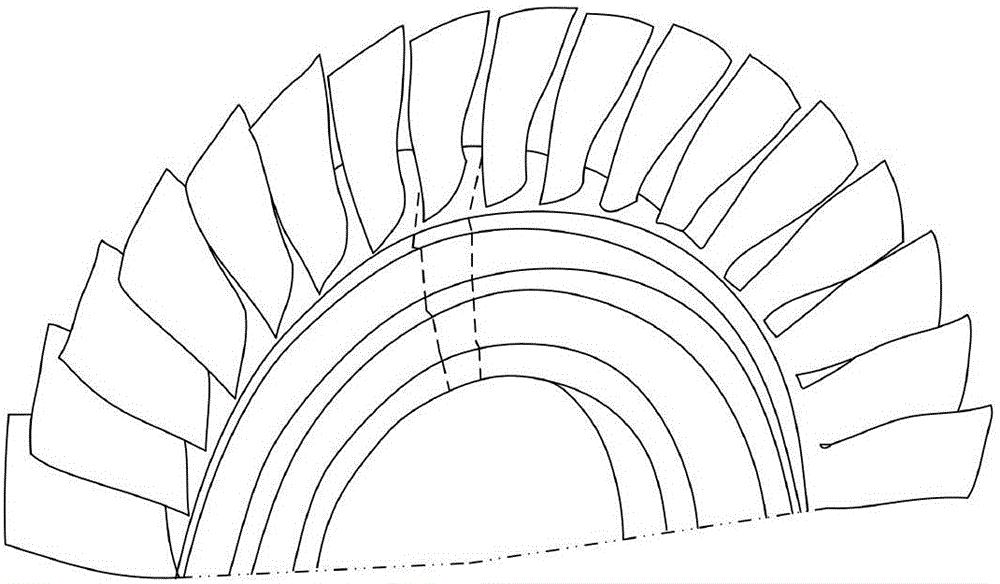

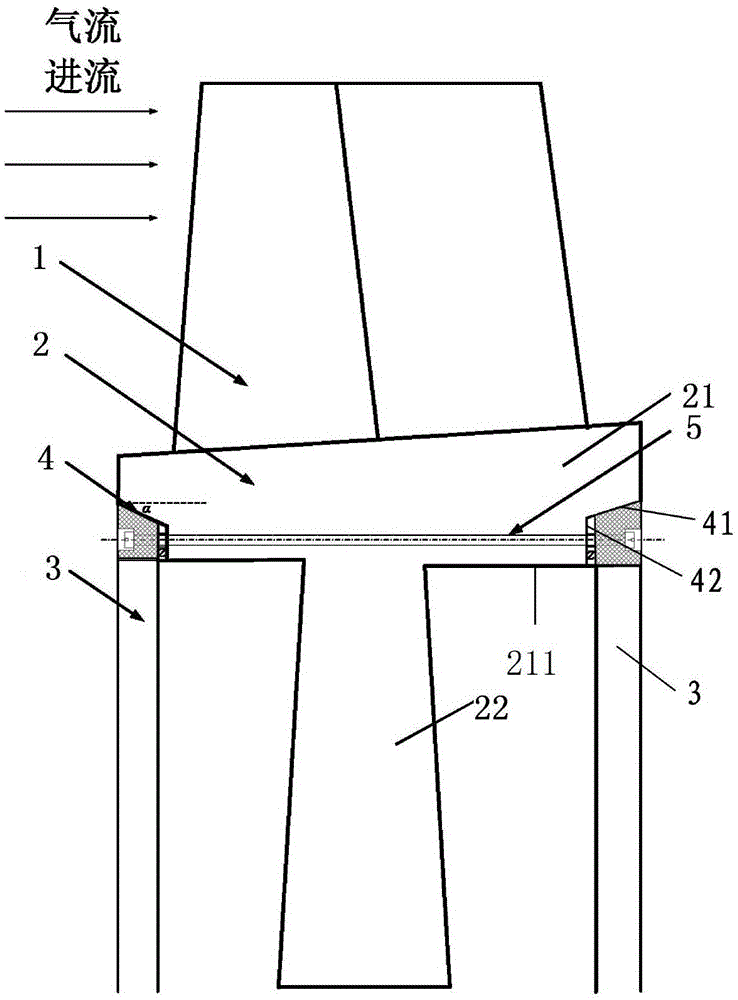

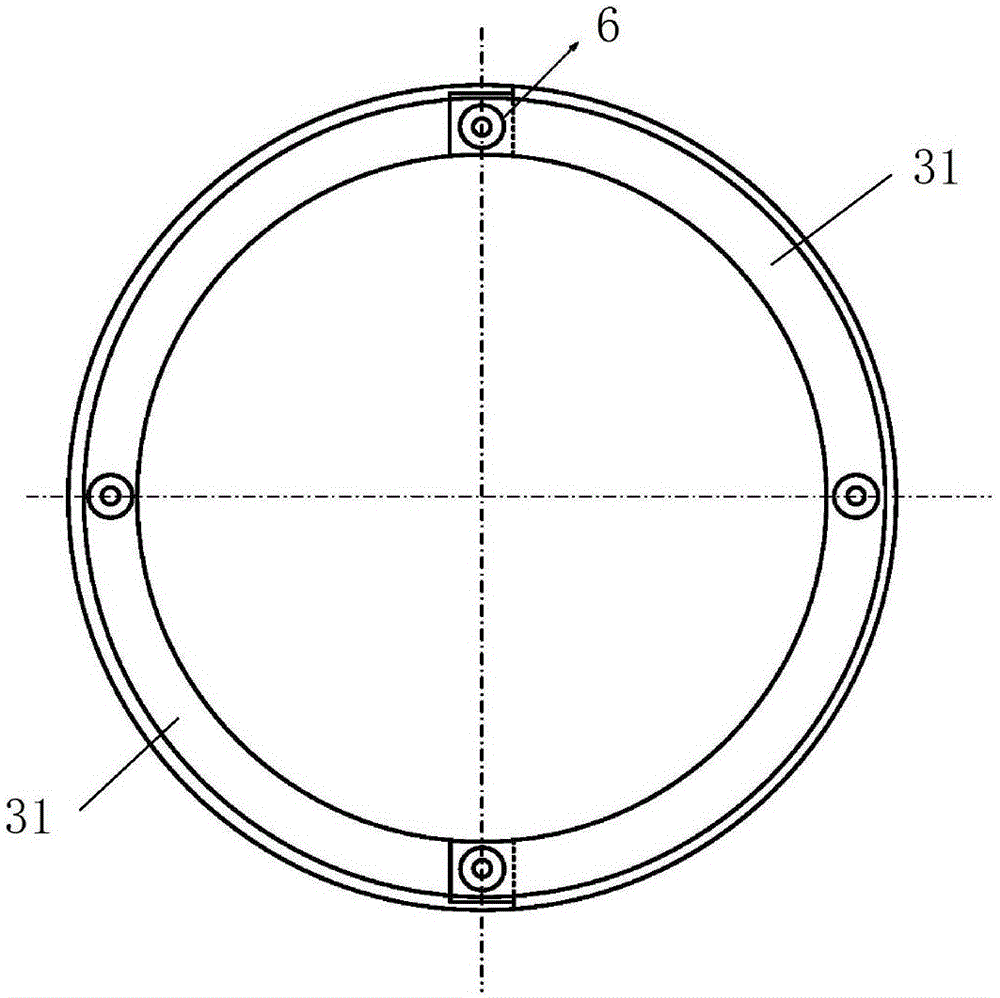

[0043] see figure 1 with 2 , with figure 1 A schematic diagram of the local structure of the compressor blisk of the present invention is disclosed, with figure 2 It is a structural schematic diagram of a single blade in the blisk connected to the damping ring by bolts. A damping ring device for controlling the vibration of compressor blades is provided, including a blade 1, a rim 2 and a damping ring 3, wherein the blade 1 is integrally formed with the rim 2 and is arranged on the rim 2 The outer side of the rim 2 includes a first structure part 21 and a second structure part 22, the second structure part 22 is arranged on the inner side of the first structure part 21, and the first structure part 21 has two A 7-shaped groove 4, the groove 4 is located on the inner side of the end surface of the upstream end of the first structure part 21 and the inner side of the end surface of the downstream end of the first structure part 21; The slot 4 is installed inside the first s...

Embodiment 2

[0052] see Figure 5 The difference between the second embodiment and the first embodiment is that the angle between the first groove surface 41 and the second groove surface 42 is a right angle. That is, when the contact surface between the damping ring 3 and the rim 2 is rectangular, no bolts are needed for connection, and the top of the damping ring 3 and the first groove surface 41 are interference fit, so that The damping ring 3 is locked in the first groove surface 41 .

[0053] During the process of the damping ring 3 being stuck on the first groove surface 41, the size of the damping ring 3 is reduced by using the principle of thermal expansion and contraction, and then it is stuck into the first groove surface 41, and the temperature is restored. When it reaches a normal value, the damping ring 3 and the first groove surface 41 of the rim 2 will be in an overstate due to thermal stress.

[0054] The present invention makes use of the pressure effect of the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com