Vibratory roller construction quality monitoring system based on Android platform

A vibratory roller, Android platform technology, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problems that the supervision cannot be checked in real time, the instrument is large in size, and the installation cost is high, so as to achieve rich man-machine interaction interface, Highly mobile, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The purpose of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

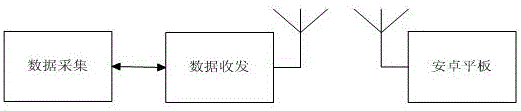

[0040] Such as figure 1 As shown, the Android platform-based vibratory roller construction quality monitoring system includes:

[0041] The data acquisition and sending and receiving module is used to wirelessly transmit the real-time rolling data obtained by processing and calculating the real-time collected vibratory roller rolling time, speed, trajectory, temperature, and vibration acceleration signals to the Android terminal;

[0042] The Android terminal is used to control and receive the real-time rolling data sent by the data acquisition and transceiver module, and display it in graphical form.

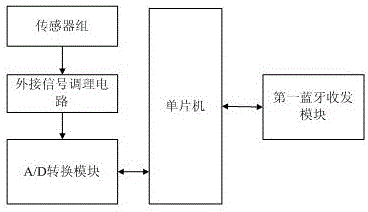

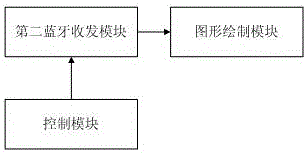

[0043] Such as figure 2 As shown, in one embodiment, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com