Embedded touch screen and display device

An embedded touch screen and substrate technology, applied in static indicators, instruments, electrical digital data processing and other directions, can solve the problems of high production cost and difficult process, and achieve the effect of reducing production cost and process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

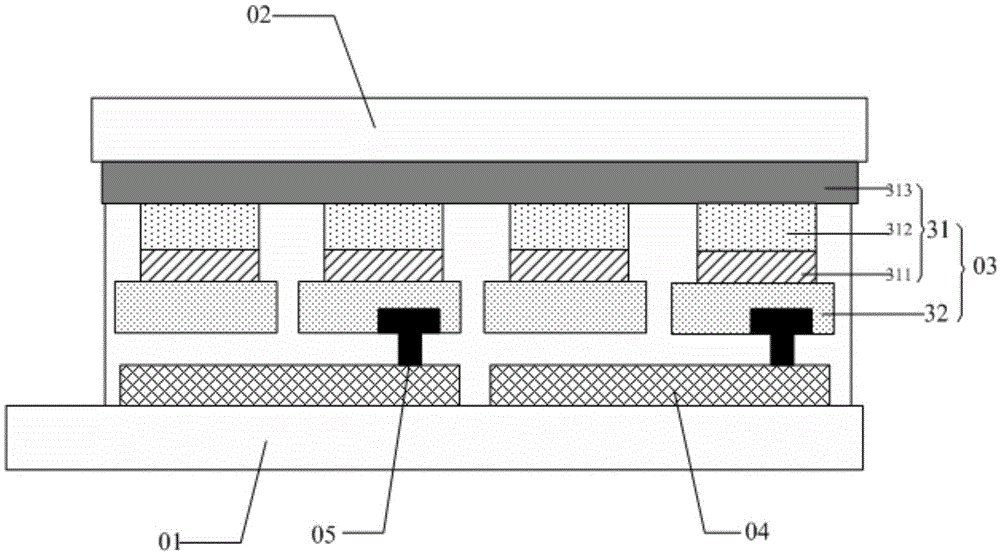

[0027] In the following, specific implementations of the in-cell touch screen and display device provided by the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

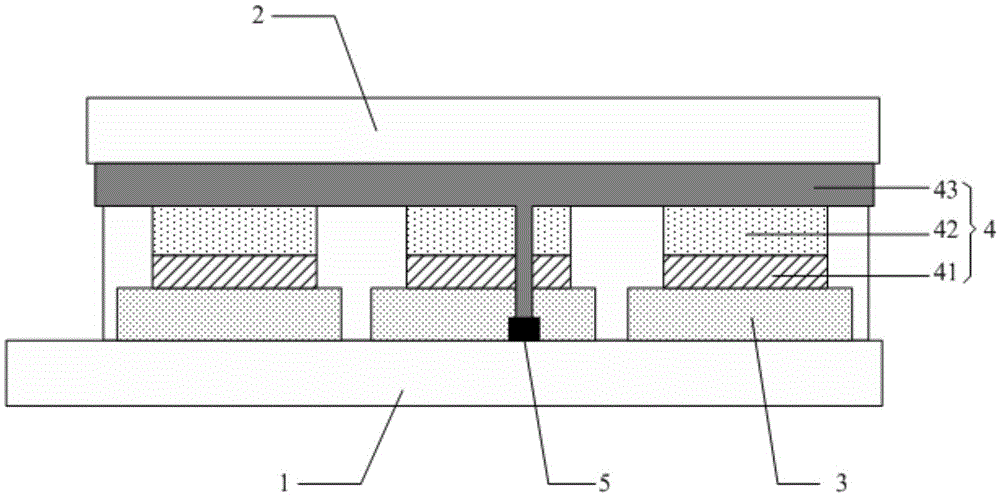

[0028] The thickness and shape of each film layer in the drawings do not reflect the true proportions of the in-cell touch screen, and are only intended to illustrate the content of the present invention.

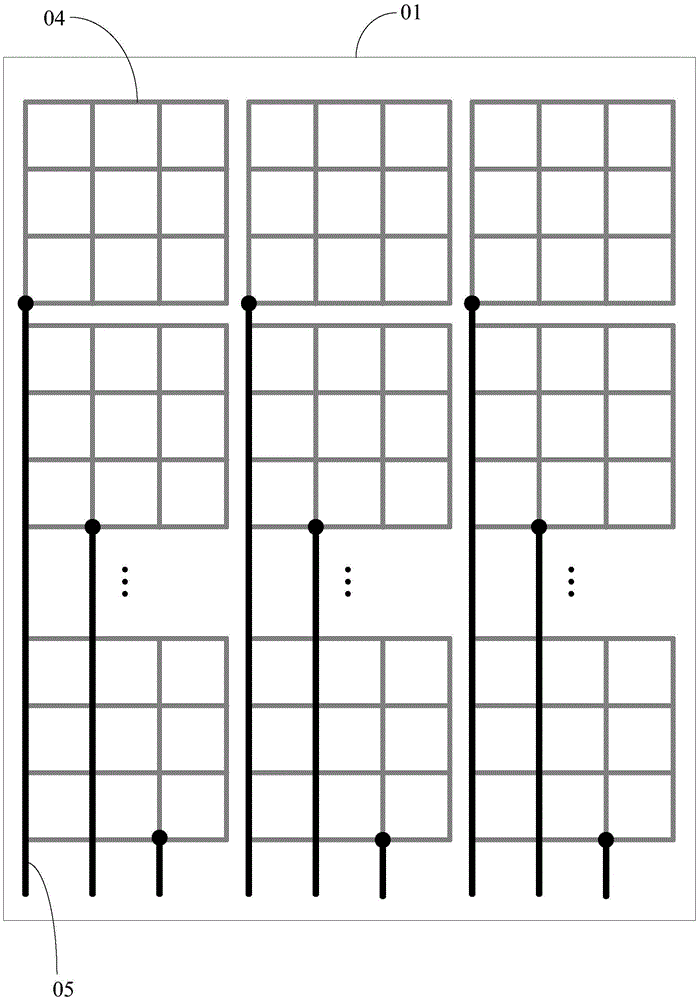

[0029] An embodiment of the present invention provides an in-cell touch screen, such as figure 2 As shown, it includes an upper substrate 02 and a lower substrate 01 arranged oppositely, and a number of pixel units 03 located on the side of the lower substrate 01 facing the upper substrate 02; wherein each pixel unit 03 includes a bottom emission type organic electroluminescence pixel structure 31 and a pixel circuit 32; The in-cell touch screen also includes:

[0030] A plurality of independent self-capacitance electrodes 04, which are located between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com