Automatic debugging method for cavity filter

A cavity filter and automatic debugging technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of high labor costs, time-consuming and laborious, and long education and training cycles, and achieve optimization of the assembly process, simple operation, and debugging. The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] like Figures 1 to 6 Shown, a kind of automatic debugging method of cavity filter, it comprises the following steps:

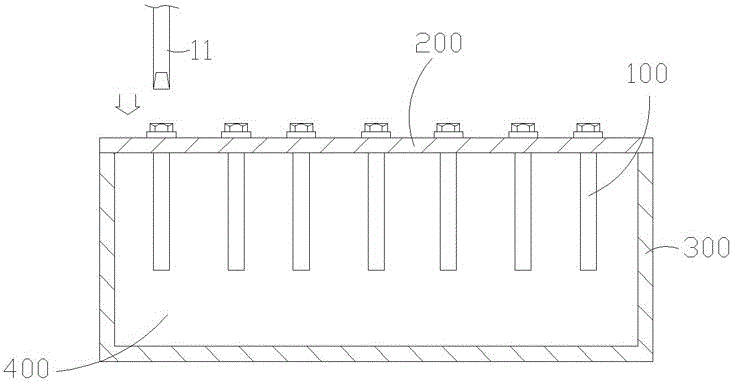

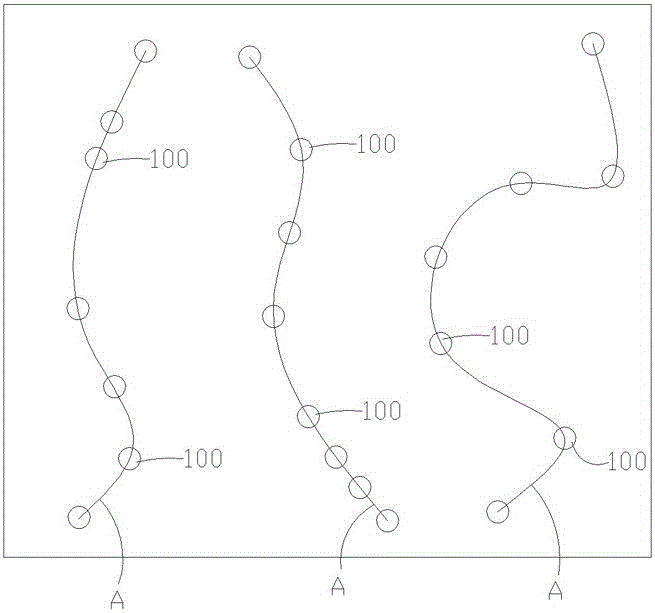

[0035] The first step is to fix several adjusting screws 100 on the cavity filter upper cover 200 , and then install the cavity filter upper cover 200 on the cavity filter box body 300 .

[0036] The cavity filter box 300 has an inner cavity 400 , and a plurality of adjusting screws 100 are extended in the inner cavity 400 to move up and down.

[0037]At this moment, the heights of the portions of the adjustment screws 100 extending in the inner cavity 400 are equal, and the heights enable the bandwidth data of each frequency band to appear.

[0038] The cavity filter changes its inductance and capacitance by changing the height at which the adjustment screw 100 protrudes into the resonant cavity in the cavity 400 .

[0039] During specific implementation, the cavity filter upper cover 200 is mounted on the cavity filter box body 300 using a contour t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com