A method for preparing trichlorosilane

A technology of trichlorosilane and silicon tetrachloride, applied in chemical instruments and methods, silicon compounds, metal silicides, etc., can solve the problems of small promotion effect and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

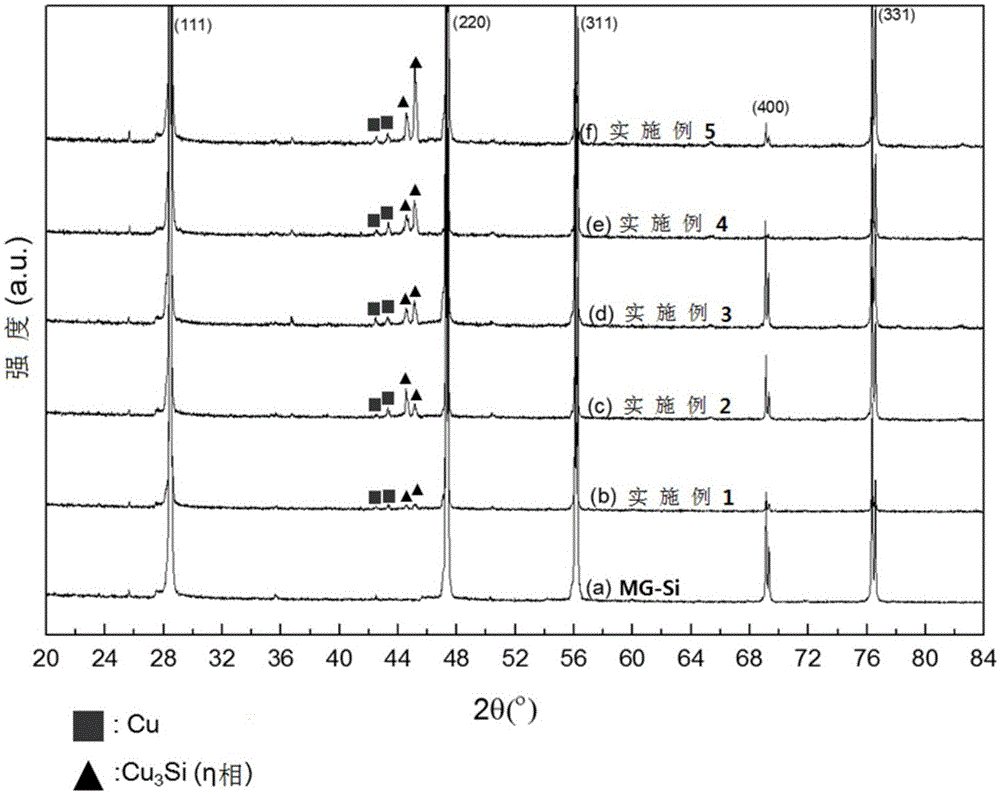

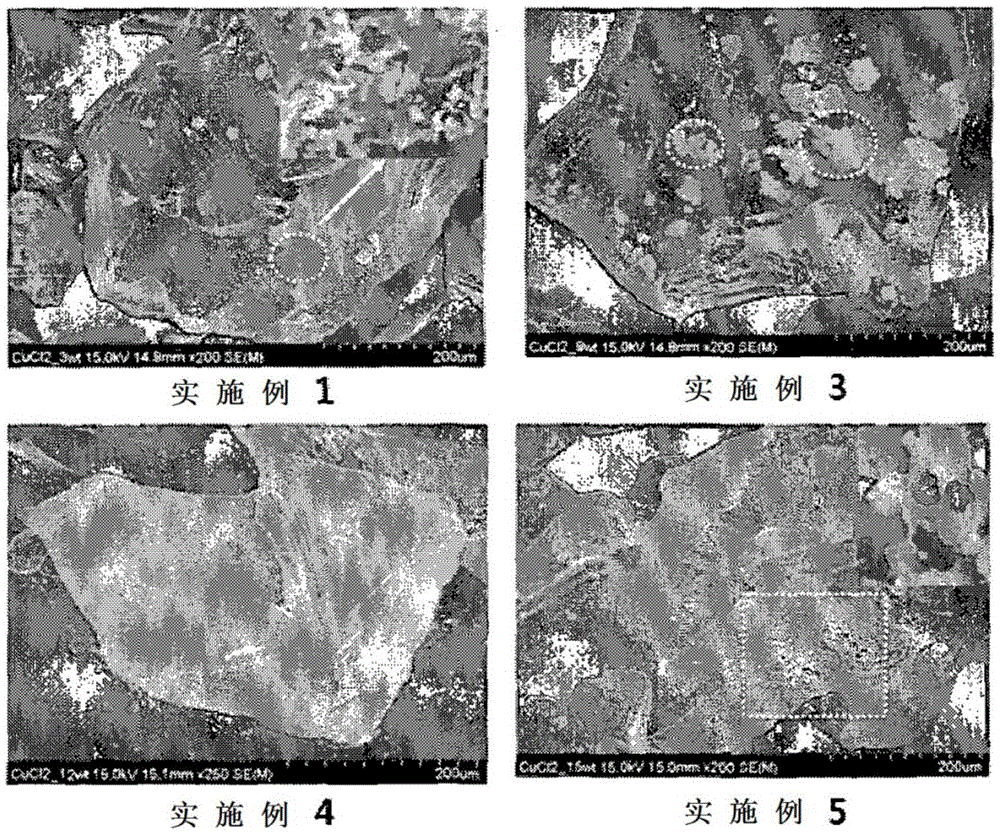

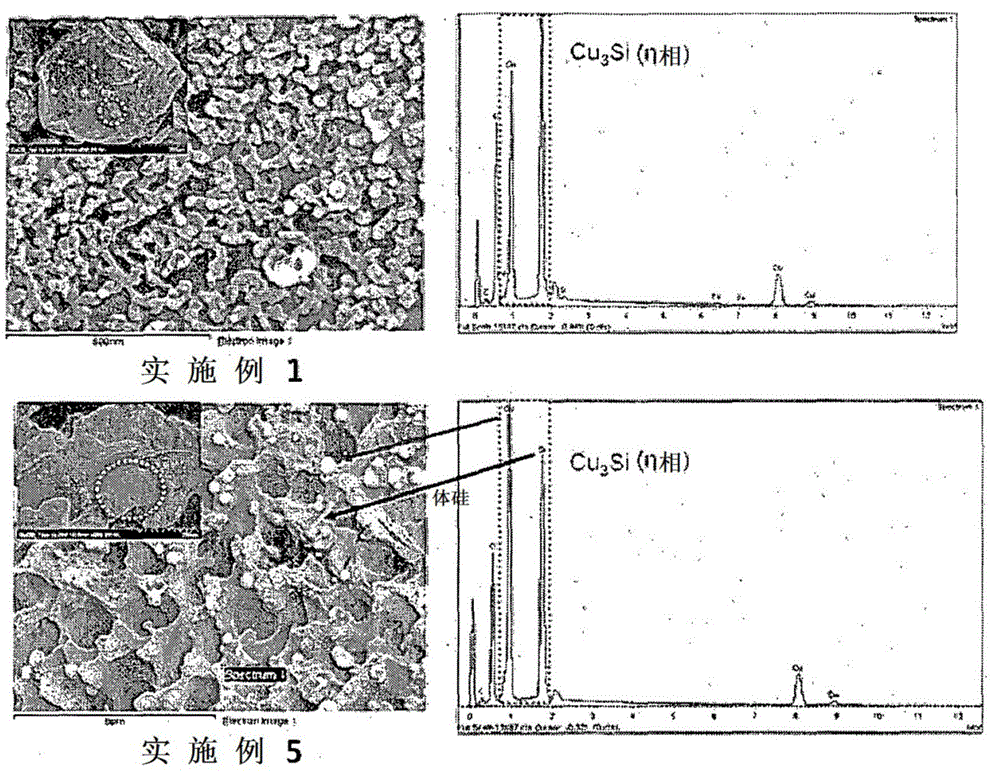

[0020] The method for preparing trichlorosilane of the present invention includes: heat-treating silicon (Si) and copper (Cu) compounds to a temperature equal to or higher than the melting point of the copper compound to form copper silicide (Cu-silicide) on the silicon. ); and supplying silicon tetrachloride and hydrogen to the Cu-silicide-formed silicon for hydrochlorination.

[0021] As a method for producing trichlorosilane, direct chlorination and hydrochlorination (HC) are commercially used.

[0022] The hydrochlorination reaction is to make silicon with silicon tetrachloride (STC) and hydrogen (H 2 ) reaction to prepare the process of trichlorosilane, the overall reaction is shown in the following formula 1.

[0023] [Formula 1]

[0024] 3SiCl 4 +2H 2 +MG-Si→4SiHCl 3

[0025] The overall reaction of described formula 1 can be divided into two-step reaction as shown below:

[0026] [Formula 2]

[0027] SiCl 4 +H 2 →SiHCl 3 +HCl

[0028] [Formula 3]

[0029] ...

Embodiment 1

[0057] 170 g of MG-Si with a purity of more than 99% and an average particle size of 250 μm were mixed with a content of 1.4 wt% of MG-Si (based on CuCl 2 weight of Cu in CuCl 2 Mixing, the temperature was raised to 700° C. at a rate of 4° C. / min in a mixed gas environment containing hydrogen and nitrogen at a weight ratio of 1:9. The mixture was kept at 700°C for 1 hour, and then cooled to room temperature to obtain MG-Si in which Cu-silicide was formed.

[0058] In a fixed-bed reactor, 170 g of MG-Si formed with Cu-silicide was filled, and then, at a temperature of 525 °C and a pressure of 20 bar, the 2 :SiCl 4 =2:1 molar ratio to carry out the hydrochlorination reaction for 2 to 10 hours to prepare trichlorosilane.

Embodiment 2

[0060] Except that in Example 1 the mixing content is 2.7wt% of MG-Si (based on CuCl 2 weight of Cu in CuCl 2 Except that, trichlorosilane was prepared by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com