A kind of composite material and its preparation method and application

A technology of composite materials and mixed materials, which is applied in applications, other household appliances, ceramic products, etc., can solve the problems of increasing interface thermal resistance, which cannot be further improved, and the thermal conductivity of CuSiC is low, so as to achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present disclosure provides a preparation method of a composite material, the method comprising: preparing a carbon-coated silicon carbide skeleton; filling copper or a copper alloy into the pores of the carbon-coated silicon carbide skeleton.

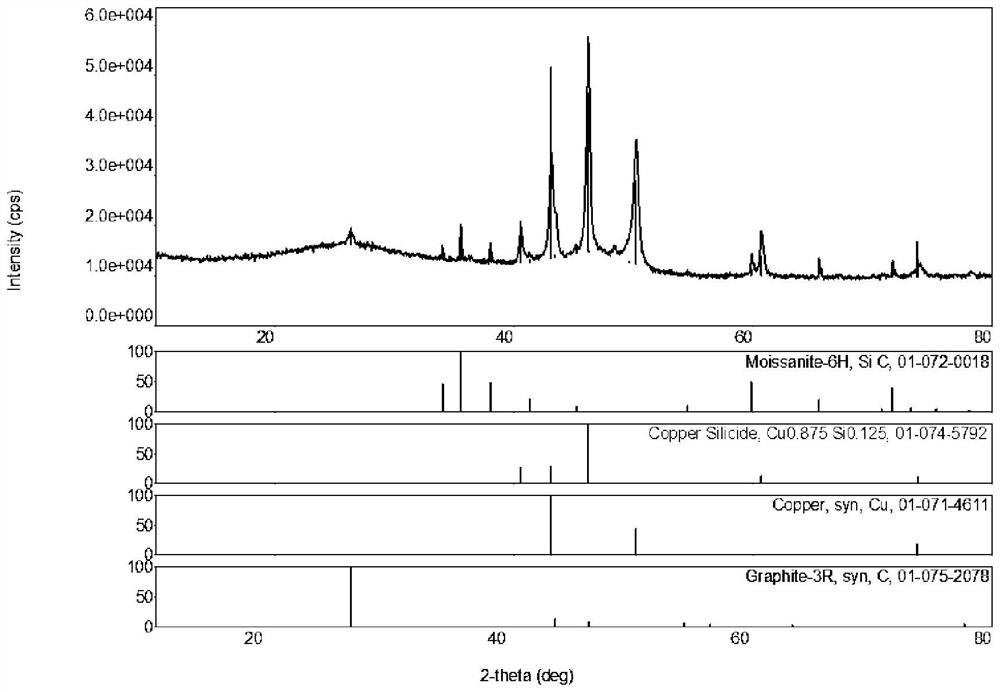

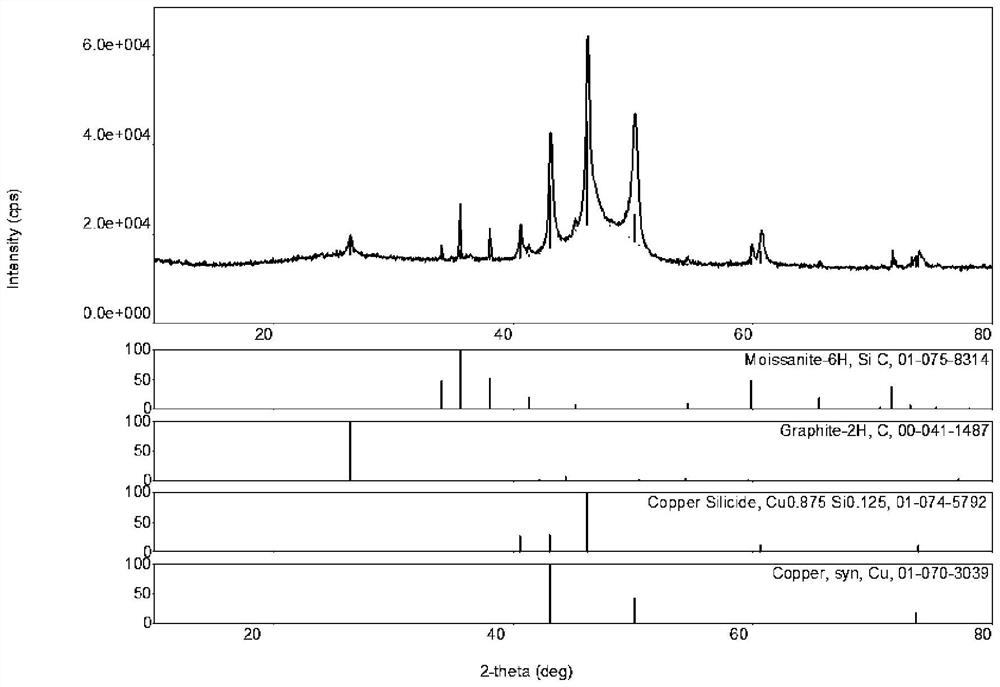

[0035] According to the present disclosure, carbon is used to coat the surface of the silicon carbide skeleton (the surface refers to the surface of the silicon carbide skeleton in contact with the air, including both the outer surface of the skeleton and the surface of the internal pores of the skeleton), so as to reduce the contact between silicon carbide and copper or copper alloy. reaction, thereby reducing the generation of copper silicide and improving the thermal conductivity of the composite material. The silicon carbide skeleton is well known to those skilled in the art, and refers to a three-dimensional porous structure formed by sintering silicon carbide particles at high temperature. The carbon coated on the surf...

Embodiment 1

[0047] 100 parts of silicon carbide particles (particle size 20-100 microns), 10 parts of graphite powder (particle size 0.1 microns), 22.5 parts of phenolic resin (liquid) ethanol dispersion (containing 15 parts of phenolic resin, phenolic resin carbon content 45% by weight) and 1 part of polyvinyl alcohol were mixed in a tank mixer for 2 hours to obtain a mixed material.

[0048] The obtained mixed material is granulated in a granulator and passed through a 60-mesh sieve to obtain a powder; the obtained powder is compacted with a compacting machine, the compacting pressure is 15MPa, and the pressure is maintained for 40s to obtain a blank; the obtained blank is Parts were solidified in an oven at 200°C for 30 minutes to obtain a shaped blank; the resulting shaped blank was pyrolyzed in a vacuum atmosphere furnace for 180 minutes under a vacuum condition of 800°C (vacuum degree below 10Pa) to obtain a carbon Coated silicon carbide skeleton.

[0049] Put the obtained carbon-c...

Embodiment 2

[0051] The preparation steps are basically the same as in Example 1, except that graphite powder is used to replace the same weight of phenolic resin to obtain composite material-2. The specific composition and thermal conductivity are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com