Copper microalloy, copper microalloy wire and preparation methods of copper microalloy and copper microalloy wire

A technology of micro-alloy and copper alloy, which is applied in the direction of metal/alloy conductor, cable/conductor manufacturing, conductor, etc., can solve the problems of poor electric thermal fatigue resistance, lower application reliability, potential difference corrosion, etc., and achieve improved heat resistance Poor fatigue resistance, improved tensile strength, and improved fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The copper microalloy in this example contains by weight: palladium 0.7%, gold 0.5%, silver 0.3%, platinum 0.2%, phosphorus 0.05%, silicon 0.05%, and the balance is copper. In this copper microalloy, phosphorus is represented by copper phosphide (Cu 3 P 2 ) in the form of silicon as copper silicide (Cu 5 Si) exist in the form.

[0045] The preparation method of above-mentioned copper microalloy comprises the following steps:

[0046] (1) Equipped with the following raw materials: copper, palladium, gold, silver, platinum, phosphorous copper master alloy material (the equipped phosphorous copper master alloy material is a homogenized phosphorous copper master alloy material, containing 5wt.% phosphorus and 95wt .% copper) and copper-silicon master alloy material (the equipped copper-silicon master alloy material is a homogenized copper-silicon master alloy material, containing 2 wt.% silicon and 98 wt.% copper);

[0047] All raw materials generally contain the followin...

experiment example

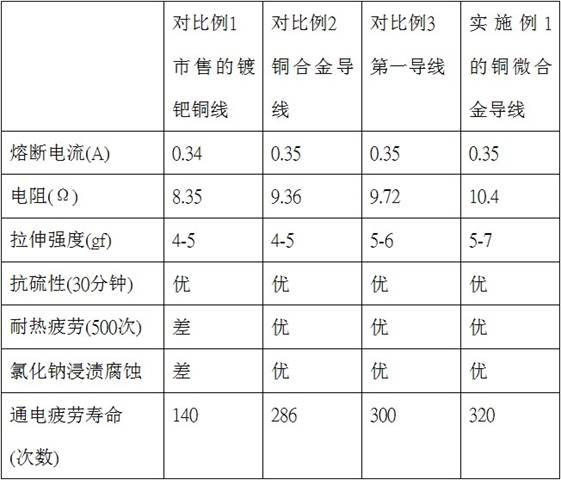

[0075] Take commercially available palladium-plated copper wire (Comparative Example 1), the copper alloy wire prepared in Comparative Example 2, the first wire prepared in Comparative Example 3, and the copper microalloy wire prepared in Example 1, and test the fusing current, Electrical resistance, tensile strength (many tests were performed, and the numerical range was counted), sulfur resistance, thermal fatigue, sodium chloride immersion corrosion resistance, and electrification fatigue life. The diameter of each wire used above was all 18 μm.

[0076] Measurement methods:

[0077] The measurement of sulfur resistance is to place the object to be tested in sulfur vapor at 120°C and bake for 1 hour, and observe the color change of the line surface after baking. If it turns yellow or black, it means poor vulcanization resistance; if there is no obvious discoloration, it means excellent vulcanization resistance.

[0078] The measurement of thermal fatigue is to heat the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com