High-strength steel wire material exhibiting excellent cold-drawing properties, and high-strength steel wire

A high-strength steel wire, high-strength technology, applied in the direction of metal material coating process, coating, furnace type, etc., can solve the problem of low wire drawing processability, and achieve the effect of excellent raw drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

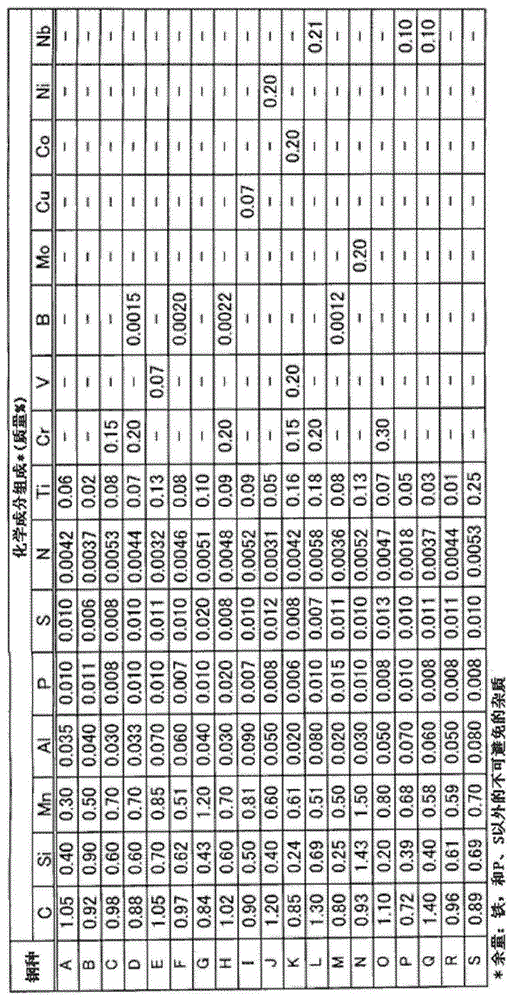

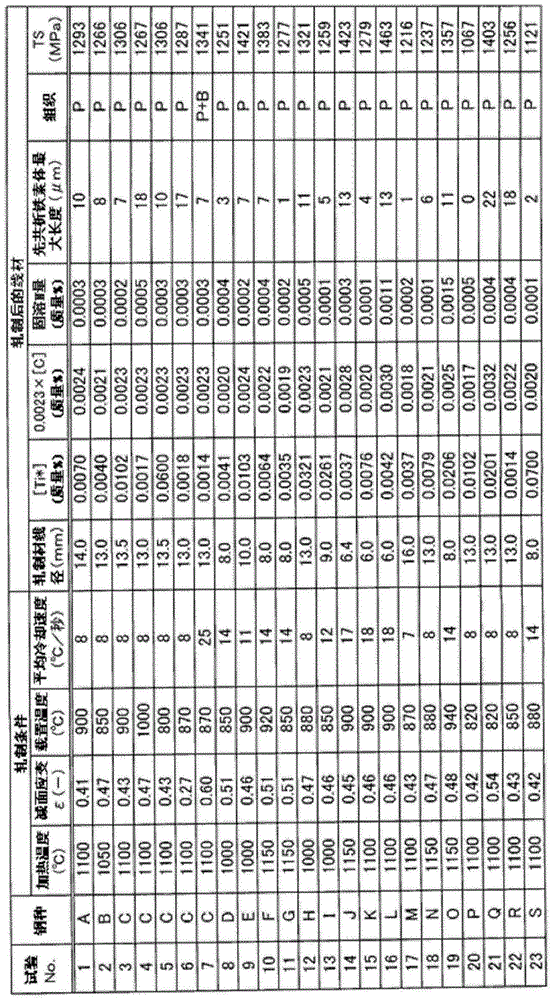

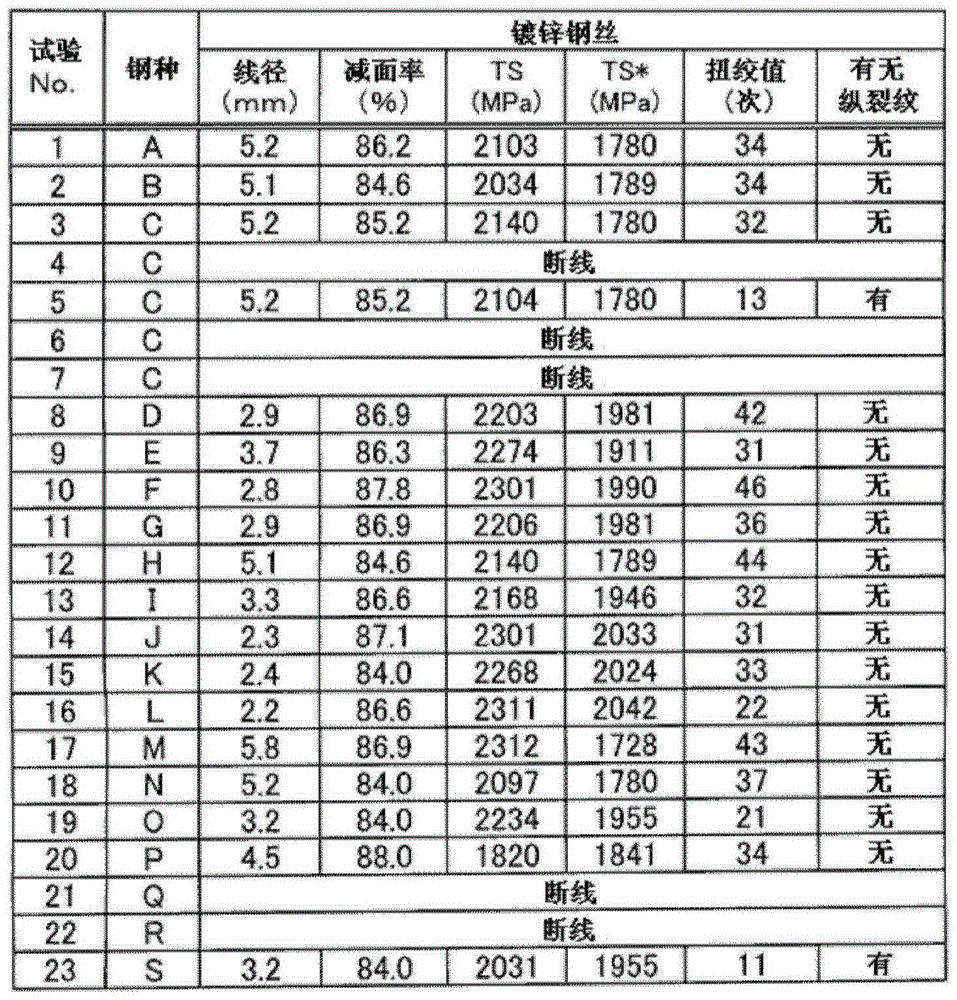

Examples

Embodiment Construction

[0028] In order to solve the above-mentioned problems, the inventors of the present invention studied the relationship between the structure of the wire rod and the wire drawability. In particular, the precipitation mechanism of proeutectoid cementite in hypereutectoid steel has also been studied. As a result, it was found that precipitation of pro-eutectoid cementite can be suppressed by precipitating fine TiC in the vicinity of grain boundaries. The effect is greatest for fine TiC having a size of 0.1 μm or less, and it is necessary to ensure a sufficient amount of precipitation of fine TiC. The higher the C content of the steel, the easier it is to precipitate cementite, so more fine TiC is needed. Since it is difficult for coarse TiC to exhibit such an effect, it is necessary to precipitate as much fine TiC as possible. It is extremely important to properly control the precipitation amount and size distribution of TiC.

[0029] Precipitating fine TiC having a size of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com