Grillage machine provided with cake-shaped filter bodies

A round cake-shaped, grid machine technology, applied in the field of grid machines, can solve the problems of high maintenance cost, easy damage to chains and sprockets, low decontamination efficiency, etc., and achieves small footprint, convenient maintenance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

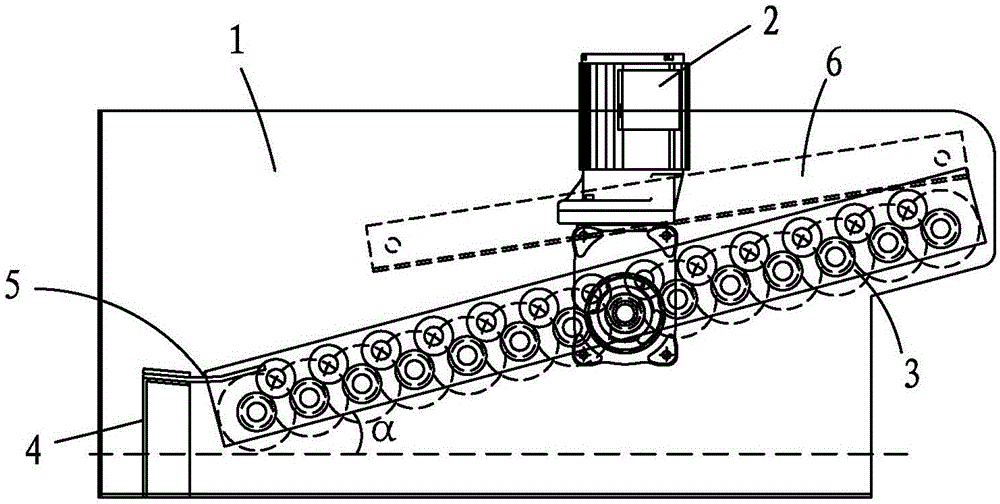

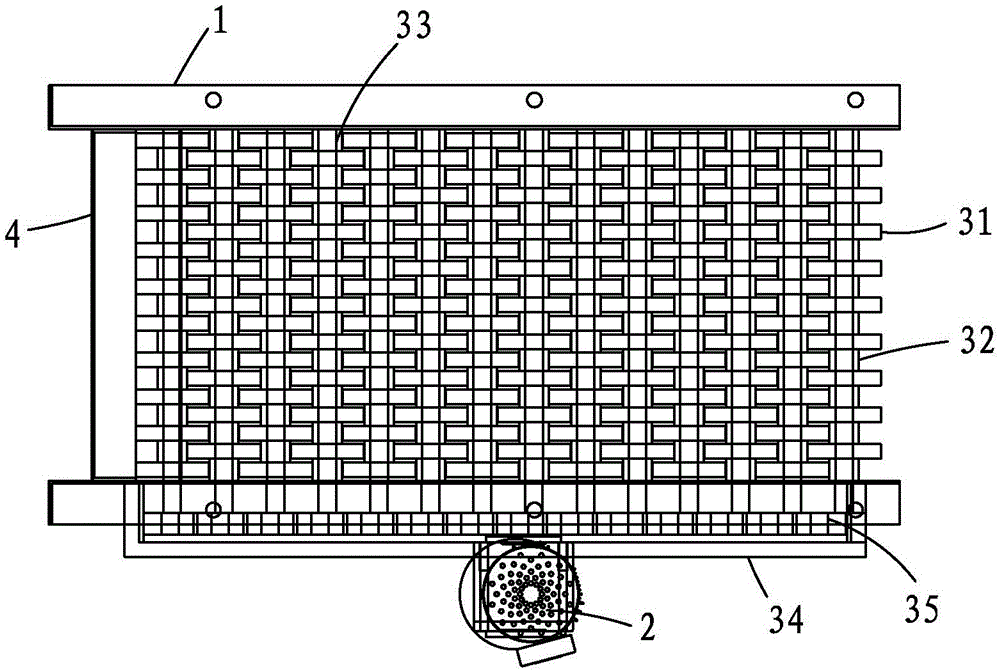

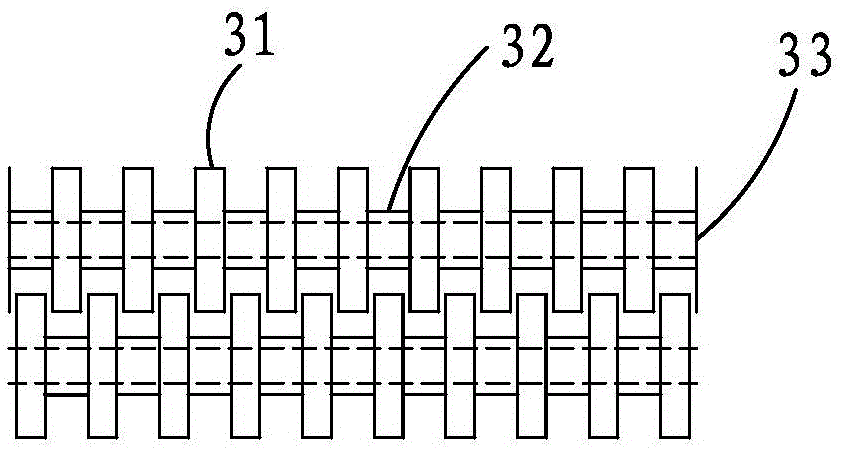

[0017] see Figure 1 to Figure 3 , a grid machine with a circular cake-shaped filter body, including two symmetrically distributed side plates 1, a drive motor 2, and a filter device 3; the filter device 3 includes a plurality of circular cake-shaped filter bodies 31, a plurality of Gasket 32 and a plurality of pillars 33; the pillars 33 are fixed between the two side plates 1; the circular cake-shaped filter body 31 and the gasket 32 are alternately arranged in series on the same pillar 33, and two adjacent pillars 33 The circular cake-shaped filter body 31 and gasket 32 on the top are also alternately arranged; the end of each pillar 33 is sleeved with a transmission gear 34, and two adjacent gears 34 mesh with each other to form a gear transmission group 35. The gear transmission group 35 is driven by the drive motor 2, thereby driving the pillar 33 to rotate; the filter device 3 is arranged obliquely, forming an inclination angle α with the horizontal plane, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap