Preparation method of IL, magnetic graphene oxide nano-material and application of magnetic graphene oxide nano-material

A nanomaterial and graphene technology, applied in the field of plant growth regulators, can solve the problems of low accuracy, sensitivity and precision of analytical methods, and the inability to achieve selective adsorption of various plant growth regulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

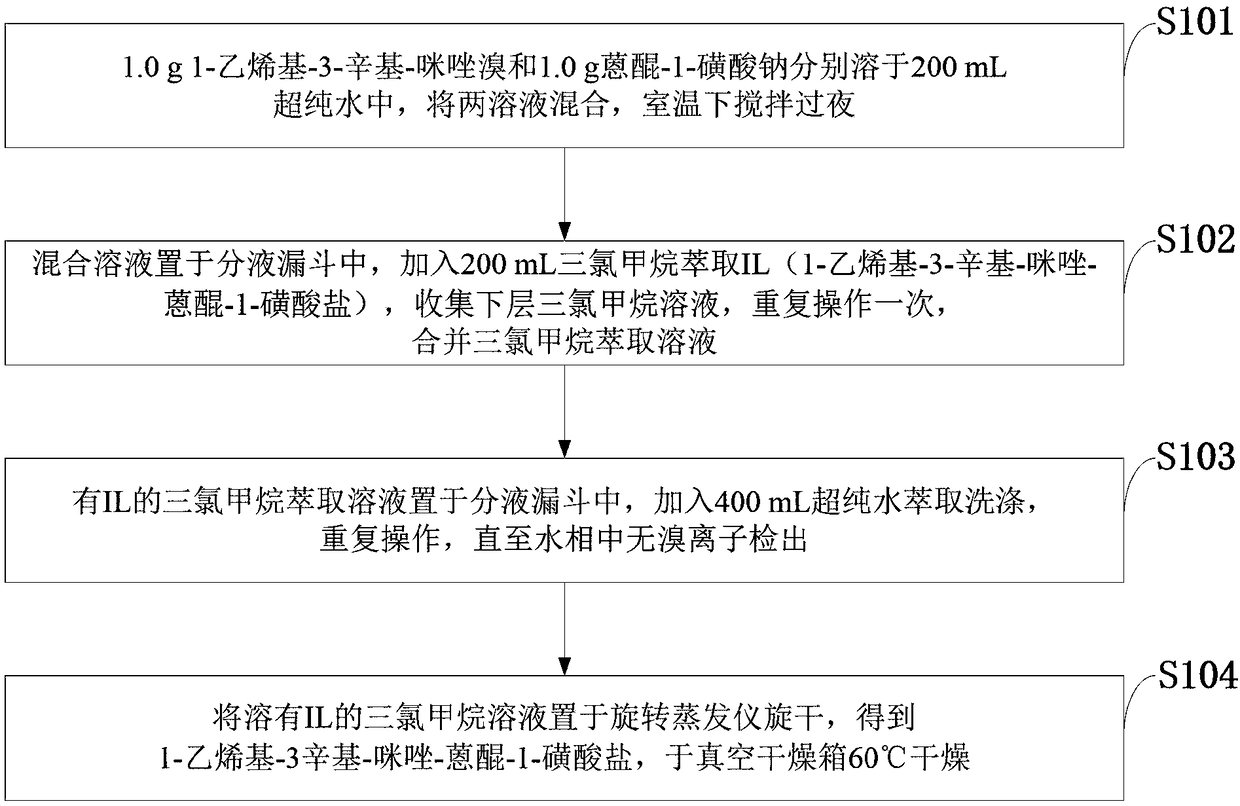

[0069] Such as figure 1 As shown, the preparation method of the ionic liquid 1-vinyl-3-octylimidazole-anthraquinone-1-sulfonate (IL) provided by the embodiment of the present invention comprises the following steps:

[0070] S101: Dissolve 1.0g of 1-vinyl-3-octyl-imidazolium bromide and 1.0g of sodium anthraquinone-1-sulfonate in 200mL of ultrapure water, mix the two solutions, and stir overnight at room temperature;

[0071] S102: Put the mixed solution in a separatory funnel, add 200 mL of chloroform to extract IL (1-vinyl-3-octyl-imidazole-anthraquinone-1-sulfonate), collect the lower layer of chloroform solution, and repeat the operation Once, combine the chloroform extraction solution;

[0072] S103: Place 1 L of chloroform extraction solution in a separatory funnel, add 400 mL of ultrapure water for extraction and washing, and repeat the operation until no bromide ions are detected in the water phase;

[0073] S104: Put the IL-dissolved chloroform solution in a rotary...

Embodiment 1

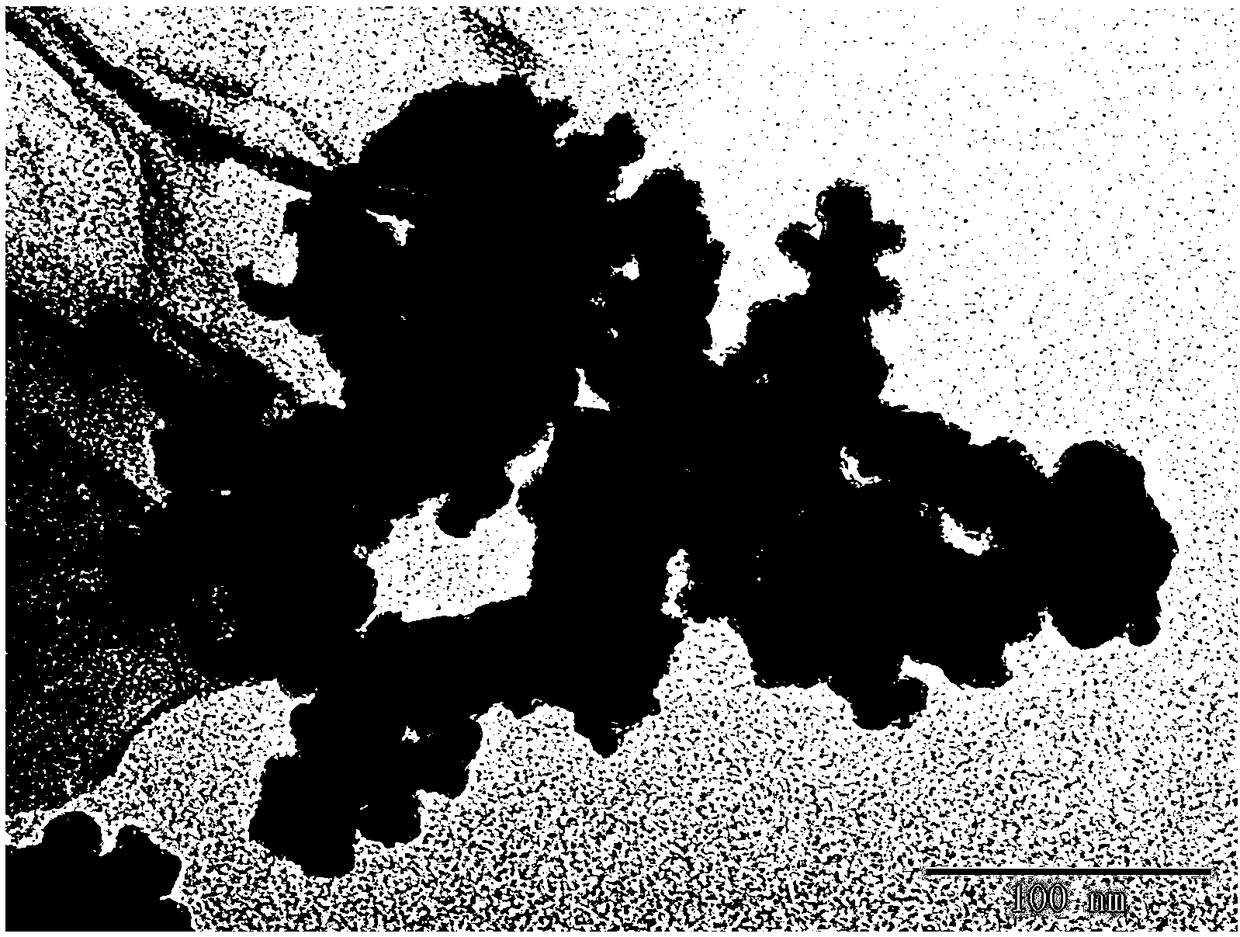

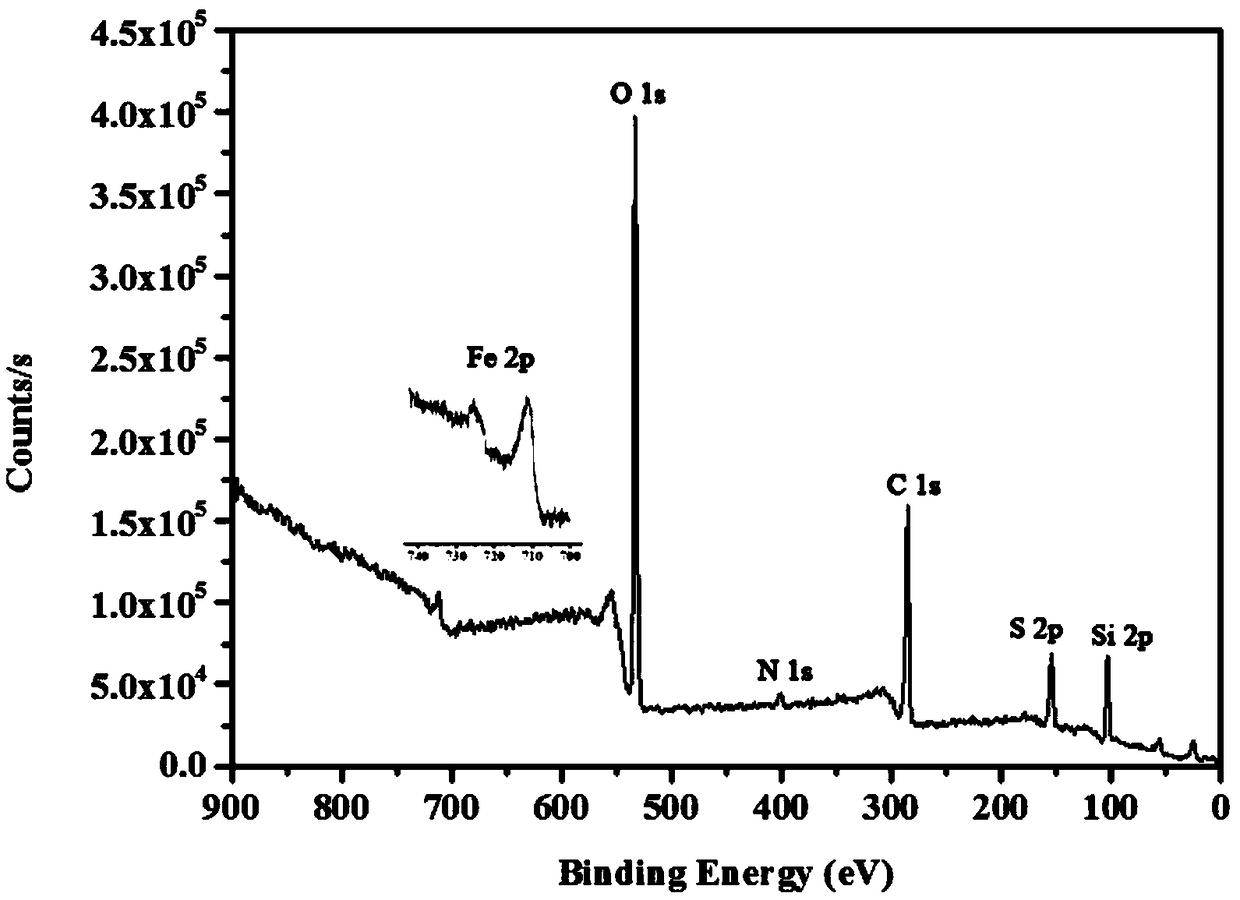

[0105] (1) Preparation of magnetic Fe 3 o 4 @SiO 2 nanomaterials

[0106] Add 3.40g of ammonium ferrous sulfate hexahydrate and 8.35g of ammonium ferrous sulfate dodecahydrate into 300mL of ultrapure water at 50°C under nitrogen protection, add 20mL of 8mol / L ammonia water dropwise, and sonicate for 10min. The mixture was adjusted to pH 11-12 with NaOH, stirred at 1200 r / min at 50°C for 2 h, and the black precipitate was separated by an external magnetic field and washed with water until neutral. The precipitate was dispersed in 20mL ultrapure water, 1.7mL polyvinylpyrrolidone was added, and stirred at room temperature for 24h, the obtained Fe 3 o 4 The nanomaterials were washed three times with water and ethanol, respectively, and dried in vacuum. 1.4g Fe 3 o 4 Disperse in a mixed solution containing 280mL ethanol, 70mL ultrapure water, and 5mL ammonia water, stir at 30°C for 15min, add 4mL ethyl orthosilicate dropwise, and stir at room temperature for 8h. Product Fe ...

Embodiment 2

[0116] Each process step is according to embodiment 1, only the IL consumption in the step (5) is changed into 0.4g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com