Self pressure release single mode microwave reaction system

A single-mode microwave and reaction system technology, which is applied in the field of chemical analysis instruments, can solve problems such as loss of pressure bearing function, high microwave field strength, and bursting of digestion filling, so as to reduce the risk of bursting, reduce operation and use costs, and reduce work The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the drawings.

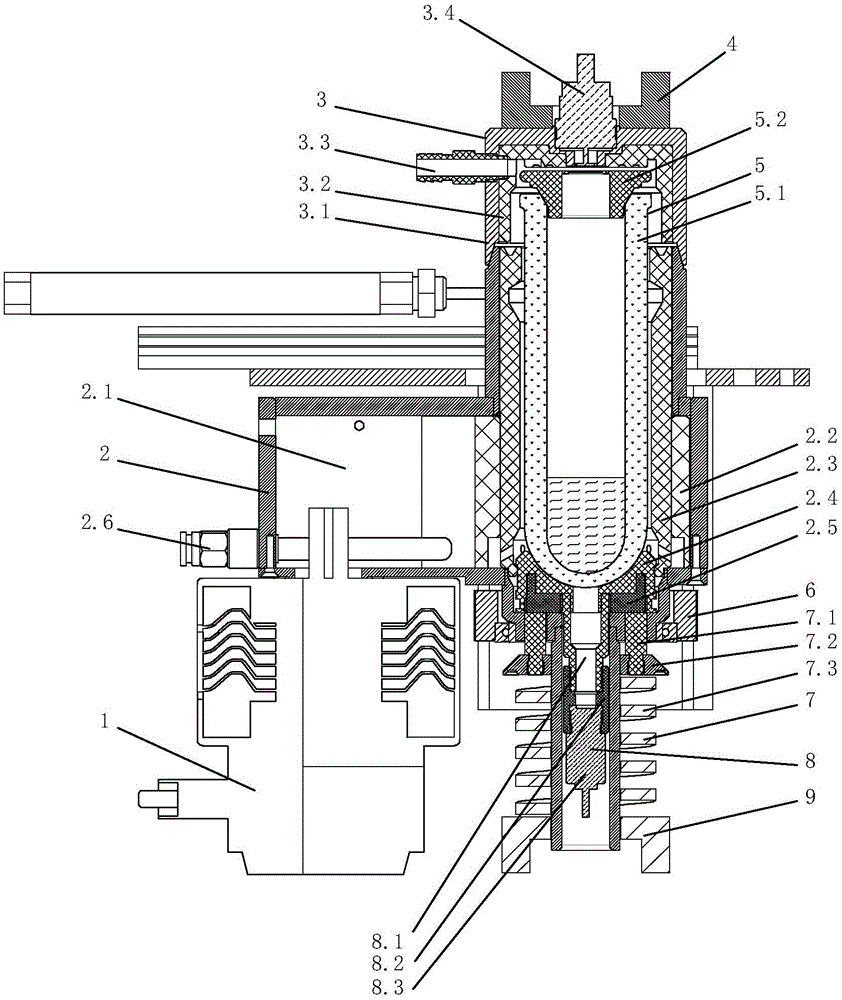

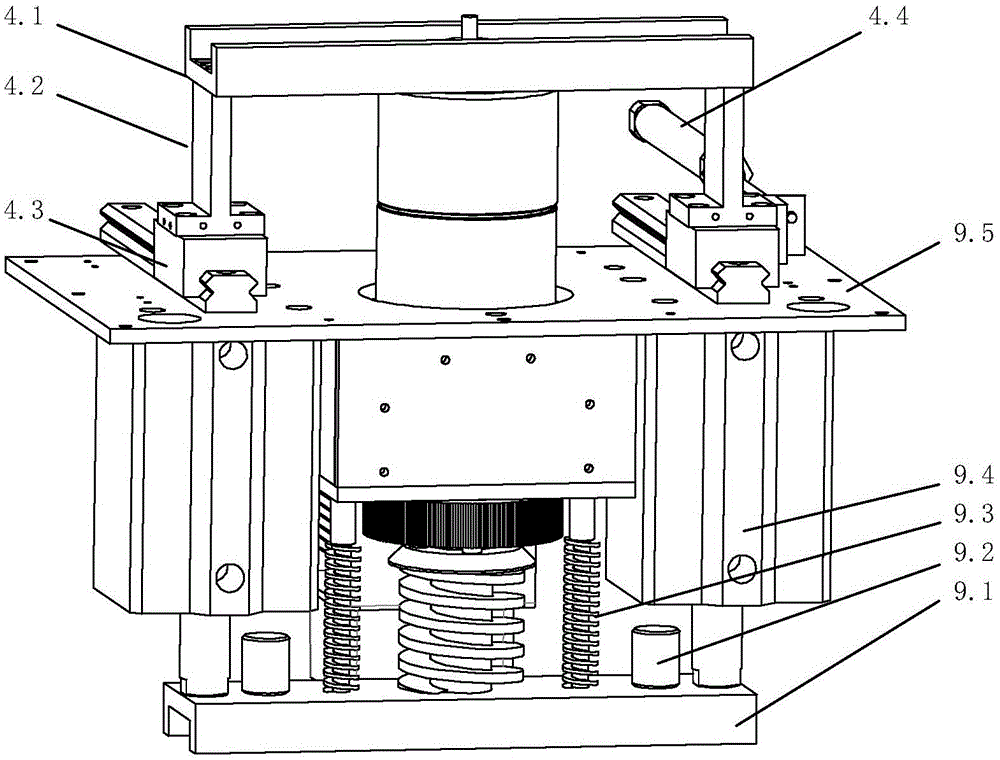

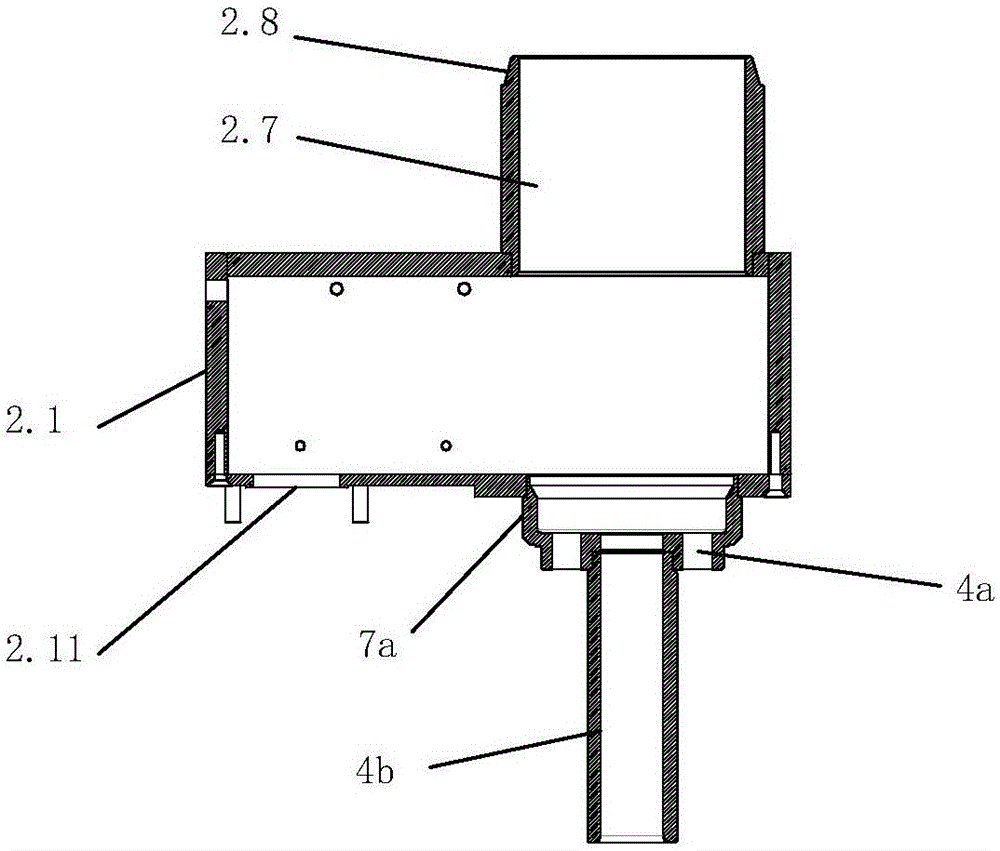

[0073] figure 1 with figure 2 Among them, the technical solution of the present invention provides a self-relief single-mode microwave reaction system, and its invention lies in:

[0074] The self-relief single-mode microwave reaction system consists of a magnetron 1, a single-mode cavity component 2, a single-mode sealing cover component 3, a sealing cover sliding component 4, a test tube component 5, a magnetic stirring component 6, an automatic pressure relief component 7. Infrared temperature measuring component 8 and single-mode cavity lifting component 9 are composed;

[0075] Wherein, in the single mold cavity assembly, a test tube assembly is provided; the test tube assembly includes at least test tube 5.1;

[0076] Above the test tube assembly, a single mold sealing cover assembly and a sealing cover sliding assembly are provided;

[0077] Below the test tube assembly, a magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com