Portable bearing hydraulic assembly and disassembly device

A bearing, assembly and disassembly technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high noise, damage to bearing accuracy, shorten working life, etc., and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

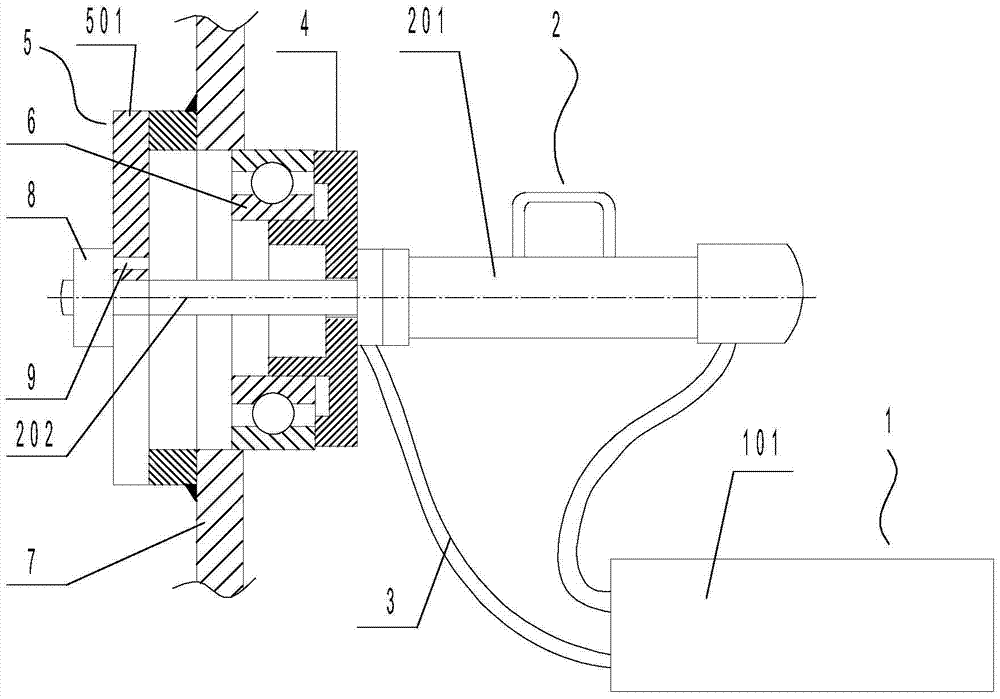

Embodiment 1

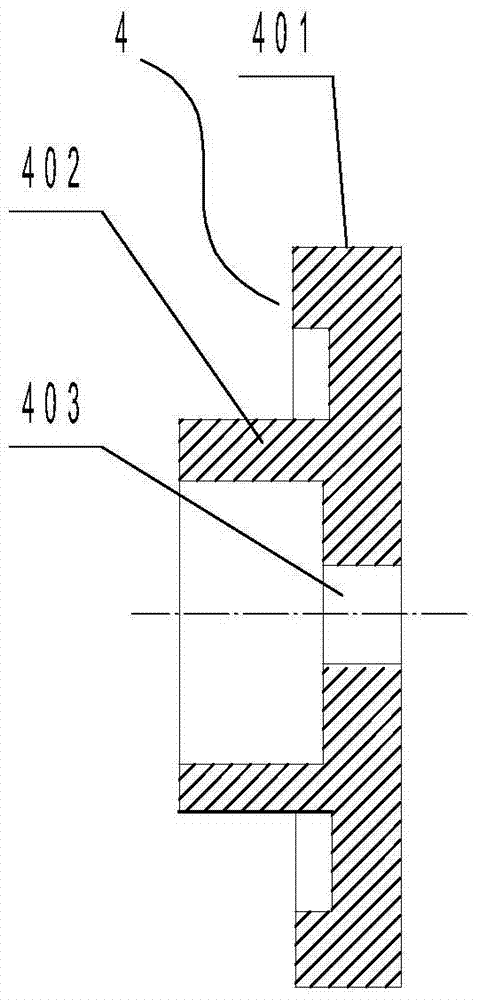

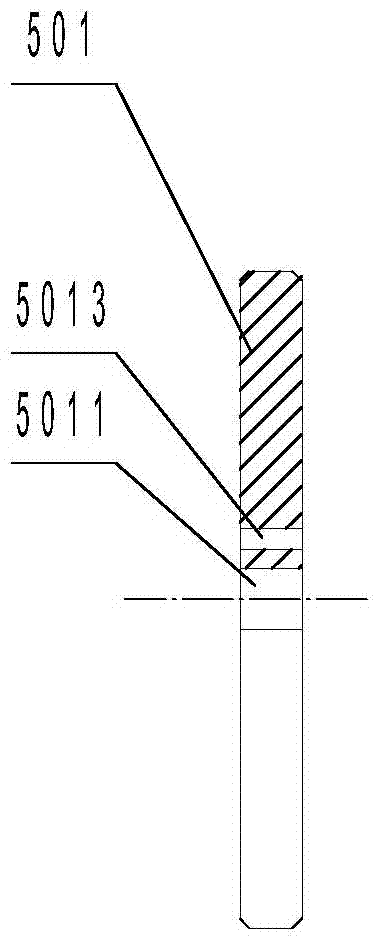

[0039] A portable bearing hydraulic assembly and disassembly device, including a hydraulic system 1, a working cylinder 2, a pressure plate 4, and a backing plate 5, the hydraulic system 1 includes an oil tank 101, and the working cylinder 2 includes an oil cylinder barrel 201 and a piston rod 202. The piston rod 202 is installed in the oil cylinder 201, and the oil cylinder 201 and the oil tank 101 are connected together through the hose 3; the pressure plate 4 is located on one side of the base frame 7 where the bearing 6 is installed, and one end of the pressure plate 4 is inserted into the bearing 6 , the other end is in contact with the end of the cylinder barrel 201 of the working cylinder 2; the backing plate 5 is located on the other side of the base frame 7, and the extended end of the piston rod 202 of the working cylinder 2 extends out of the cylinder barrel 201 and passes through it in turn The pressing plate 4, the base frame 7, the backing plate 5 are connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com