A fluorine-containing emulsifier, anionic fluorine-containing emulsion and method prepared based on the emulsifier

An anionic, emulsifier technology, applied in the field of fine chemicals, can solve the problems of unfavorable surface properties and environment of fluorine-containing emulsions, harsh reaction conditions, etc., and achieve the effect of saving resources and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

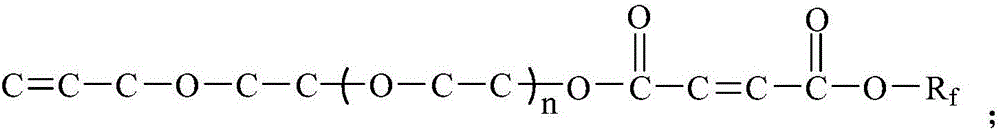

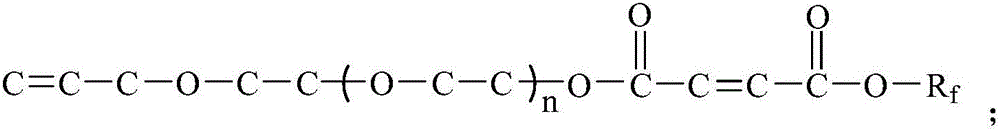

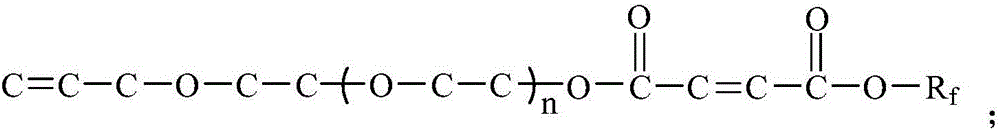

Image

Examples

preparation example Construction

[0032] A preparation method of anionic fluorine-containing emulsion, comprising the following steps:

[0033] 1) Raw materials: fluorine-containing acrylate, butyl acrylate, styrene, acrylic acid or 2-acrylamide-2-methylpropanesulfonic acid, emulsifier, initiator and water.

[0034] Wherein, the molar ratio of the polymerized monomer fluorine-containing acrylate, butyl acrylate, styrene, acrylic acid or 2-acrylamide-2-methylpropanesulfonic acid is 0.2-1.0:1.0:1.0:0.02-0.4; the emulsifier accounts for 0.5%-5% of the total mass of the polymerized monomers; the initiator accounts for 0.1-2% of the total mass of the polymerized monomers; water accounts for 200%-300% of the total mass of the polymerized monomers.

[0035] 2) Add all kinds of above-mentioned raw materials (among them: 70% of water is added, and the remaining 30% is used for later use), put into a container and shear at high speed for 30 minutes to obtain a pre-emulsion.

[0036] 3) Add the remaining 30% water and 5...

Embodiment 1

[0040] An anionic fluorine-containing emulsion, its raw material components and consumption are as follows:

[0041] Fluorinated acrylate, butyl acrylate, styrene, acrylic acid, emulsifier (-R f For: -C 4 h 3 f 6 O), ammonium persulfate and water; wherein: the molar ratio of fluorine-containing acrylate, butyl acrylate, styrene, and acrylic acid is 0.7:1.0:1.0:0.02; emulsifier (-R f For: -C 4 h 3 f 6 O) accounts for 1.0% of the total mass of the polymerized monomers; ammonium persulfate accounts for 0.2% of the total mass of the polymerized monomers; water accounts for 220% of the total mass of the polymerized monomers.

[0042] The preparation process of the anionic fluorine-containing emulsion:

[0043]Add all kinds of above-mentioned raw materials (70% of which is added with water, and the remaining 30% for later use) into a container and shear at high speed for 30 minutes to obtain a pre-emulsion. Add the remaining 30% water and 5% pre-emulsion in a dry three-necke...

Embodiment 2

[0045] An anionic fluorine-containing emulsion, its raw material components and consumption are as follows:

[0046] Fluorinated acrylate, butyl acrylate, styrene, 2-acrylamide-2-methylpropanesulfonic acid, emulsifier (-R f For: -C 4 h 3 f 6 O), ammonium persulfate and water; wherein: the molar ratio of fluorine-containing acrylate, butyl acrylate, styrene, and 2-acrylamide-2-methylpropanesulfonic acid is 0.5: 1.0: 1.0: 0.4; emulsifier ( -R f For: -C 4 h 3 f 6 O) accounts for 2.2% of the total mass of the polymerized monomers; ammonium persulfate accounts for 1.1% of the total mass of the polymerized monomers; water accounts for 230% of the total mass of the polymerized monomers.

[0047] The preparation process of the anionic fluorine-containing emulsion:

[0048] Add all kinds of above-mentioned raw materials (70% of which is added with water, and the remaining 30% for later use) into a container and shear at high speed for 30 minutes to obtain a pre-emulsion. Add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com