A cationic fluorine-containing emulsion and its preparation method

A cationic and emulsion technology, applied in the field of fine chemicals, can solve problems such as harsh reaction conditions, achieve stable performance and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of cationic fluorine-containing emulsion, comprising the following steps:

[0031] 1) Raw materials: fluorine-containing acrylate, butyl acrylate, styrene, dimethylaminoethyl methacrylate or methacryloyloxyethyltrimethylammonium chloride, emulsifier, initiator and water.

[0032] Wherein, the molar ratio of the polymerized monomer fluorine-containing acrylate, butyl acrylate, styrene, dimethylaminoethyl methacrylate or methacryloyloxyethyltrimethylammonium chloride is 0.2-1.0:1.0: 1.0:0.1-0.4; the emulsifier accounts for 0.5%-5% of the total mass of the polymerized monomers; the initiator accounts for 0.1%-2% of the total mass of the polymerized monomers; water accounts for 200%-300% of the total mass of the polymerized monomers.

[0033] 2) Add all kinds of above-mentioned raw materials (among them: 70% of water is added, and the remaining 30% is used for later use), put into a container and shear at high speed for 30 minutes to obtain a pre-emulsi...

Embodiment 1

[0038] A cationic fluorine-containing emulsion, its raw material components and consumption are as follows:

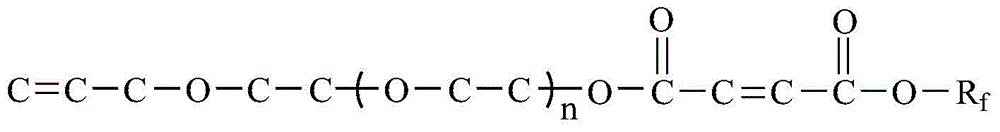

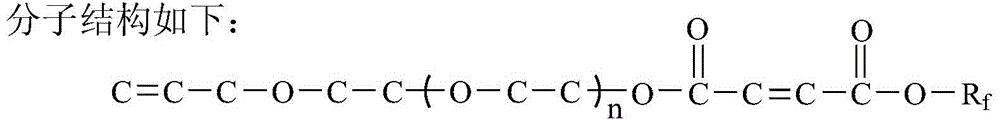

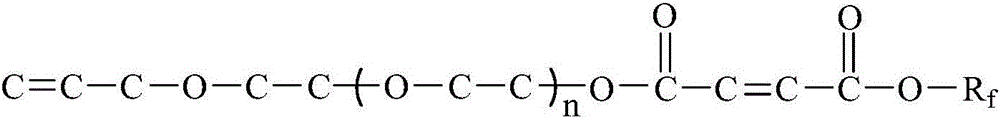

[0039] Fluorine-containing acrylate, butyl acrylate, styrene, dimethylaminoethyl methacrylate, emulsifier (-Rf is: -C 4 h 3 f 6 O), ammonium persulfate and water; wherein: the molar ratio of fluorine-containing acrylate, butyl acrylate, styrene, and dimethylaminoethyl methacrylate is 0.5:1.0:1.0:0.1; emulsifier (-Rf is :-C 4 h 3 f 6 O) accounts for 0.6% of the total mass of the polymerized monomers; ammonium persulfate accounts for 0.2% of the total mass of the polymerized monomers; water accounts for 210% of the total mass of the polymerized monomers.

[0040] The preparation process of the cationic fluorine-containing emulsion:

[0041] Add all kinds of above-mentioned raw materials (70% of which is added with water, and the remaining 30% for later use) into a container and shear at high speed for 30 minutes to obtain a pre-emulsion. Add the remaining 30% wate...

Embodiment 2

[0043] A cationic fluorine-containing emulsion, its raw material components and consumption are as follows:

[0044] Fluorine-containing acrylate, butyl acrylate, styrene, methacryloyloxyethyltrimethylammonium chloride, emulsifier (-Rf is: -C 4 h 3 f 6O), ammonium persulfate and water; wherein: the molar ratio of fluorine-containing acrylate, butyl acrylate, styrene, and methacryloxyethyltrimethylammonium chloride is 0.2:1.0:1.0:0.3; emulsifier (-Rf is: -C 4 h 3 f 6 O) accounts for 0.9% of the total mass of the polymerized monomers; ammonium persulfate accounts for 0.7% of the total mass of the polymerized monomers; water accounts for 240% of the total mass of the polymerized monomers.

[0045] The preparation process of the cationic fluorine-containing emulsion:

[0046] Add all kinds of above-mentioned raw materials (70% of which is added with water, and the remaining 30% for later use) into a container and shear at high speed for 30 minutes to obtain a pre-emulsion. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com