Pig-origin bacillus amyloliquefaciens spray drying technology

A technology of amylolysis spores and drying process, which is applied in the direction of bacteria and preserved microorganisms, and can solve the problems of low survival rate of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

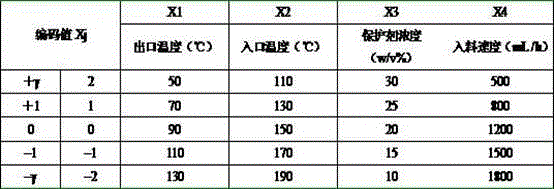

[0009] Specific embodiment one: a spray drying process of porcine-derived Bacillus amyloliquefaciens, characterized in that: the first step is to prepare the porcine-derived Bacillus amyloliquefaciens cell fermentation liquid; Adding the protective agent that concentration is 20% (W / V) in the Bacillus amylobacter thalline fermented liquid; The 3rd step, carry out spray drying by spray drier, setting parameter is: feeding speed is 1200mL / h, and inlet temperature is 150°C, the outlet temperature is 90°C.

[0010] The second specific embodiment is a further description of the spray drying process of the porcine-derived Bacillus amyloliquefaciens described in the first specific embodiment. It is 3g of sucrose, 10g of skimmed milk powder, 2g of sorbitol, 2g of fructo-oligosaccharide, and 3g of glycerin.

[0011] The third specific embodiment is a further description of the spray drying process of the porcine-derived Bacillus amyloliquefaciens described in the first specific embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com