Enhancing method for producing malic acid through biological electrodialysis

A technology of bioelectrodialysis and malic acid, which is applied in the field of bioelectrodialysis, can solve the problems of product impurity and low energy, and achieve the effects of improving operating efficiency and effect, reducing energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

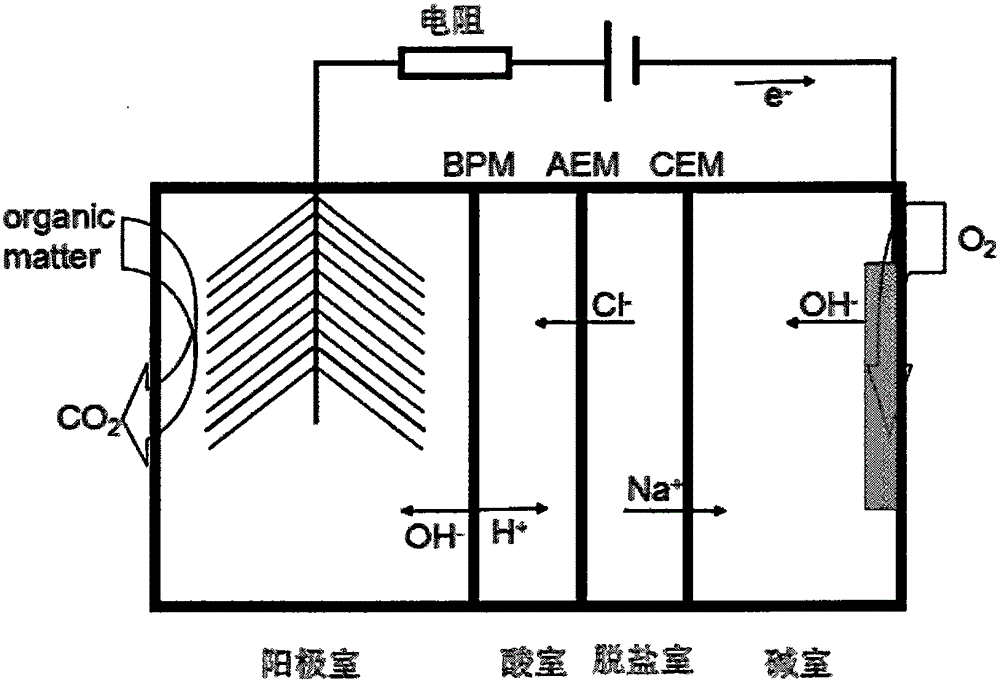

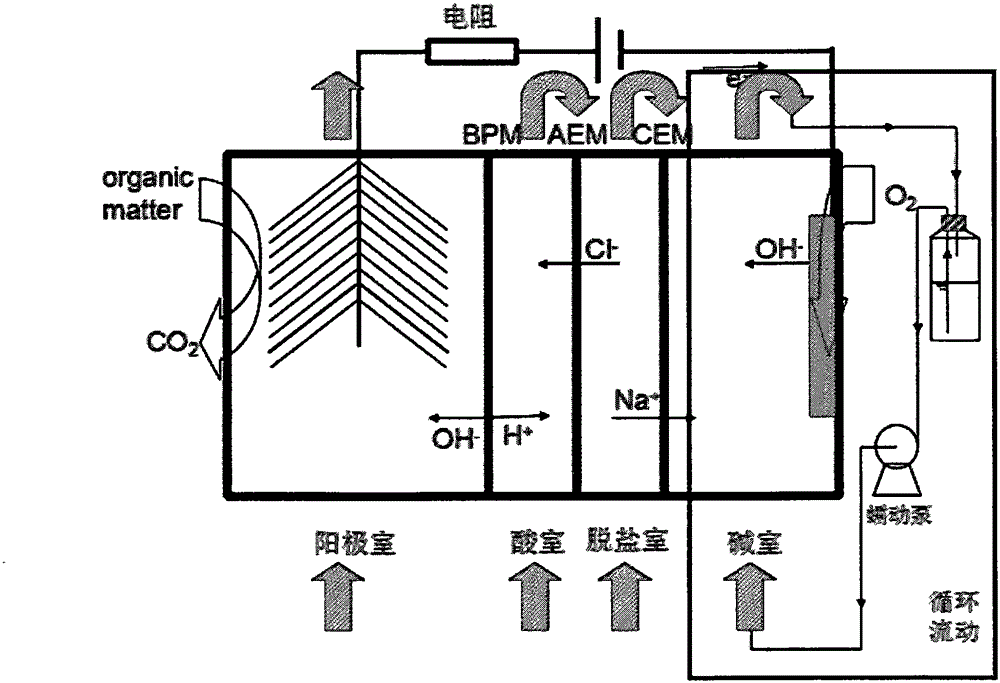

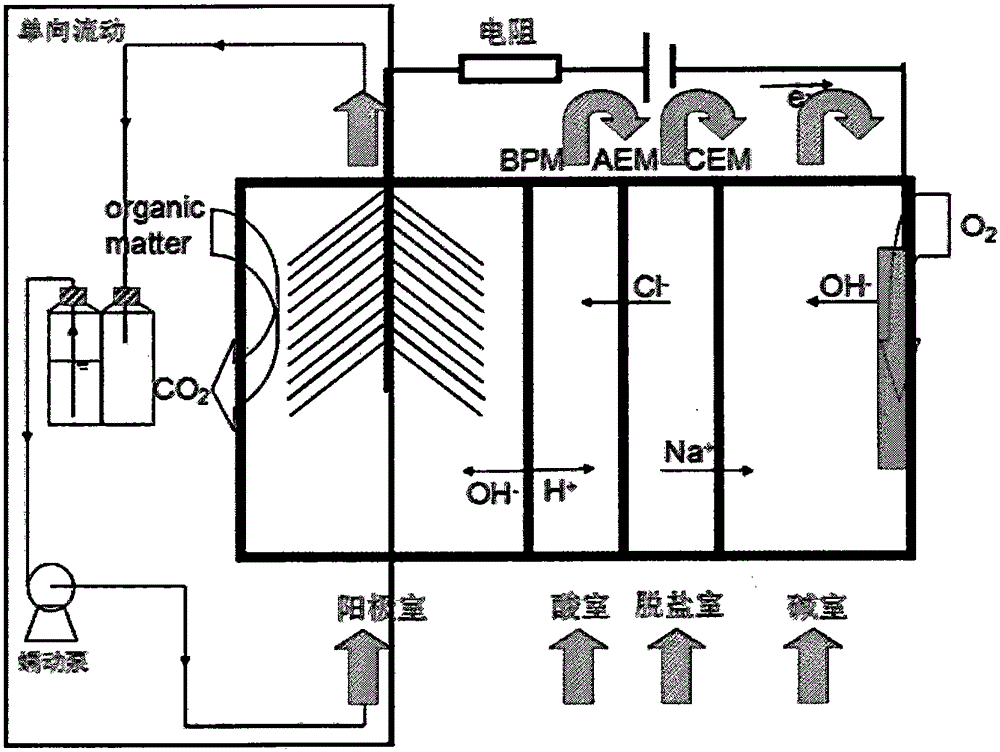

[0021] Such as figure 1 , 2 As shown in , 3, the continuous flow bioelectrodialysis device is connected to the reactor in the constant temperature box through a multi-channel peristaltic pump and pipelines, so that the liquid in the reactor flows. Connect the pipeline to the peristaltic pump in the discontinuous state, and turn on the peristaltic pump when the reactor reaches the plateau of discontinuous operation, so that the continuous flow bioelectrodialysis can run stably, and its operation cycle is set to 24 hours. During the operation of continuous flow, the continuous flow operation modes of the four reaction chambers are different, in which the anode chamber adopts the unidirectional flow mode, while the remaining three chambers adopt the circulation flow mode. The anode chamber feed liquid is the matrix, the acid chamber circulation fluid is 0.04mol / L L-malic acid solution with a total volume of 100mL, and the middle chamber circulation fluid is 0.3mol / L potassium L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com