A bubble electrospinning device

A technology of bubble electrospinning and bubbles, applied in the field of spinning, can solve the problems of spinning liquid exposed to the air, achieve good shape, avoid pollution, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

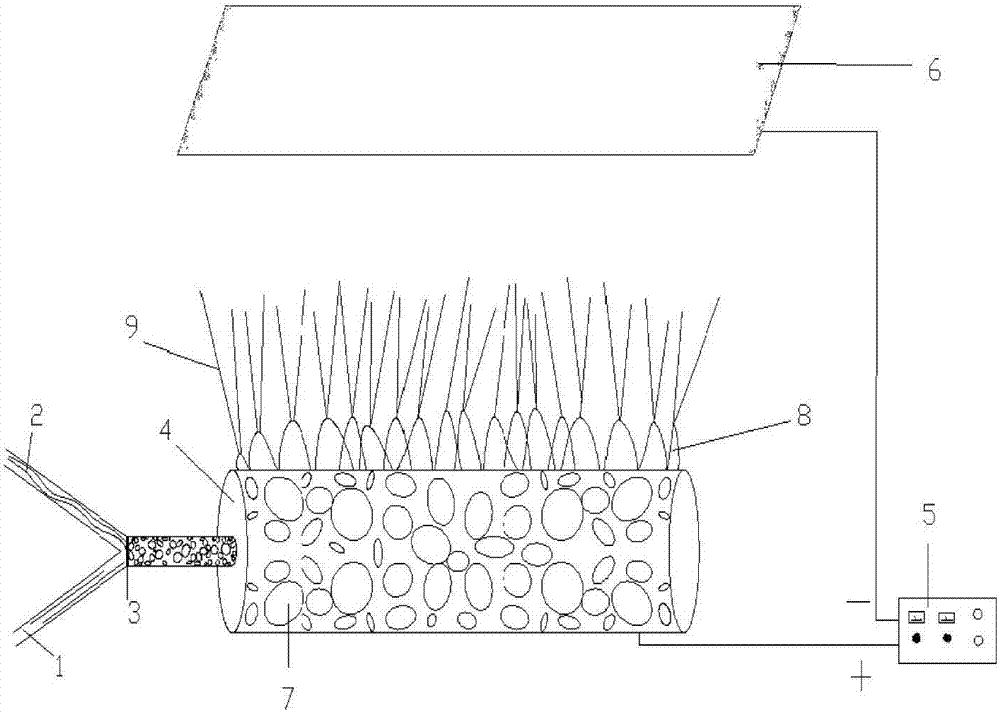

[0023] The invention discloses a bubble electrostatic spinning device, which is used to solve the problem that the spinning solution of the existing bubble electrostatic spinning device is exposed to the air. The bubble electrospinning device designs the bubble generating device as a closed space, which avoids the influence of solvent volatilization on the concentration of the spinning solution and the pollution to the environment; through the mutual cooperation between the liquid inlet volume, the ventilation volume and the metal mesh, more uniform Bubbles; the design of the metal coiled liquid storage tube reduces the generation of droplets during the spinning process, making the prepared nanofibers have better morphology.

[0024] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com