A Method for Determining Rigidity Matching of Underpass Railway Engineering

A railway engineering and stiffness technology, which is applied in the field of determining the stiffness matching of underpassing railway engineering, can solve the problems of unreasonable foundation reinforcement scheme, unsatisfactory reinforcement effect, and lack of design basis for the scheme, so as to reduce soil disturbance and reduce The effect of differential settlement of subgrade and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

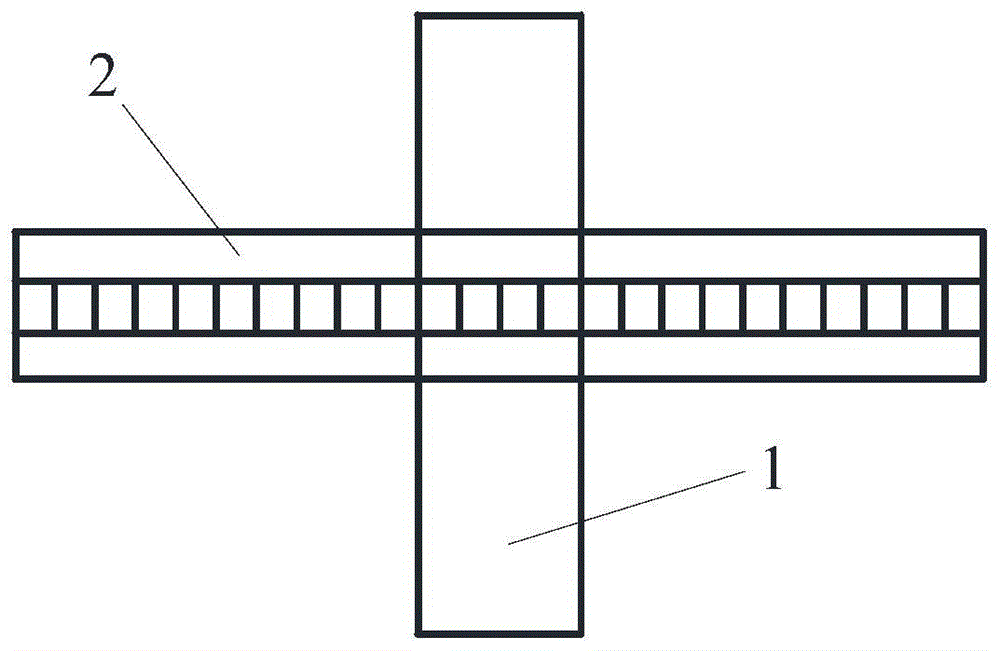

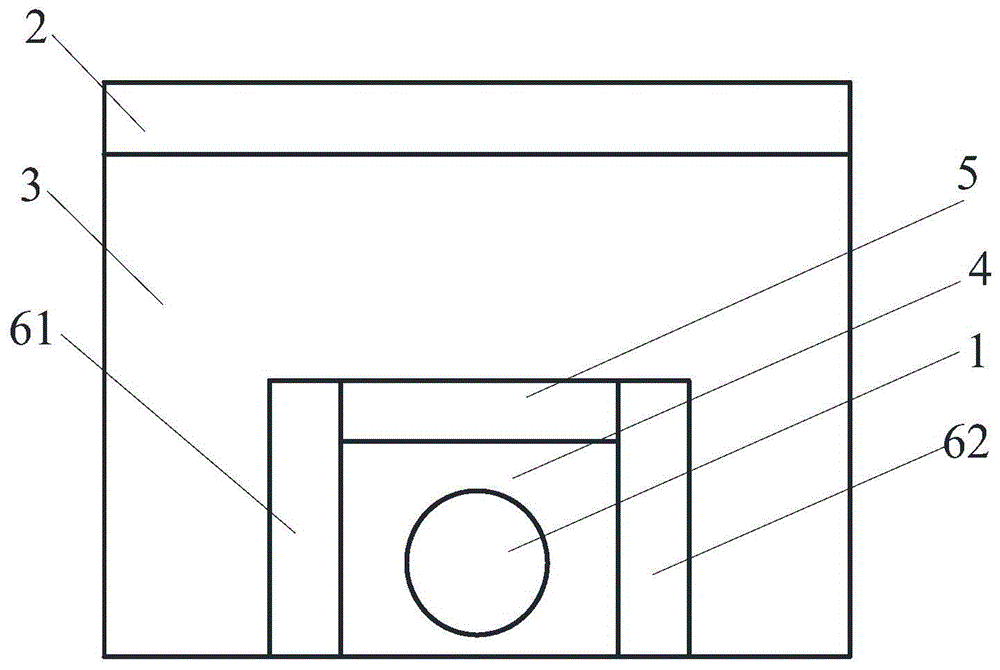

[0024] The proposed single-line shield tunnel 1 crosses the railway subgrade 2 orthogonally (such as figure 1 as shown, figure 1 It is a schematic plan view of a method for determining stiffness matching of an underpass railway project according to an embodiment of the present invention. ), determine the geotechnical engineering properties within the appropriate depth range under the subgrade, and the specific parameters of the geotechnical engineering properties include soil modulus, cohesion or internal friction angle, etc. The outer diameter of the shield tunnel is 6.2m, the inner diameter is 5.5m, the segment ring width is 1.2m, and the buried depth at the top is 15m. The shield tunneling railway project is located in a soft soil area, where there is a deep clay layer, and the compression modulus of the undisturbed soil body 3 is about E s = 6MPa.

[0025] In the actual construction of the shield passing through the railway project, the application of the present invent...

Embodiment 2

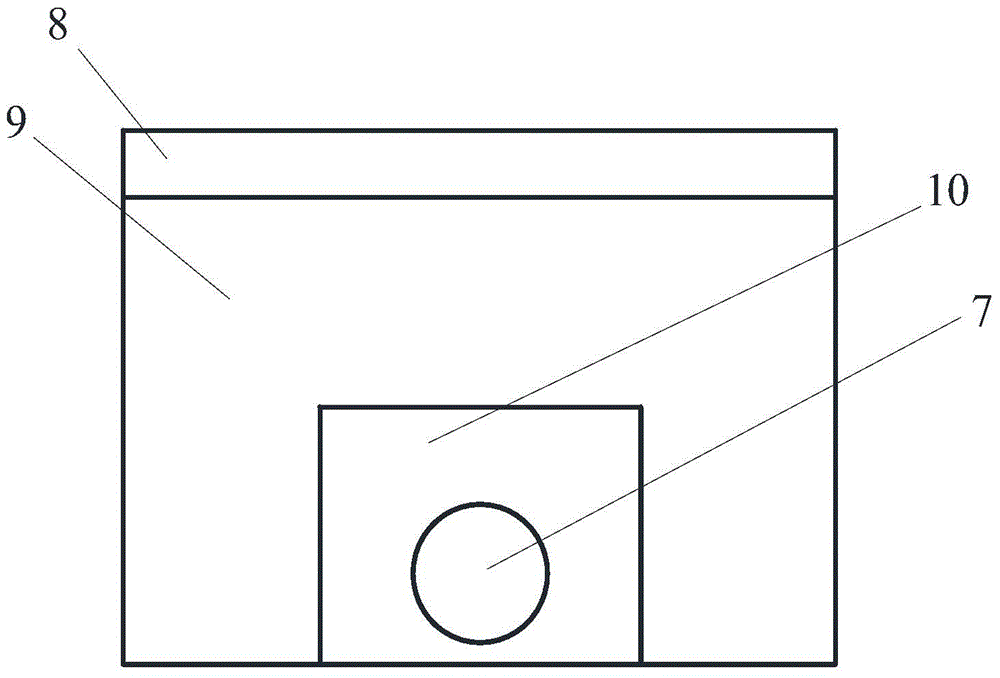

[0032] The proposed single-line shield tunnel crosses the railway embankment orthogonally, and the geotechnical engineering properties within the appropriate depth range under the embankment are determined. The specific parameters of the geotechnical engineering properties include soil modulus, cohesion or internal friction angle, etc. The outer diameter of the shield tunnel is 6.2m, the inner diameter is 5.5m, the segment ring width is 1.2m, and the buried depth at the top is 12m. The shield tunneling railway project is located in a soft soil area, where there is a deep and thick clay layer, and the compression modulus of the undisturbed soil is about E s = 6 MPa.

[0033] In the actual construction of the shield passing through the railway project, the application of the present invention to carry out the stiffness matching design specifically includes the following steps:

[0034] In the direction of the tunnel cross section, the soil around the tunnel is matched with the ...

Embodiment 3

[0041] The proposed single-line shield tunnel crosses the railway embankment orthogonally, and the geotechnical engineering properties within the appropriate depth range under the embankment are determined. The specific parameters of the geotechnical engineering properties include soil modulus, cohesion or internal friction angle, etc. The outer diameter of the shield tunnel is 6.2m, the inner diameter is 5.5m, the segment ring width is 1.2m, and the buried depth at the top is 18m. The shield tunneling railway project is located in a soft soil area, where there is a deep and thick clay layer, and the compression modulus of the undisturbed soil is about E s = 6 MPa.

[0042] In the actual construction of the shield passing through the railway project, the application of the present invention to carry out the stiffness matching design specifically includes the following steps:

[0043] In the direction of the tunnel cross section, the soil around the tunnel is matched with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com