Multifunctional construction auxiliary ship structure for steel pipe piles

A steel pipe pile, multi-functional technology, applied in basic structure engineering, sheet pile wall, construction and other directions, can solve the problems of insufficient barge carrying capacity, large additional cost of auxiliary ships, etc., to improve construction safety, large loading capacity, work Safe and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

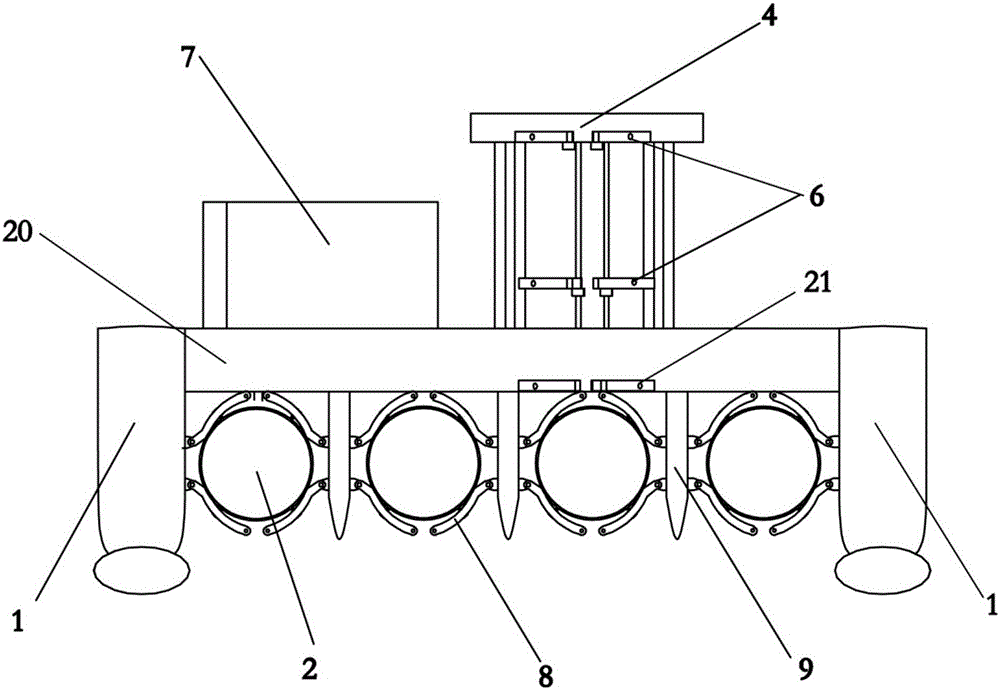

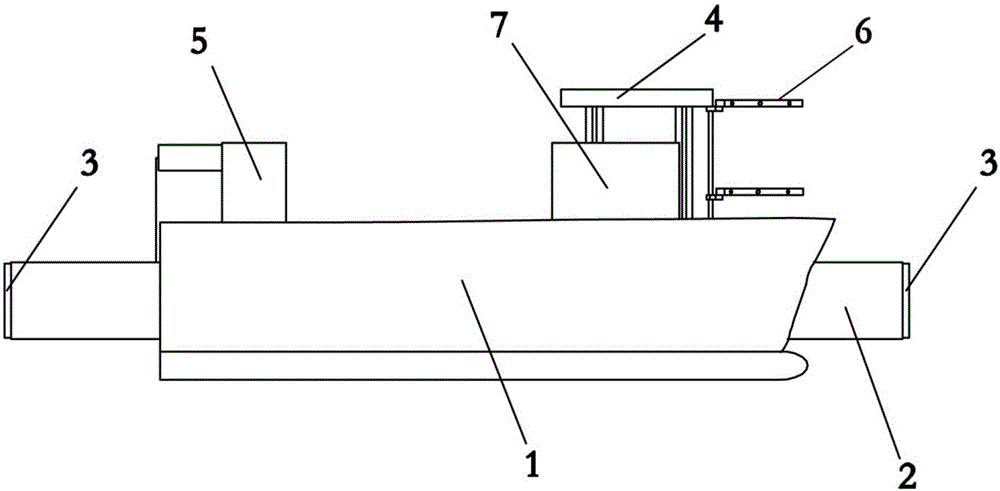

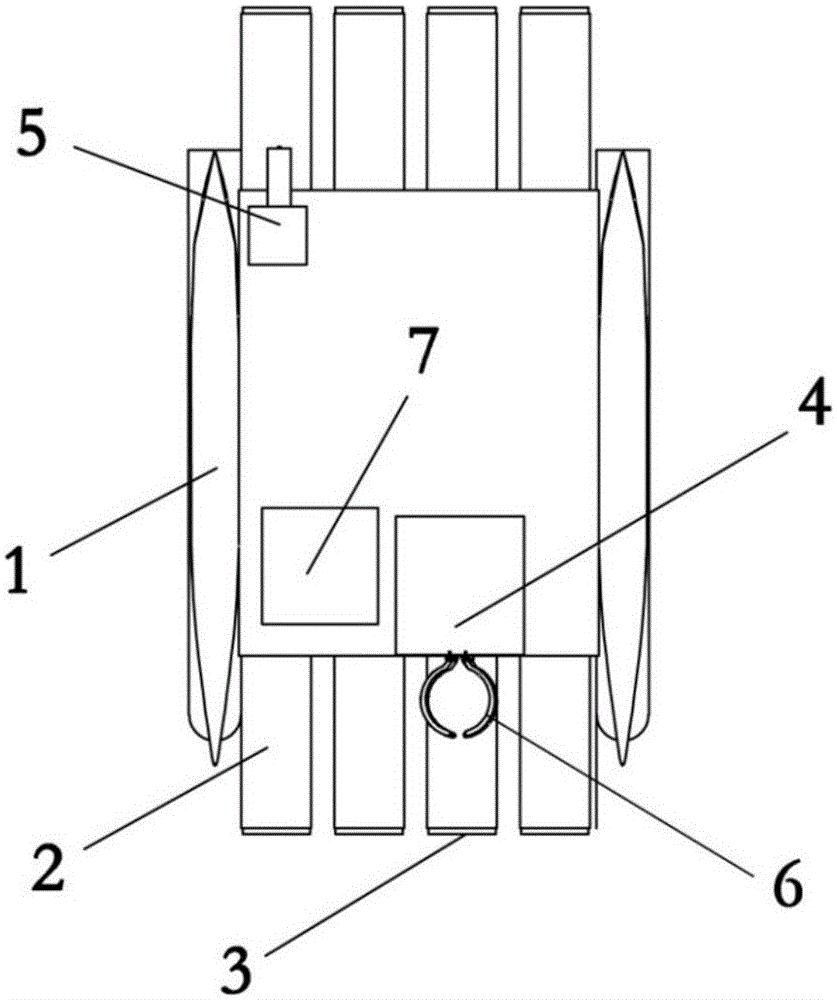

[0023] Such as Figures 1 to 3 As shown, a steel pipe pile multifunctional construction auxiliary ship structure according to the present invention includes a hull 20 and steel pipe piles 2, the two sides of the hull 20 are fixedly connected with a sheet body 1, and the top of the hull 20 is provided with a guide frame 4 and a mechanical arm. 5 and the superstructure 7, the bottom of the hull 20 is provided with a pile holding device, and the steel pipe pile 2 is correspondingly arranged with the pile holding device.

[0024] The above constitutes the basic structure of the present invention.

[0025] The hull 20 of the present invention is designed with a small waterplane area catamaran as a parent ship and combined with the advantages of a semi-submersible platform to achieve multi-functionality and safe and stable work. The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com