Assembled integral type masonry wall assembling structure and construction method thereof

A construction method and integrated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult control of construction quality, insufficient labor, and large amount of wet work on site, so as to improve on-site construction conditions and meet functional requirements. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

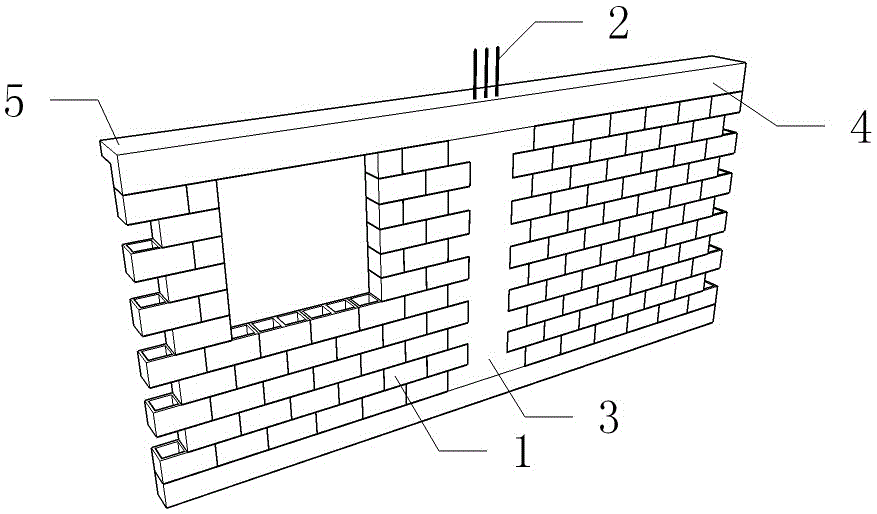

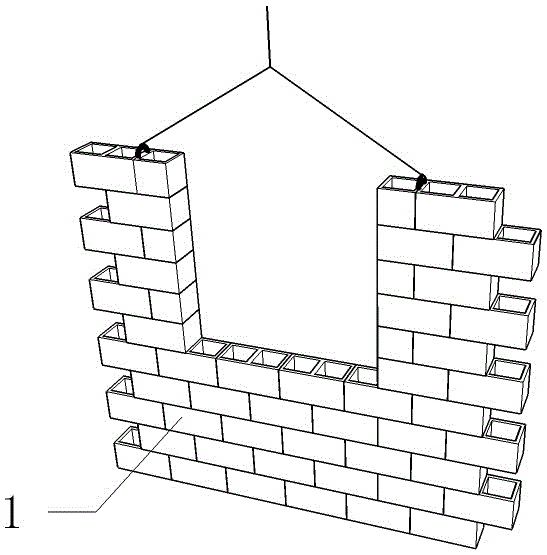

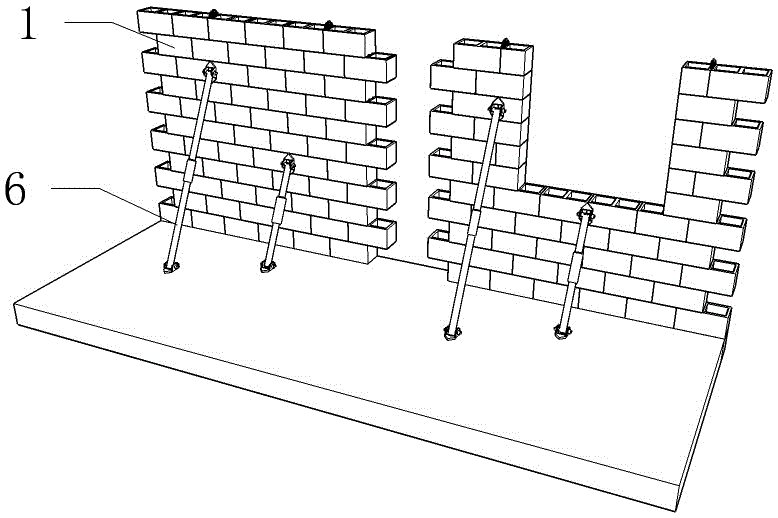

[0023] An assembled monolithic masonry wall assembly structure and its construction method. It is composed of prefabricated masonry wall pieces, reinforced concrete structural columns, and cast-in-place ring beam floor slabs. The prefabricated masonry wall pieces are built with concrete hollow blocks in the factory according to requirements. It is built by machine spraying and machine masonry. There are horse-toothed bars at the ends of the wall pieces. After the adjacent wall pieces are hoisted in place, steel bars are placed in the horse-toothed bars between them, and concrete is poured to form structural columns. The upper part of the wall is a cast-in-place ring beam, and its construction steps include:

[0024] a. Before the wall piece is hoisted, check the number of the wall piece and check whether the wall piece is intact;

[0025] b. Measure the setting-out to determine the position of the wall piece, such as figure 2 , hoist the wall piece to the structural installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com