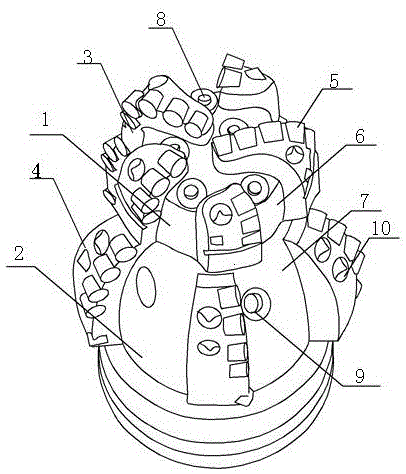

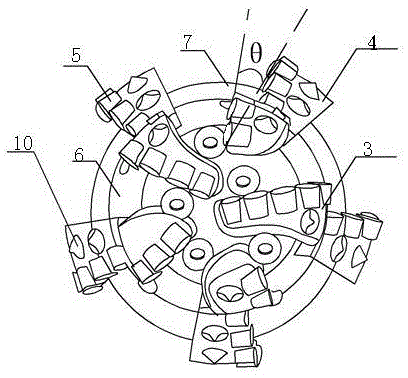

Double-stage drill bit

A drill bit and eye-piercing technology, which is applied to drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as unreasonable design, fast cutting tooth wear, and cutting tooth cracking, so as to improve abrasive resistance, reduce wear, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Drilling environment and progress of two-stage drill bit: 3260-3640m underground in the igneous rock of the Yingcheng Formation in Changling, Northeast China, and the footage is 380m;

[0026] Drilling time of two-stage drill bit: pure drilling time 78.5h, mechanical drilling speed 4.84 / h;

[0027] The above data show that the two-stage drill bit of the present invention has greatly improved the ROP and the service life of the drill bit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com