Horizontal and perpendicular strip-shaped stone cutting machine

A stone cutting machine and bar-shaped technology, which is applied in open-pit mining, earth square drilling, special mining, etc. It can solve the problems of not easy to replace parts and wearing parts, difficult to maintain and repair equipment, and long time to cut stones. , to achieve the effects of easy maintenance, prevention of safety liability accidents, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

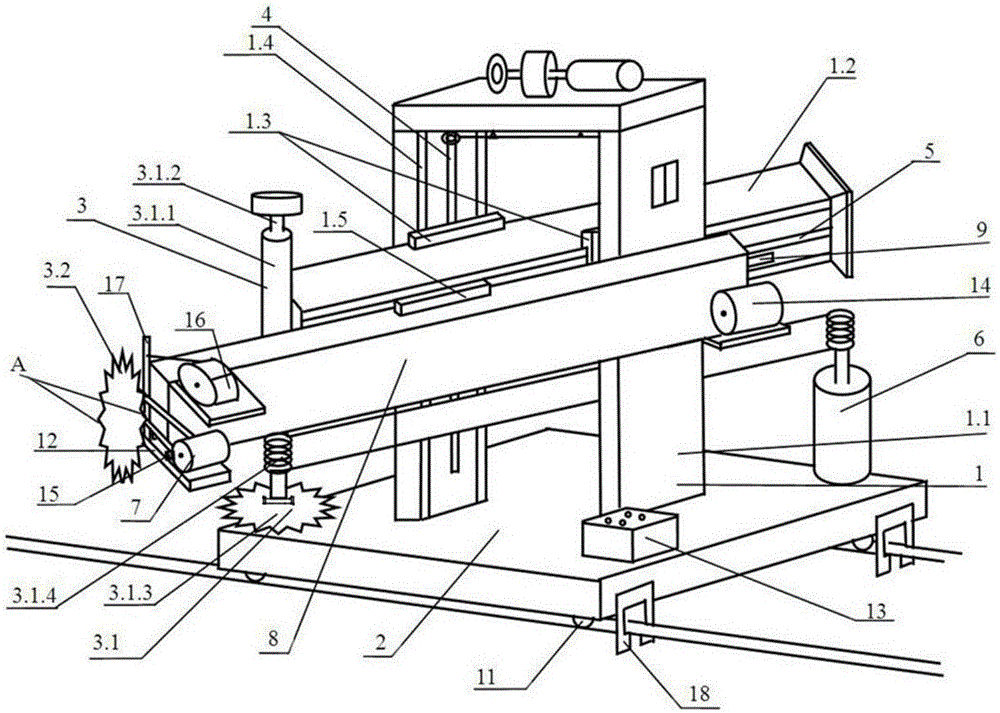

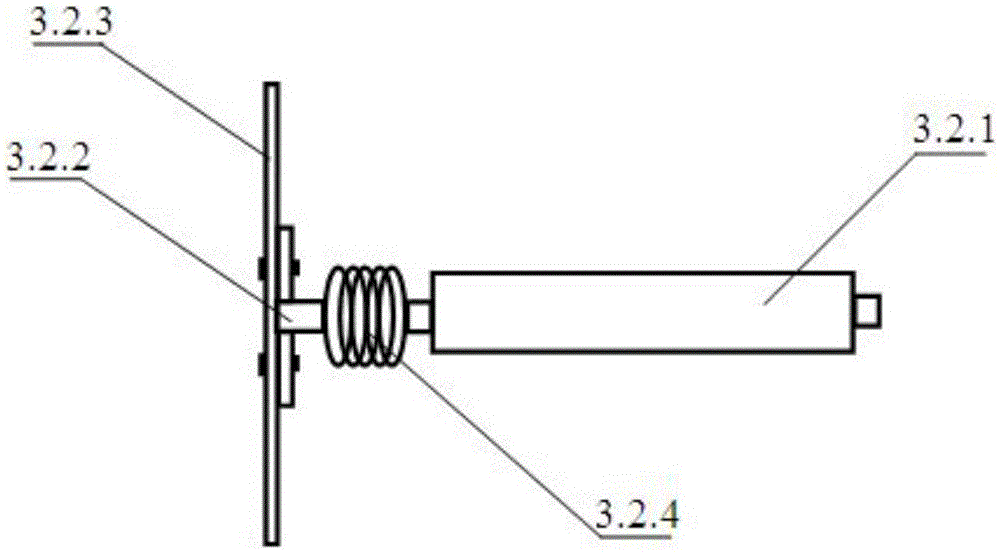

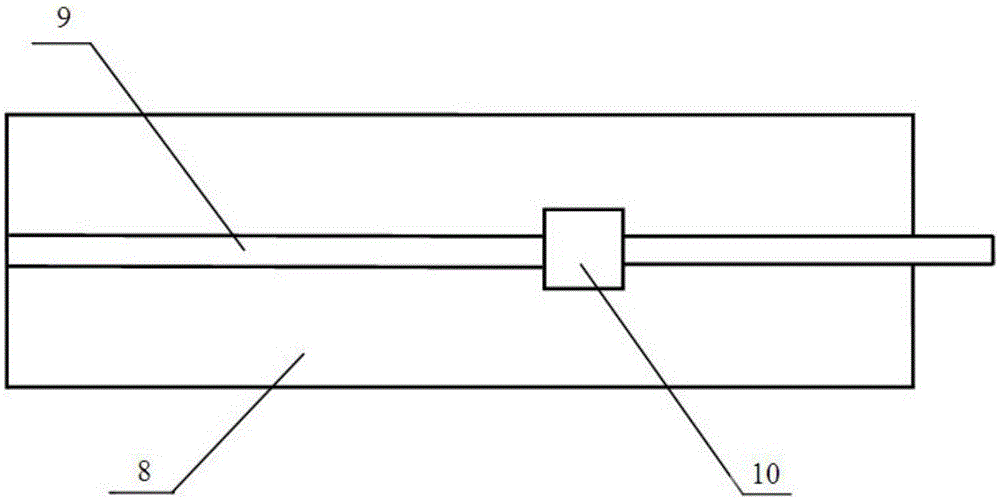

[0030] See figure 1 , figure 2 and image 3 , a horizontal and vertical strip stone cutter, including a frame, a working platform, a tool holder system, a motor, a traveling mechanism and a control cabinet; the control cabinet is installed on the working platform; the frame fixed on the working platform is composed of a vertical longitudinal The mobile frame, the horizontal mobile frame connected to the vertical mobile frame, the knife frame system fixed on the horizontal mobile frame and the traveling mechanism; the vertical mobile frame and the lateral mobile frame are connected by cross dovetail sliding block A; The cross dovetail sliding block A is stuck on the slide rail fixed on the vertical moving frame;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com