Intelligent metering pry and metering method thereof

A metering method and technology of metering skid, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as difficulty in meter reading, improvement of unfavorable processes, reduction of energy consumption, and large production-to-sales ratio of gas companies. , to achieve the effect of being conducive to management and maintenance, reducing subsequent operating costs, and reducing the cost of manual meter reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

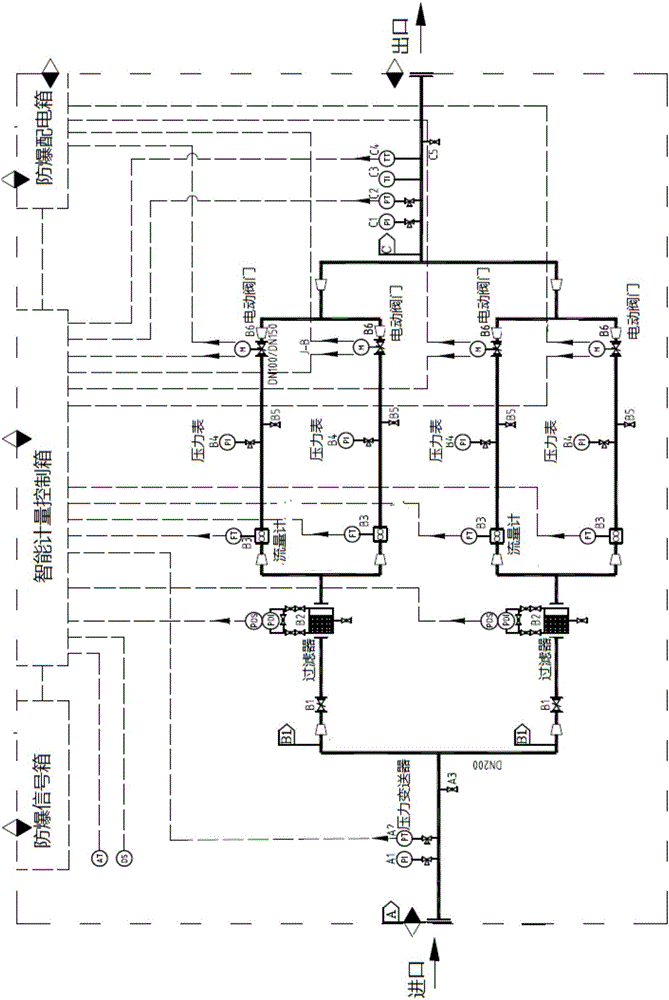

[0034] see figure 1 , an intelligent metering skid, including an air intake main pipe, the air intake main pipe communicates with at least two air intake branch pipes, each air intake branch pipe is provided with a filter B2, and the filter B2 filters the upstream air and divides it into two Metering branch, each metering branch is equipped with a flow meter B3 and an electric cut-off valve B6 behind the flow meter; the two metering branches are combined into one outlet branch pipe, and each outlet branch pipe is combined into one outlet main pipe; intelligent metering control is also included The intelligent metering control box is connected with the signal of the filter B2, the flow meter B3, and the electric cut-off valve B6, and the flow meter B3 transmits the flow data signal to the intelligent metering control box, and the intelligent met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com