Sampling device for laboratory test of sludge solidification treatment and sampling method thereof

A technology of sludge solidification and treatment chamber, which is applied in the preparation of test samples, etc., can solve the problems of lack of safe disposal methods for sludge and has not been well solved, and achieves the effect of simple, fast, convenient and practical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

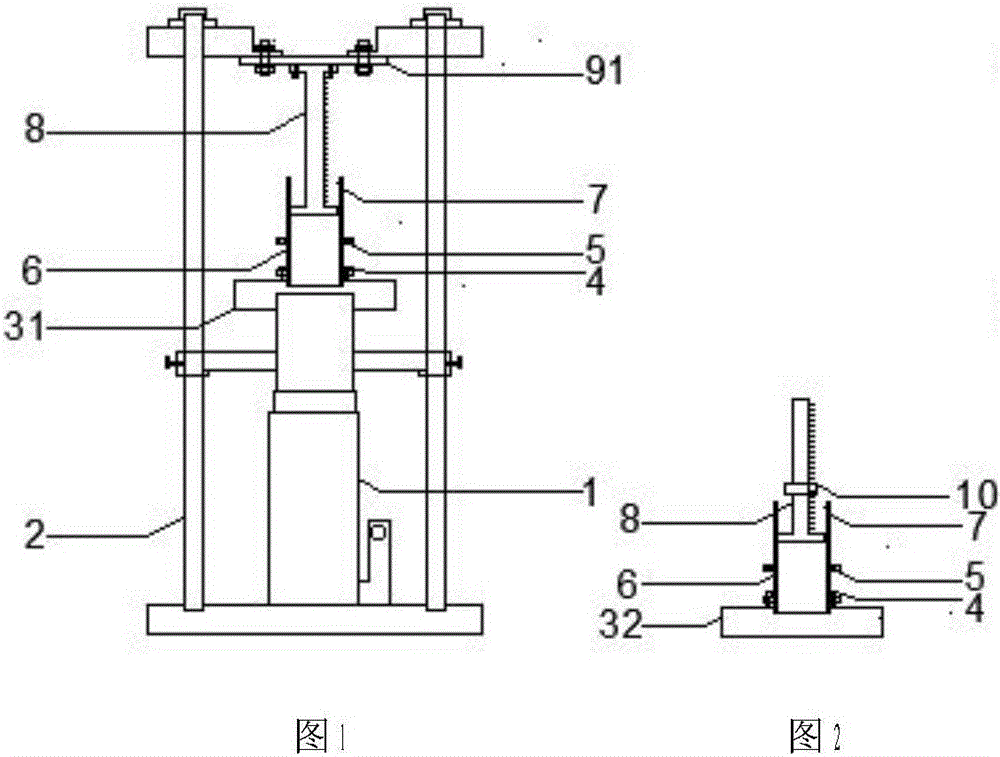

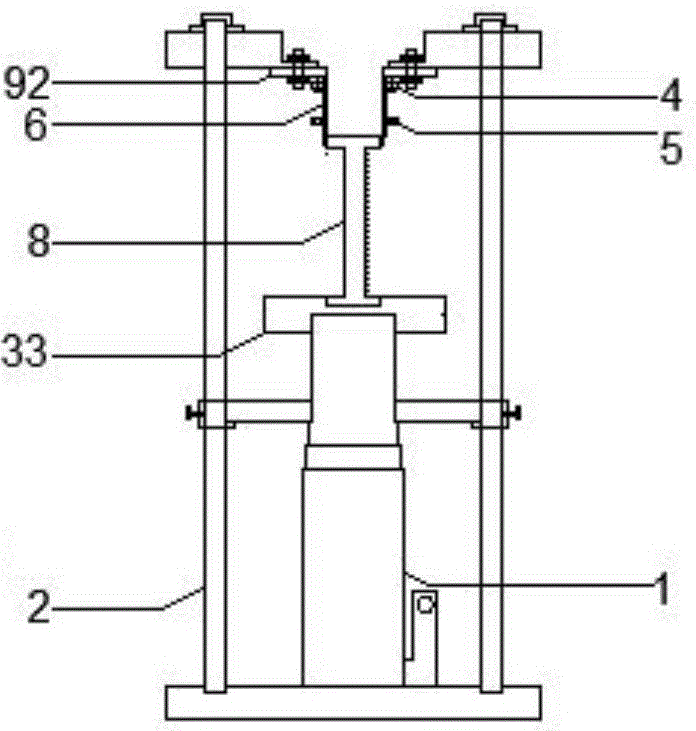

[0033] The static pressing device of this embodiment is as follows figure 1 As shown, the base 31 of the static pressing device is a two-way base, the lower middle position is a circular fixing groove, the upper middle position is also a circular fixing groove, and both sides of the upper part have threaded round holes; The reaction force top plate 91 adopts a solid circular plate; the base 31 of the static pressing device is installed on the jack 1, the jack 1 and the reaction force top plate 91 of the static pressing device are all installed on the fixed bracket 2, and the split die 6 is installed on the static On the base 31 of the pressing sample device, the split mold 6 has an upper clamp ring 5 and a lower clamp ring 4, a mold protector 7 is installed above, and the force transmission guide rod 8 extends into the split mold 6 from above, relying on the jack 1. pressure for static pressing.

[0034] Compact sample preparation device such as figure 2As shown, the base 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com