Method for measuring operating insulator contamination degree

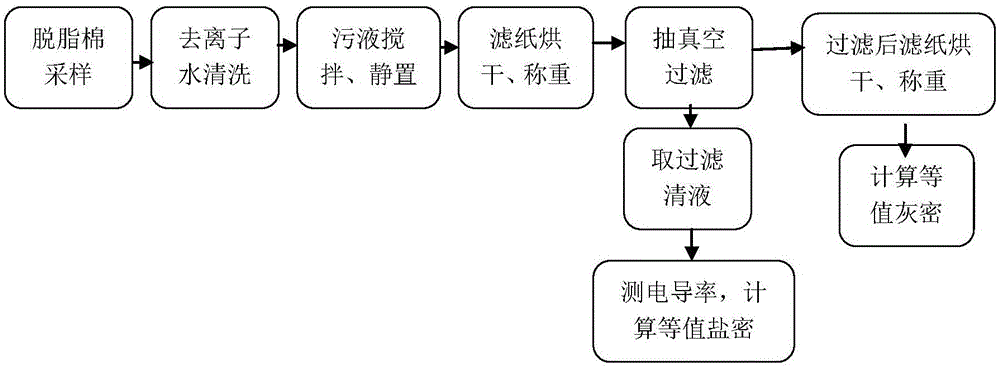

A measurement method and technology for insulators, which are applied in the direction of material absorption and weighing, material impedance, etc., can solve the problems of long filtration time and inconvenient insulator pollution sampling, and achieve the improvement of measurement accuracy, shorten pollution measurement time, and speed up pollution filtering speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

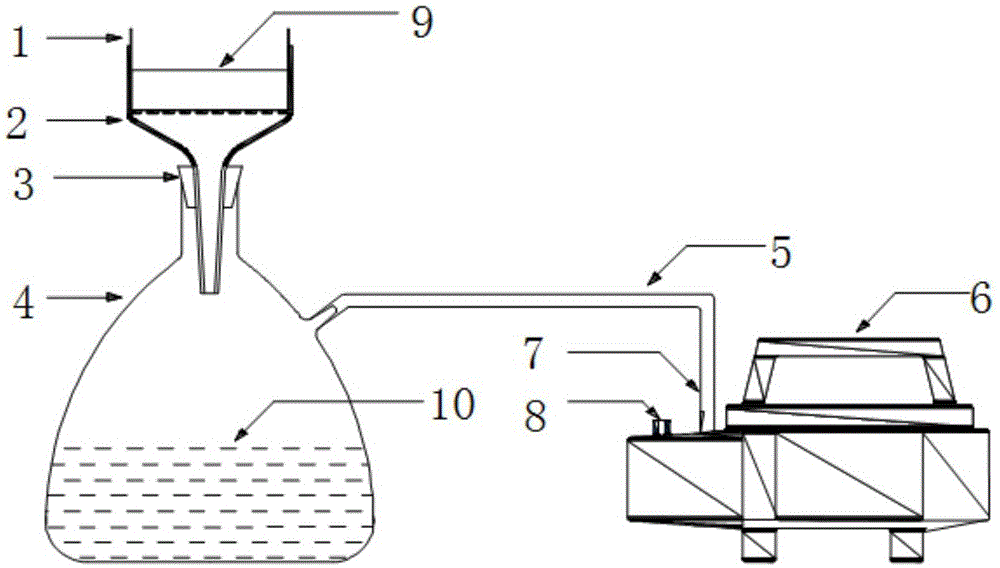

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Measurement of pollution degree of a bell jar type porcelain insulator coated with RTV paint:

[0037] 1) Sampling:

[0038] Use alcohol-containing absorbent cotton to scrub the upper and lower surfaces of the insulator respectively, and the scrubbing time is 10 minutes, so as to ensure that the insoluble contamination has enough time to dissolve in alcohol. Put the absorbent cotton containing dirt into the sample bag and seal it for the equivalent salt density and gray density test.

[0039] 2) Cleaning:

[0040] Take 500ml of deionized water (the specific water consumption can be determined according to the degree of contamination of the absorbent cotton), use 200ml of deionized water to wash the contaminated absorbent cotton for the first time, wring out the absorbent cotton; then use 200ml of deionized water to wash the absorbent cotton for the second time, and put Wring out the absorbent cotton after cleaning. The container was rinsed with 50 ml of de...

Embodiment 2

[0045] Example 2: Measurement of pollution degree of large and small umbrella composite insulators:

[0046] 1) Sampling:

[0047] The upper and lower surfaces of the insulator are scrubbed with alcohol-containing absorbent cotton for 5 minutes, so as to ensure that the insoluble contamination has enough time to dissolve in alcohol. Put the absorbent cotton containing dirt into the sample bag and seal it for the equivalent salt density and gray density test.

[0048] 2) Cleaning:

[0049]Take 300ml of deionized water (the specific water consumption can be determined according to the degree of contamination of the absorbent cotton), use 125ml of deionized water to wash the contaminated absorbent cotton for the first time, wring out the absorbent cotton; then use 125ml of deionized water to wash the absorbent cotton for the second time, and put Wring out the absorbent cotton after cleaning. Rinse the container first with 25 ml of deionized water, then rinse the container a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com