Tire fetal-membrane surface character defect detection method based on machine vision

A machine vision and defect detection technology, applied in the field of image processing, can solve problems such as poor accuracy, poor stability, and inability to detect tire membrane character defects, and achieve fast and effective detection, high detection stability, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

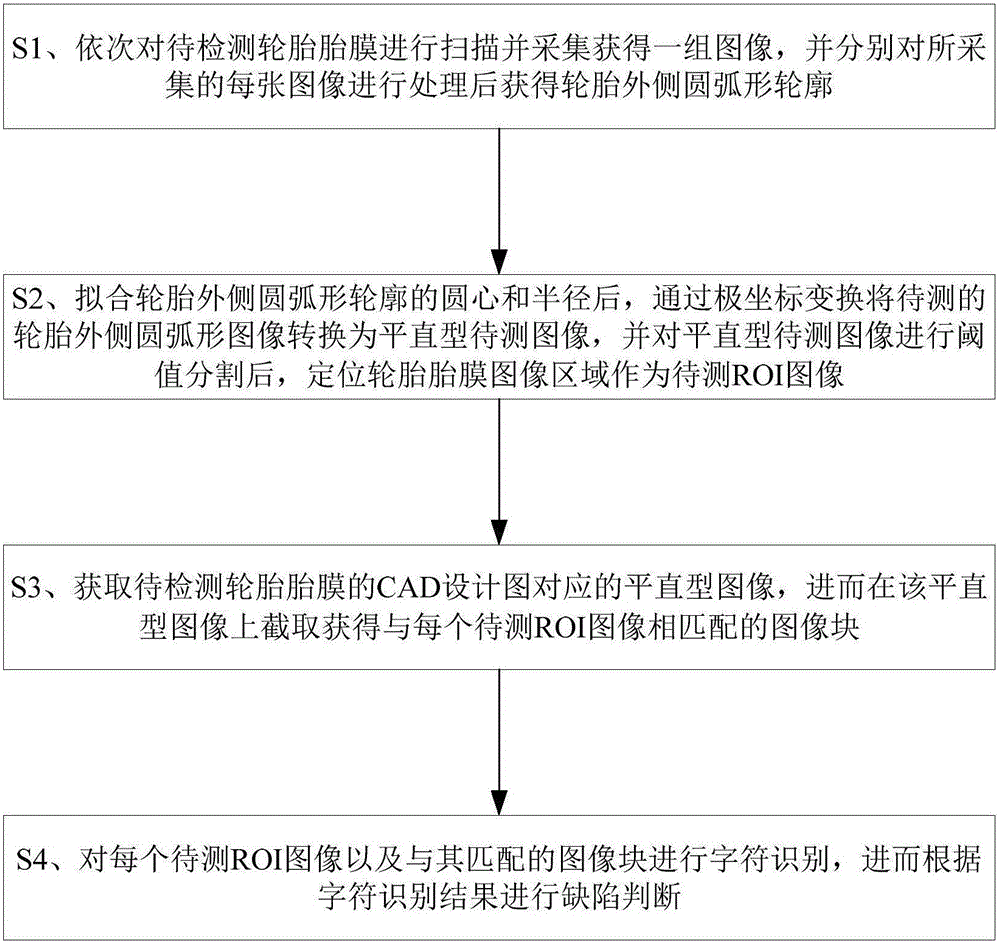

[0055] refer to figure 1 , the invention provides a method for detecting character defects on the surface of tire membranes based on machine vision, comprising:

[0056] S1. Sequentially scan and collect a set of images from the membrane of the tire to be detected, and process each of the collected images to obtain the outer circular arc profile of the tire;

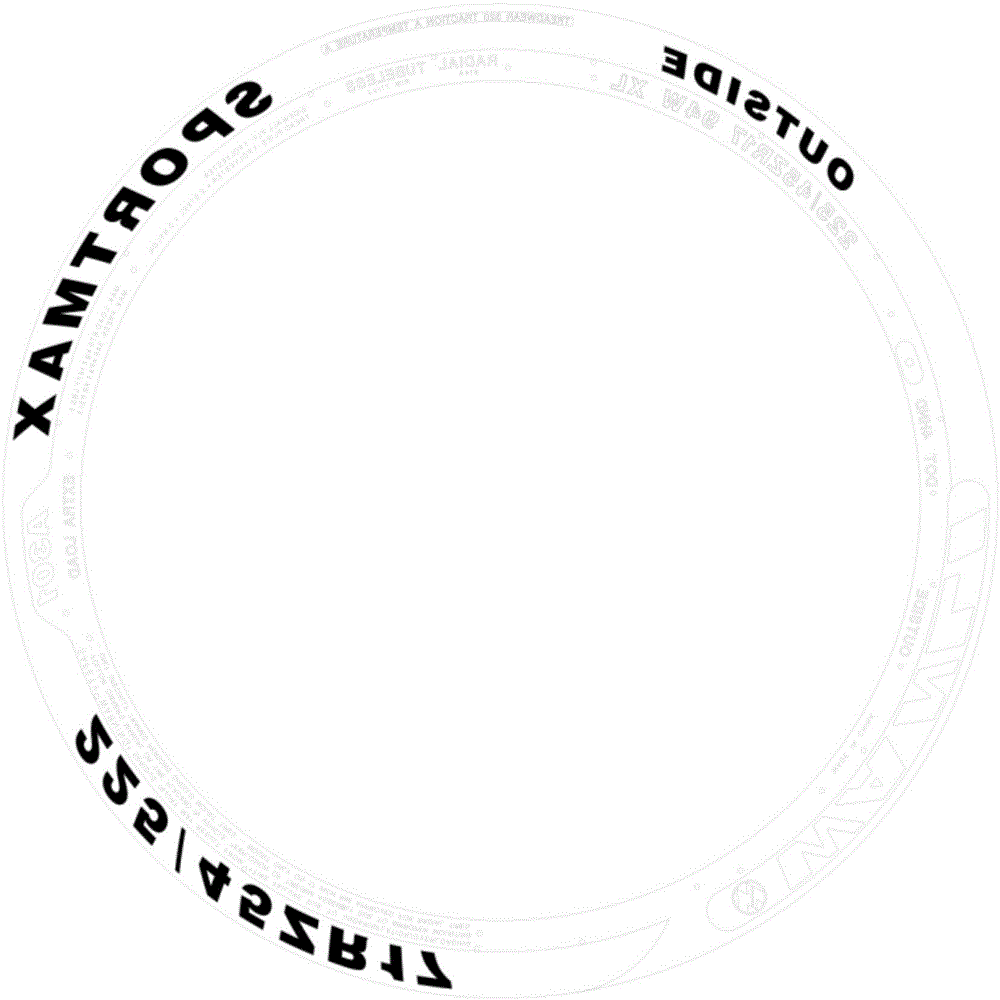

[0057] S2. After fitting the center and radius of the outer circular arc profile of the tire, convert the outer circular arc image of the tire to be tested into a straight image to be tested by polar coordinate transformation, and perform threshold segmentation on the straight image to be tested. After that, locate the tire membrane image area as the ROI image to be tested;

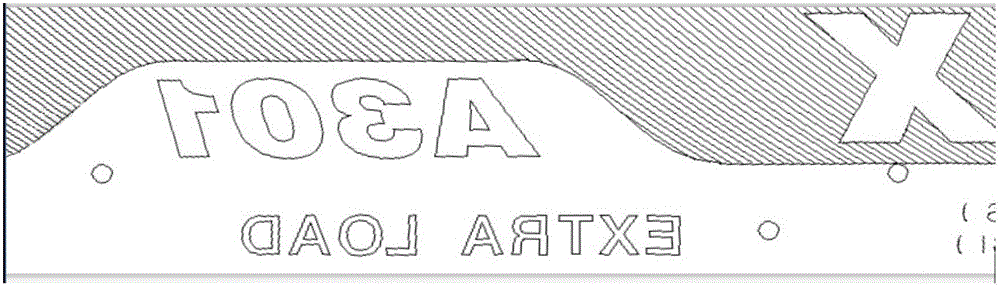

[0058] S3. Obtain a flat image corresponding to the CAD design drawing of the tire membrane to be detected, and then intercept and obtain an image block matching each ROI image to be tested on the flat image;

[0059] S4. Perform character recogni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com