Device for measuring variation of internal temperature during combustion of polymer material

A technology of polymer materials and internal temperature, applied in the field of experimental devices, can solve the problems of lack of experimental devices and methods, and achieve the effects of low manufacturing cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

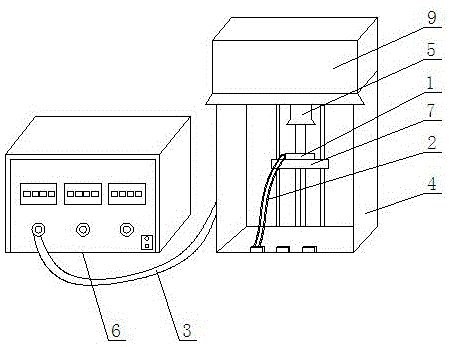

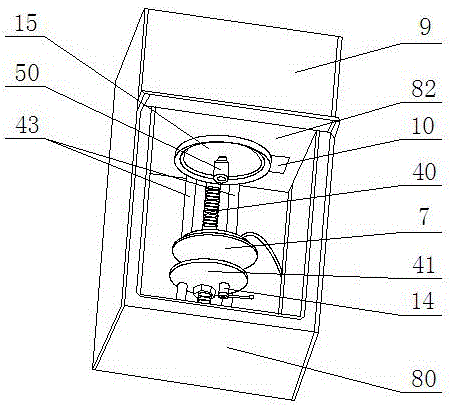

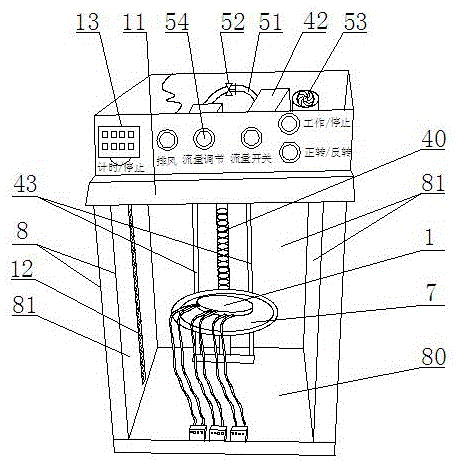

[0021] A device used to measure changes in internal temperature when polymeric materials are burned, such as figure 1 As shown, there is a fixed seat 4 for fixing the polymer material sample 1, a flame injection device 5 capable of spraying flames on the surface of the polymer material sample 1 and a real-time measurement of the polymer material sample 1 at A digital recorder 6 for the internal temperature when burning under the action of a flame. The polymer material sample 1 is embedded with a thermocouple 2 , and the thermocouple 2 is connected to the digital recorder 6 through a thermocouple compensation wire 3 .

[0022] Wherein, in order to adjust the angle between the upper surface of the polymer material sample 1 and the flame ejected from the flame spraying device 5, as figure 1 with figure 2 As shown, the fixed seat 4 is also provided with an angle adjustment device 7 for adjusting the inclination angle of the polymer material sample 1 . And in order to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com