Touch screen display apparatus and manufacturing method thereof

A technology for display devices and touch screens, applied to instruments, electrical digital data processing, and input/output processes of data processing, etc., can solve problems such as fragile screens, increased size of electronic equipment, uneven light transmittance, etc., to reduce assembly Difficulty, reducing the thickness of the screen, and increasing the effect of interactive experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

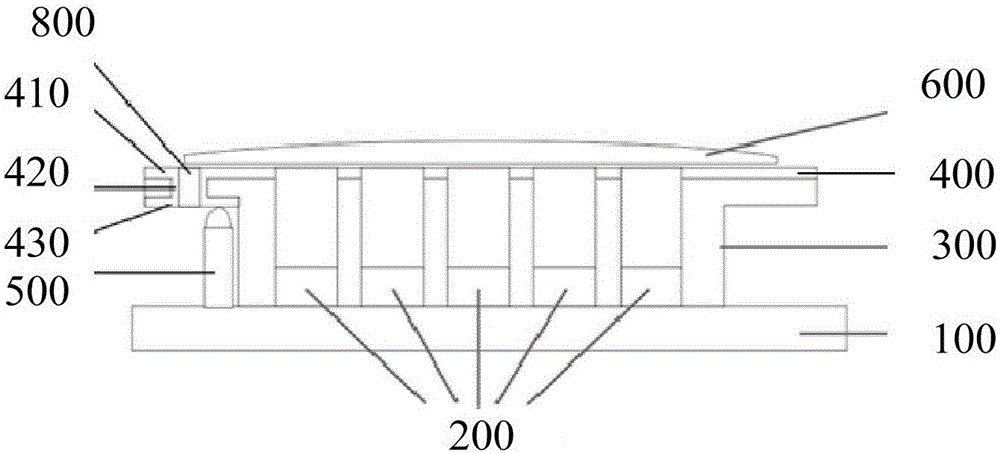

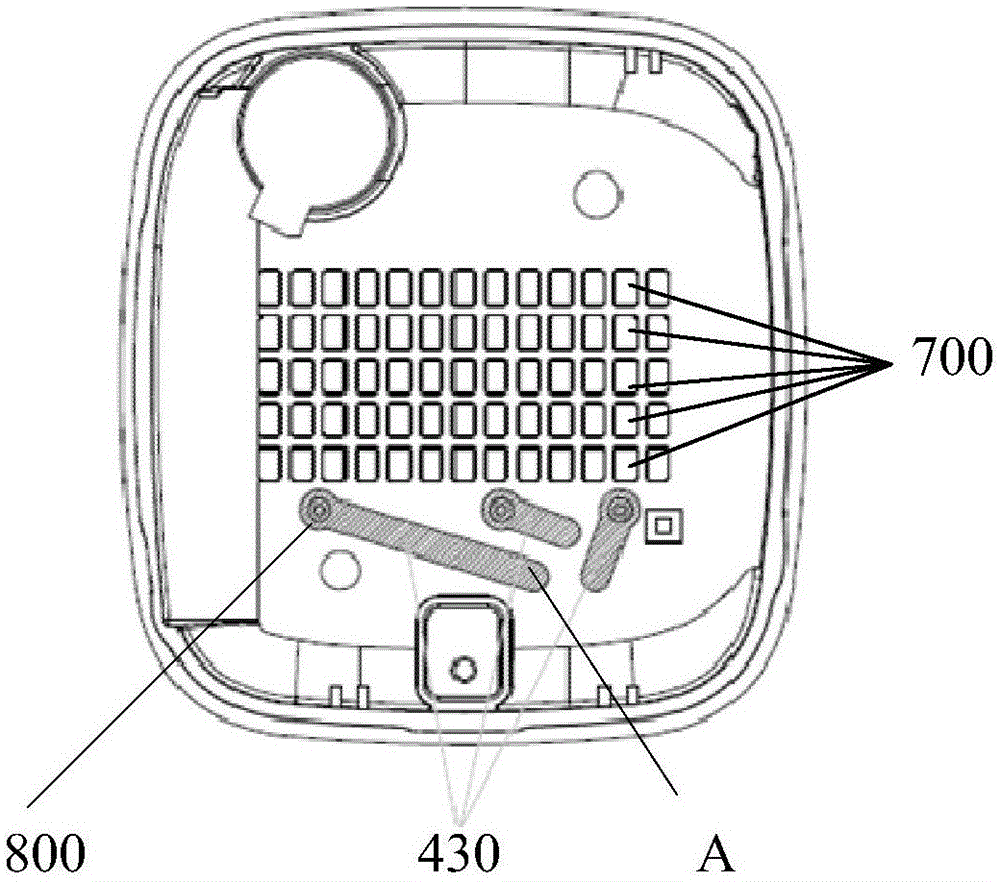

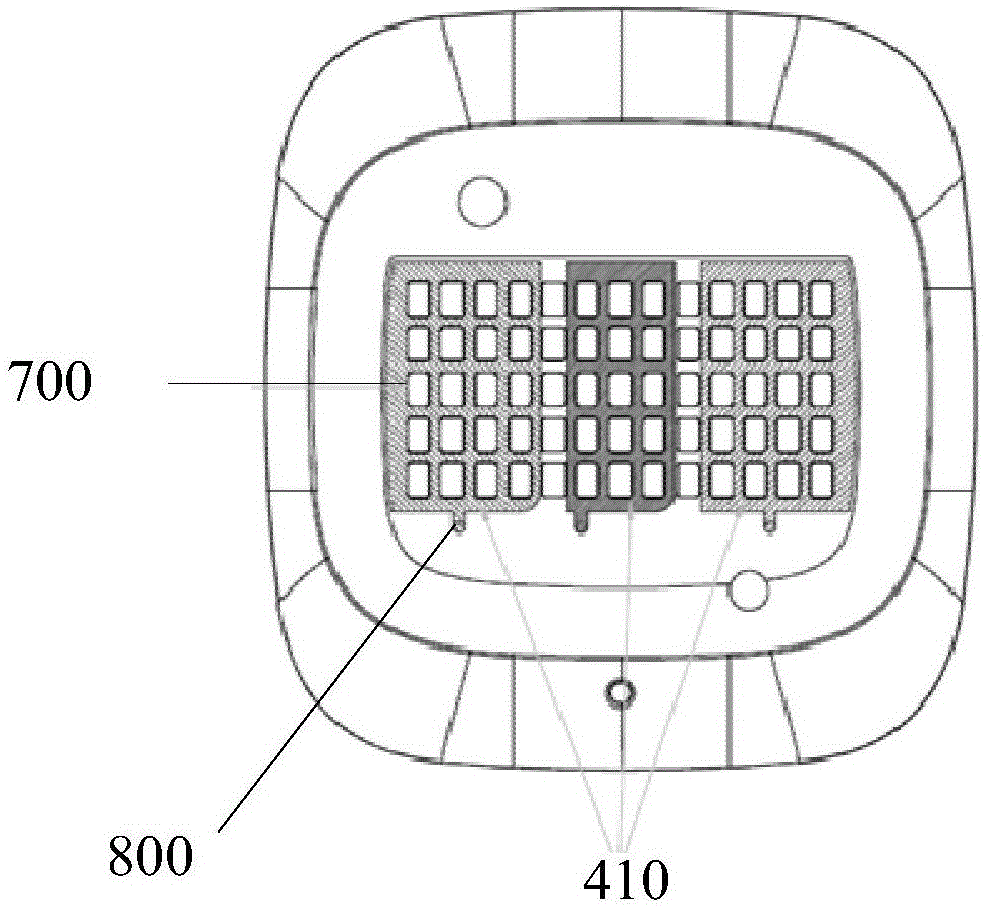

[0058] refer to figure 1 , shows a schematic cross-sectional structure diagram of a touch screen display device according to an embodiment of the present invention, referring to Figure 2a , Figure 2b A schematic diagram of the axonometric structure of a touch screen display device according to an embodiment of the present invention is shown respectively. Specifically, the touch screen display device may include the following units:

[0059] motherboard 100;

[0060] An LED light source 200 located on the main board 100;

[0061] The shading plate 300 located on the upper part of the main board 100; the shading plate 300 is provided with a hole structure at a position corresponding to the LED light source 200;

[0062] Laser engraving the induction metal layer 400 on the surface of the light shielding plate 300; wherein, a metal connection is formed between the induction metal layer and the main board; and

[0063] The touch layer 600 located on the upper part of the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com