Method for reducing damage of substrate material by high-energy particle bombardment

A technology of high-energy ions and substrates, used in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., to reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

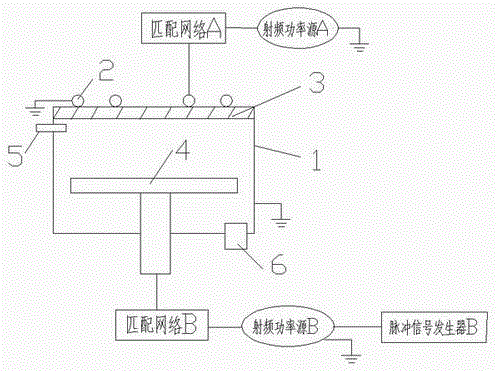

[0021] figure 1 It is a power application method of pulse modulation substrate bias RF power source. Which includes a plasma discharge chamber 1, a discharge coil 2, a quartz window 3, a substrate table 4, an air inlet 5 and an air outlet 6; also includes a radio frequency power source A applied to the discharge coil 2 and placed on the radio frequency The matching network A between the power source A and the discharge coil 2; also includes the RF power source B applied to the substrate stage 4, the RF power source B is connected to the substrate stage 4 through the matching network B, and the RF power source B is modulated by the pulse signal generated by the pulse signal transmitter B.

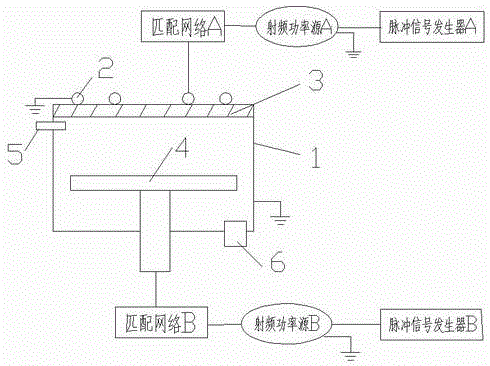

[0022] figure 2 It is another power application method for pulse modulating the substrate bias RF power source. Which includes a plasma discharge chamber 1, a discharge coil 2, a quartz window 3, a substrate table 4, an air inlet 5 and an air outlet 6; also includes a radio frequency pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com