NASICON lithium-ion solid electrolyte synergistically doped with F<-> and Y<3+> ions and preparation method thereof

A solid electrolyte and lithium ion technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., to achieve the effect of weakening the bonding force, improving conductivity, and enhancing migration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

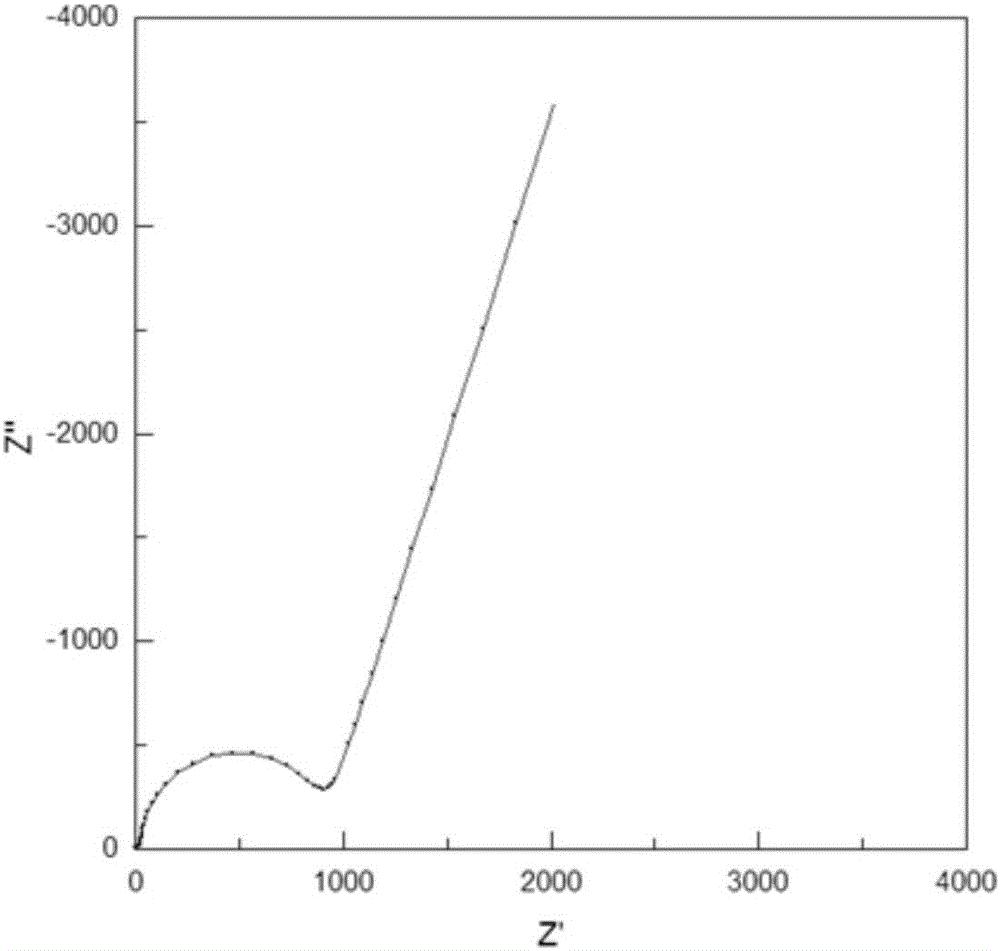

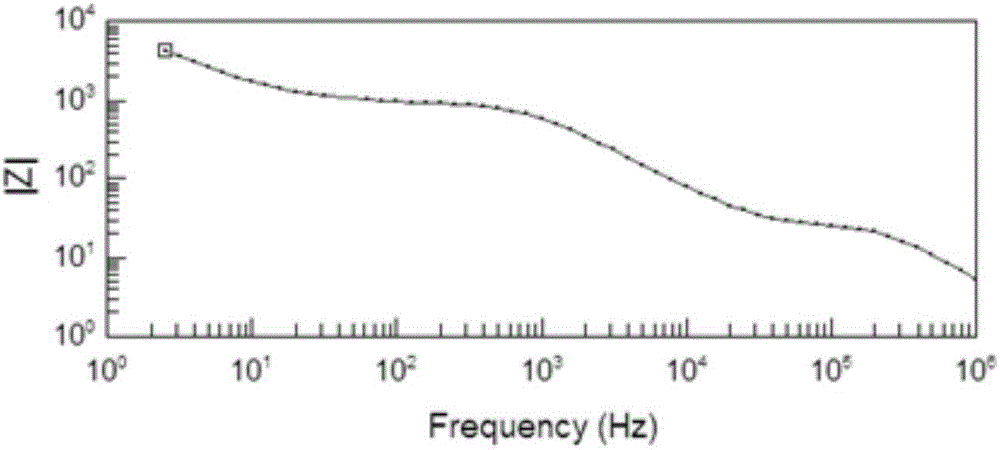

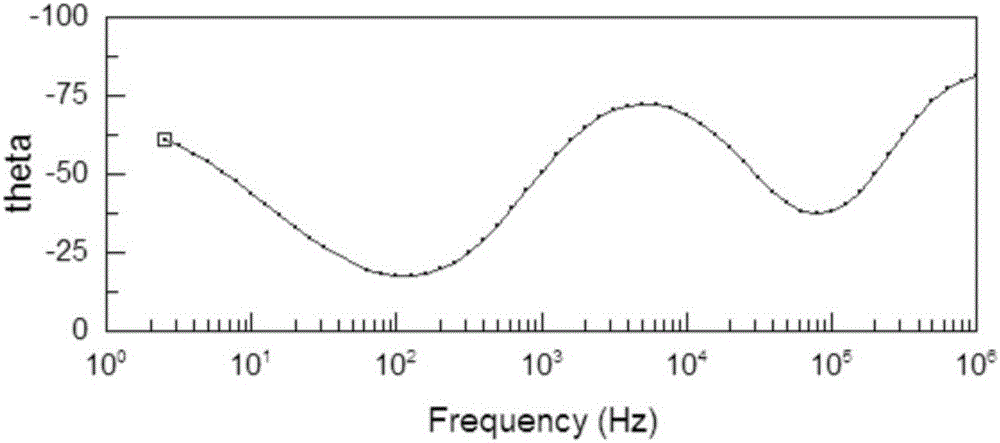

Embodiment 1

[0022] In this example, according to Y(NO 3 ) 3 ·6H 2 O:LiF:ZrOCl 2 ·8H 2 O:(NH 4 ) 2 HPO 4 :LiNO 3 Mix evenly in a ratio of 0.1:0.1:1.9:3.0:1.0 (molar ratio), put it into a 150ml beaker, add 100ml of deionized water, heat and stir on a magnetic heating stirrer at 60°C for 10h, and dry to obtain the precursor , with AR isopropanol as the ball milling solvent, ball milled in a ball mill for 10 hours at a speed of 100 rpm, after the ball milling was finished, it was dried in a vacuum oven at 60°C (vacuum degree at 60Pa) for 5 hours, and after it was taken out, it was placed in an agate mortar Re-grind for 30 minutes, and the ground powder is heated to 900°C at a rate of 3°C / min and kept for 10 hours to make a solid electrolyte powder, whose chemical formula is Li 1.0 Y 0.1 Zr 1.9 P 3 o 11.9 f 0.1. The powder was mixed under a press to form a sheet under a pressure of 200 MPa for 2 minutes, and the sheet was heated to 1210° C. at a rate of 3° C. / min for 10 hours to ...

Embodiment 2

[0024] In this example, according to Y(NO 3 ) 3 ·6H 2 O:LiF:ZrOCl 2 ·8H 2 O:(NH 4 ) 2 HPO 4 :LiNO 3 Mix evenly in a ratio of 0.1:0.2:1.9:3.0:0.9 (molar ratio), put it into a 150ml beaker, add 100ml of deionized water, heat and stir on a magnetic heating stirrer at 80°C for 20h, and dry to obtain the precursor , with AR isopropanol as the ball milling solvent, ball milled for 20 hours at a speed of 200 rpm in a ball mill, dried in a vacuum oven at 80°C (vacuum degree at 100Pa) for 10 hours after ball milling, and put it in an agate mortar after taking it out Re-grind for 60 minutes, and the ground powder is heated at a rate of 5°C / min to 1000°C for 10 hours to make a solid electrolyte powder, whose chemical formula is Li 0.9 Y 0.2 Zr 1.9 P 3 o 11.8 f 0.2 . The powder was mixed under a press to form a sheet under a pressure of 200 MPa for 6 minutes, and the sheet was heated to 1210° C. at a rate of 5° C. / min for 30 hours to make a lithium ion solid electrolyte shee...

Embodiment 3

[0026] In this example, Y(NO 3 ) 3 ·6H 2 O:LiF:ZrOCl 2 ·8H 2 O:(NH 4 ) 2 HPO 4 :LiNO 3 Mix evenly in a ratio of 0.2:0.1:1.8:3.0:1.1 (molar ratio), put it into a 150ml beaker, add 100ml of deionized water, heat and stir on a magnetic heating stirrer at 70°C for 15h, and dry to obtain the precursor , with AR isopropanol as the ball milling solvent, ball milled in a ball mill for 25 hours at a speed of 300 rpm, dried in a vacuum oven at 70°C (vacuum degree at 90Pa) for 15 hours after ball milling, and put it in an agate mortar after taking it out Re-grind for 50 minutes, and the ground powder is heated to 1150°C at a rate of 5°C / min and kept for 20 hours to make a solid electrolyte powder, whose chemical formula is Li 1.1 Y 0.2 Zr 1.8 P 3 o 11.9 f 0.1 . The powder was mixed under a press to form a sheet under a pressure of 300 MPa for 4 minutes, and the sheet was heated to 1210° C. at a rate of 5° C. / min for 30 hours to make a lithium-ion solid electrolyte sheet. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com