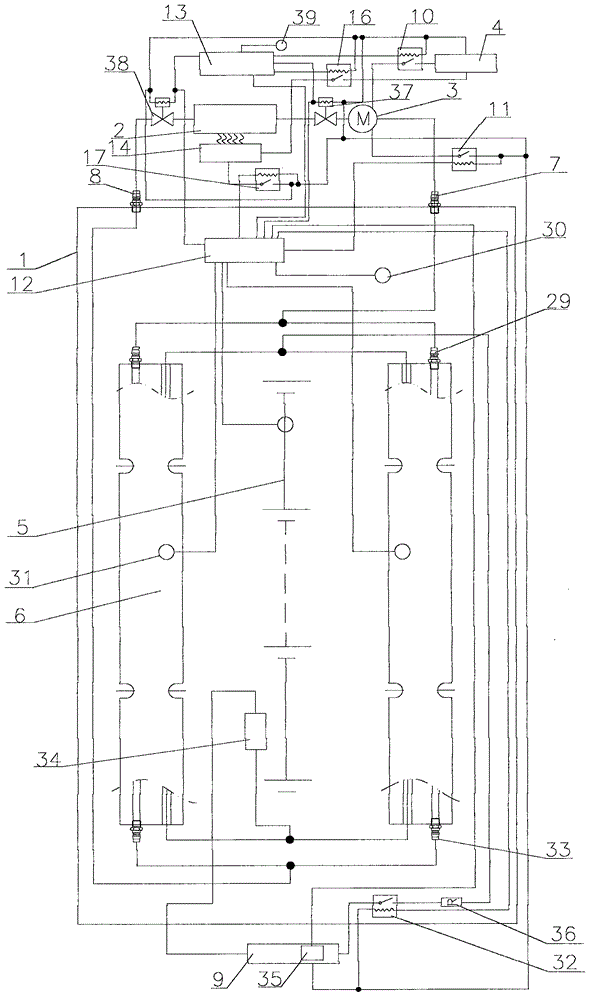

Heat balance management device for power battery pack and management method of heat balance management device

A power battery pack and management device technology, applied in secondary batteries, battery temperature control, secondary battery repair/maintenance, etc., can solve problems affecting battery life, safety hazards, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] When the electric vehicle is charging and the outdoor air temperature is too low, the temperature sensor 31 detects the temperature inside the battery box 1, and when the temperature inside the battery box 1 is 5°C, the vehicle charging heating method is adopted:

[0084] Step 1: The temperature sensor 31 feeds back the detected temperature data inside the battery case 1 to the battery management system 12;

[0085] Step 2: Process the temperature data fed back to the battery management system 12 as described in step 1, and check that the communication module 35 of the charging device 9 has no fault signal fed back to the battery management system 12. At this time, the charging device 9 is operating normally;

[0086] Step 3: When the charging device 9 described in Step 2 operates normally, the battery management system 12 closes the switch of the fifth relay switch 32 by controlling the coil in the fifth relay switch 32;

[0087] Step 4: After the switch of the fifth r...

Embodiment 2

[0092] When the electric vehicle is charging and the outdoor air temperature is too low, the temperature sensor 31 detects the temperature inside the battery box 1, and when the temperature inside the battery box 1 is 3°C, the vehicle charging heating method is adopted:

[0093] Step 1: The temperature sensor 31 feeds back the detected temperature data inside the battery case 1 to the battery management system 12;

[0094] Step 2: Process the temperature data fed back to the battery management system 12 as described in step 1, and check that the communication module 35 of the charging device 9 has no fault signal fed back to the battery management system 12. At this time, the charging device 9 is operating normally;

[0095] Step 3: When the charging device 9 described in Step 2 operates normally, the battery management system 12 closes the switch of the fifth relay switch 32 by controlling the coil in the fifth relay switch 32;

[0096] Step 4: After the switch of the fifth r...

Embodiment 3

[0101]When the electric vehicle runs for a long time, the temperature sensor 31 detects the temperature inside the battery box 1, and when the temperature inside the battery box 1 is 40°C, the cooling method of the vehicle running is adopted:

[0102] Step 1: The temperature sensor 31 feeds back the detected temperature data inside the battery case 1 to the battery management system 12;

[0103] Step 2: Process the temperature data fed back to the battery management system 12 in step 1 and feed it back to the vehicle controller 13. The vehicle controller 13 controls the coil of the first normally closed electromagnetic valve 37 and the second normally closed solenoid valve 37. The coil of the electromagnetic valve 38 opens the first normally closed electromagnetic valve 37 and the second normally closed electromagnetic valve 38, and then the vehicle controller 13 closes the switch of the first relay switch 10 by controlling the coil of the first relay switch 10;

[0104] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com