Steel plate with excellent hydrogen-induced cracking resistance and toughness of the weld heat affected zone, and steel tube for use as line pipe

A welding heat-affected and hydrogen-induced crack resistance technology, applied in the field of pipeline steel pipes, can solve the problems of toughness deterioration and brittle fracture, and achieve the effect of excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

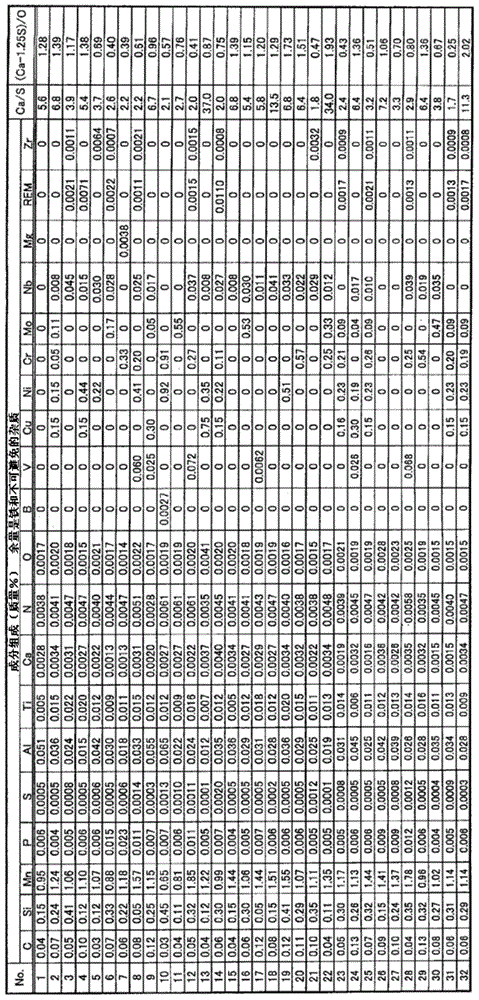

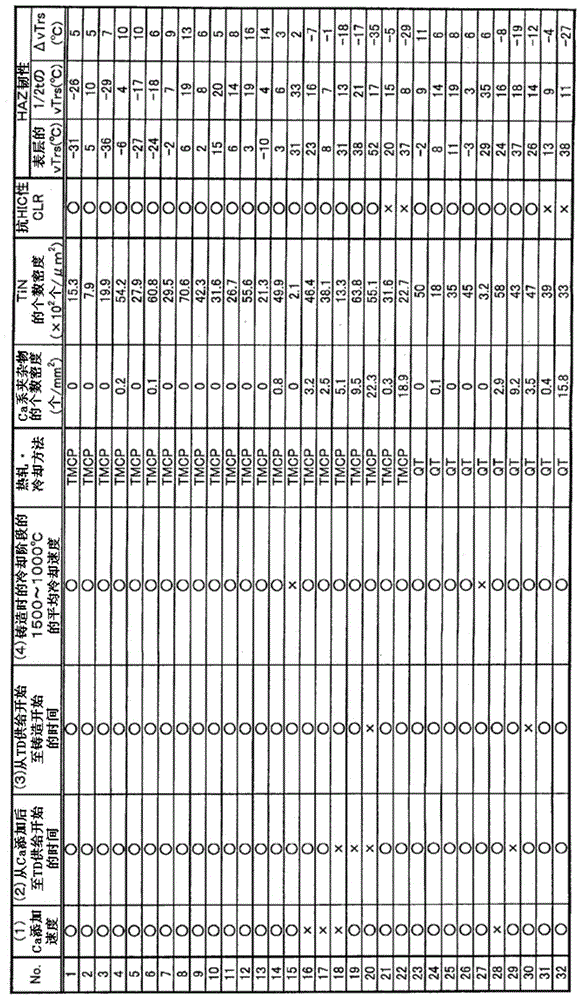

[0107] Hereinafter, the present invention will be described in more detail by way of examples, but it goes without saying that the present invention is not limited to the following examples, and can of course be appropriately modified and implemented within the scope that can meet the foregoing and the following principles, and these are all included in the present invention. range of technologies.

[0108] The steel of the composition shown in Table 1 was melted, and a slab (slab) having a thickness of 280 mm was obtained by the following Ca addition method and casting method. Table 2 shows the conditions for adding Ca to continuous casting in the manufacturing process. That is, in the Ca addition step after LF and RH treatment, when the addition rate of Ca is set to be 0.002 kg / min·t to 0.020 kg / min·t, the column of “(1) Ca addition rate” in Table 2 It is "○", and other cases are "x". In addition, when the time from the addition of Ca to the start of supply of molten steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com