Manufacturing method for vaccinium bracteatum leaf tea

A technology of black rice leaves and leaf bags, which is applied in the field of preparation of blood pressure lowering black rice leaf tea, to achieve the effect of light yellowish green color, sweet aftertaste, and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

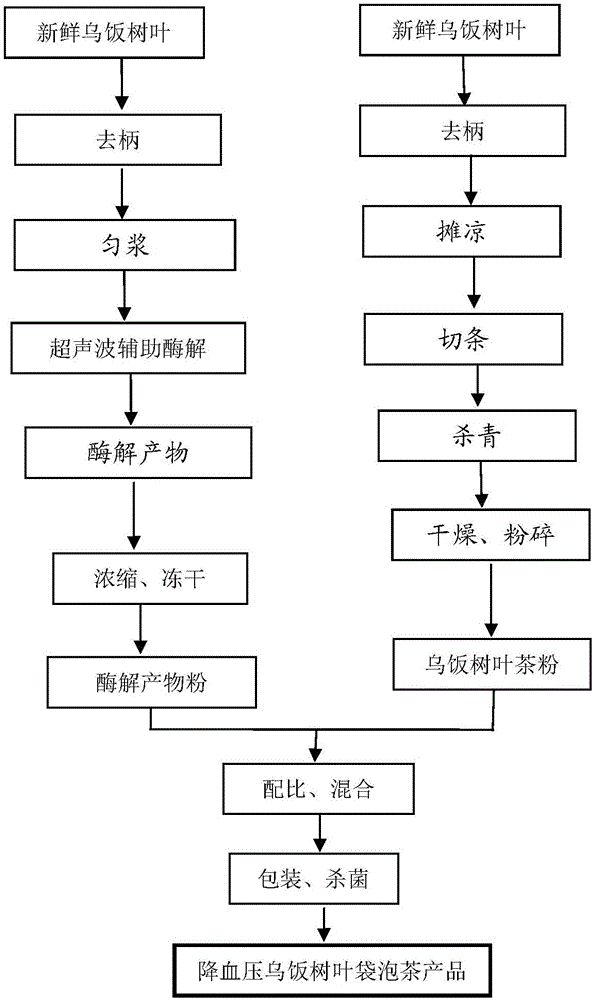

Method used

Image

Examples

Embodiment 1

[0024] (1) Clean up after removing the stalk of fresh black rice leaves, after beating, be made into a suspension of 5% (w / v, g / L) with distilled water, place in the 40kHz ultrasonic washing tank, the water bath temperature is set to 40°C, when the temperature of the water bath reaches the set temperature, at natural pH, add neutral protease (alias serrapeptase, also known as serrapeptase. The English name is: dispase, or neutralproteinase, produced by Bacillus subtilis through deep Extracted after fermentation, it belongs to a kind of endonuclease), stir evenly and turn on the ultrasonic wave, the ultrasonic power is 90W, ultrasonic assisted enzymolysis for 30 minutes and then centrifuged, the enzymatic hydrolyzate is concentrated, freeze-dried, and the enzymatic hydrolysis of the leaf protein of black rice leaf is obtained product, spare

[0025] (2) Remove the stalks from fresh black rice leaves, cool them at room temperature for 5 hours, cut them into 1cm-wide strips, boil...

Embodiment 2

[0028] (1) Clean up after removing the stalk of fresh black rice leaves, after beating, be made into the suspension of 7.5% (w / v, g / L) with distilled water, place in the 40kHz ultrasonic washing tank, the water bath temperature is set to 45°C, when the temperature of the water bath reaches the set temperature, under the natural pH, add neutral protease according to the enzyme amount of 3000U / g, stir evenly and turn on the ultrasonic wave, the ultrasonic power is 105W, ultrasonic assisted enzymatic hydrolysis for 40 minutes, centrifugation, enzymatic hydrolysis After the product is concentrated, it is freeze-dried to obtain the enzymatic hydrolyzate of the leaf proteolytic product of the black rice tree, which is ready for use;

[0029] (2) Remove the stalks from fresh black rice leaves, spread them in the air at room temperature for 6 hours, cut them into 2cm-wide strips, boil them for 75 seconds, dry them in the shade at room temperature (11 hours), dry them at 55°C, and crush...

Embodiment 3

[0032] (1) Clean up after removing the stalk of fresh black rice leaves, after beating, be made into a suspension of 10% (w / v, g / L) with distilled water, place in the 40kHz ultrasonic washing tank, the water bath temperature is set to 50°C, when the temperature of the water bath reaches the set temperature, at natural pH, add neutral protease according to the enzyme amount of 3500U / g, stir evenly and turn on the ultrasonic wave, the ultrasonic power is 120W, ultrasonic assisted enzymatic hydrolysis for 50 minutes, centrifugation, enzymatic hydrolysis After the product is concentrated, it is freeze-dried to obtain the enzymatic hydrolyzate of the leaf proteolytic product of the black rice tree, which is ready for use;

[0033] (2) Remove the stalks from fresh black rice leaves, cool them at room temperature for 7 hours, cut them into 3cm wide strips, boil them for 90 seconds, dry them in the shade at room temperature (12 hours), dry them at 60°C, and crush them to get black rice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com