Ready-to-eat spicy and hot dried egg production process

A production process, egg drying technology, applied in the field of food processing, to achieve the effect of enhancing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

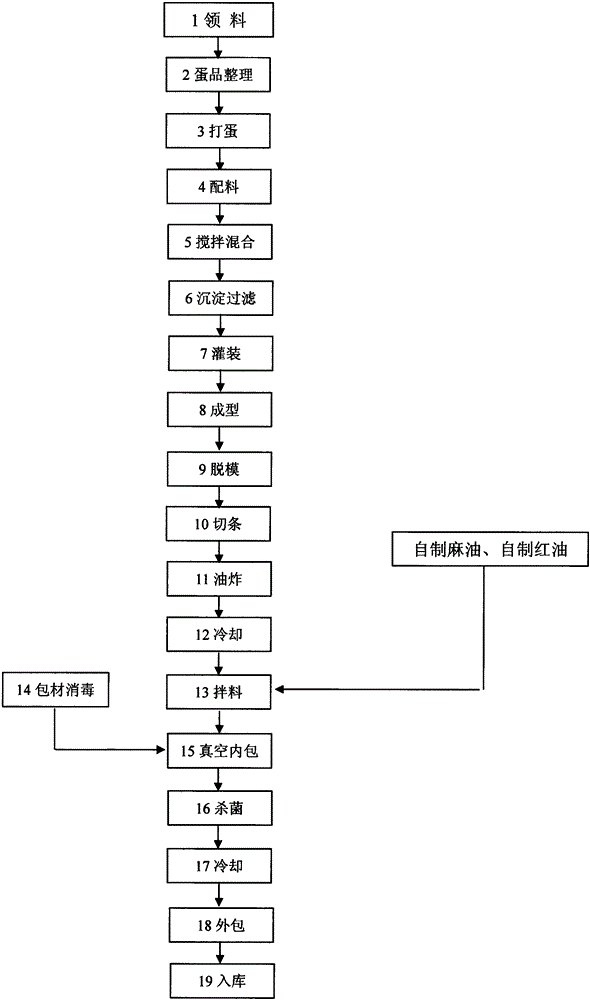

[0017] A production process of ready-to-eat spicy dried eggs, which is composed of ingredients and ingredients; the ingredients are composed of raw materials and self-made brine, and the raw materials in the ingredients include 20,000g of egg liquid, 300-500g of homemade brine, and 50,100g of soy sauce , Edible salt 20-100g, yeast extract 1-10g, white sugar 20-100g, chicken powder 10-50g.

[0018] The self-made brine in the ingredients includes 1000g of water, 10-50g of fresh ginger, 0.1-2.0g of grass fruit, 0.1-2.0g of star anise, 0.1-2.0g of bay leaf, 0.1-2.0g of cinnamon bark, 0.1-2.0g of Chinese prickly ash, dried 0.1-2.0g pepper, 0.1-2.0g cumin, 0.1-2.0g licorice.

[0019] The seasoning formula includes 1000g of dried egg, 10-100g of oil, 10-50g of white sugar, 1-10g of yeast extract, 0.1-3g of edible salt, 0.1-3g of edible essence, 10-50g of homemade sesame oil, 10-50g of homemade red Oil 10-50g, Cordyceps flower 5-50g.

[0020] The oil formula includes 5000-10000g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com