Tobacco sheet and production method thereof

A tobacco sheet and production method technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of waste of tobacco stalks and bottom tobacco, shortage of raw materials for tobacco sheet production, and environmental pollution, so as to improve quality and solve the shortage of production raw materials , The effect of small investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

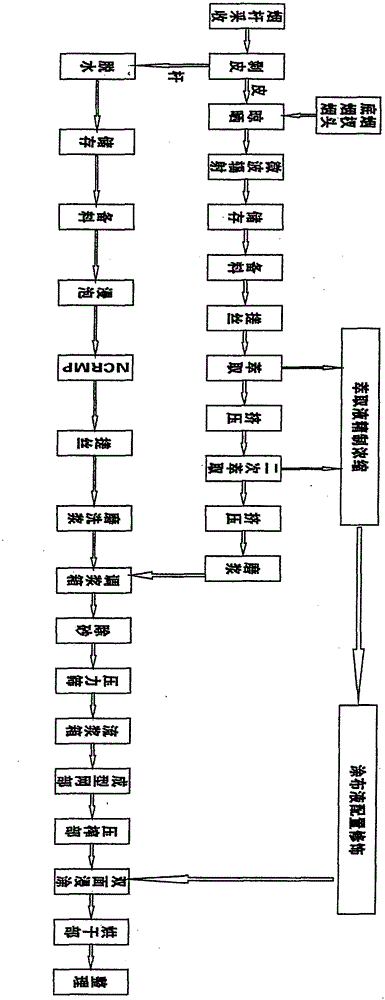

[0038] A tobacco sheet and its production method, its technical scheme is shown in the accompanying drawings, and includes the following steps:

[0039] 1. Harvesting of tobacco stalks: Harvesting of fresh tobacco stalks at a distance of 80mm from the ground;

[0040] 2. Peeling: fresh tobacco stalks are rotary cut and peeled to a thickness of 1.2mm, and the stems and skins are separated;

[0041] 3. Tobacco skins are dried in the air: the tobacco skins are dried to a moisture content of 18%;

[0042] 4. Microwave radiation: microwave power 1000W, radiation time 2min;

[0043] 5. Tobacco skin preparation: crush, wash and remove impurities from the tobacco skin, the length of the tobacco skin is 30-50mm, and the moisture content is 26%;

[0044] 6. Tobacco skin NCRMP treatment: put the tobacco skin into the NCRMP tank, add saturated steam at a pressure of 1.2mpa and steam for 4 minutes; then add compressed air to a pressure of 2.0mpa and keep the pressure for 1 minute before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com