Uniform-temperature pot body and manufacturing method thereof

A pot body, warming technology, applied in heating devices, cooking utensils, household utensils, etc., can solve the problems of affecting the color, taste and nutrition of food, slow heating at the top, uneven heating, etc. The effect of gelatinization and reducing harmful oil fumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

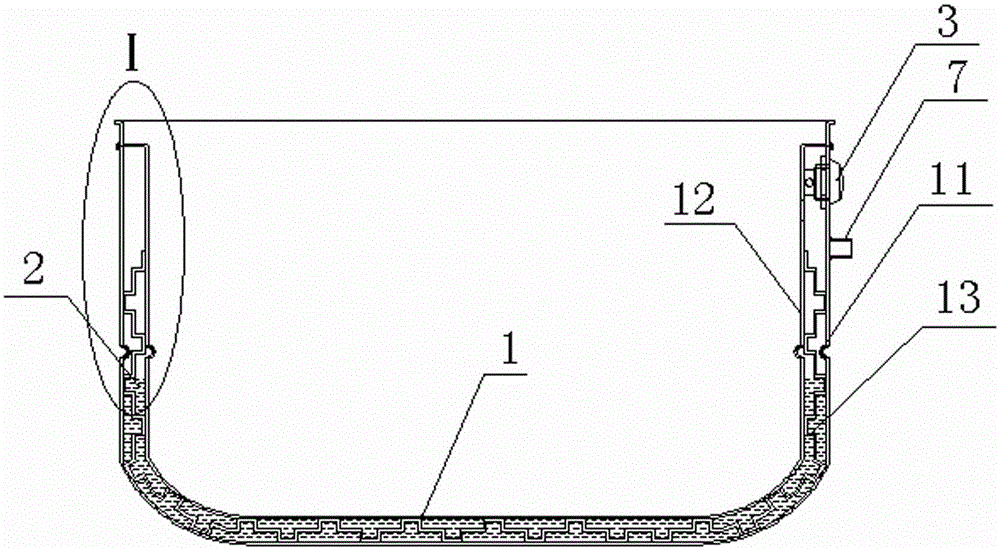

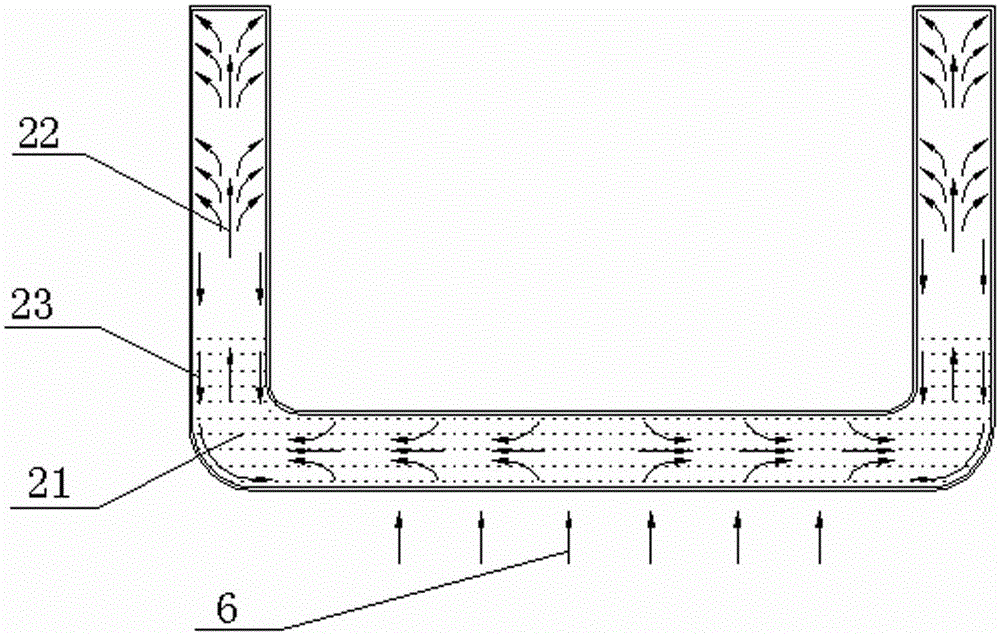

[0031] Such as Figure 1~4 As shown, a uniform temperature pot body includes a uniform temperature plate 1, a heat exchange medium 2 and a safety valve 3. The temperature uniform plate 1 includes an outer wall 11 and an inner wall 12, and the outer wall 11 and the inner wall 12 are connected by a seal Zone 4 is connected to form a heat pipe type airtight cavity, the heat exchange working medium 2 is placed in the airtight cavity, the safety valve 3 is installed at the opening end of the airtight cavity, and the safety valve on the outer wall 11 is A liquid filling port 7 is installed on one side of 3, and the vapor chamber 1 can be processed into pots of various shapes. The whole pot body heats up rapidly to reach the same temperature. The safety valve 3 is used to protect the pressure in the airtight cavity. When the vacuum pressure in the airtight cavity exceeds the set safety pressure during use, the pressure can be released through the safety valve 3, effectively ensuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com