Fixed-wing aircraft realizing vertical take-off and landing

A vertical take-off and landing, fixed-wing technology, applied in the field of aircraft, can solve problems such as reducing aircraft performance, pressure differential resistance loss, increasing costs, etc., to reduce manufacturing costs, reduce difficulty and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

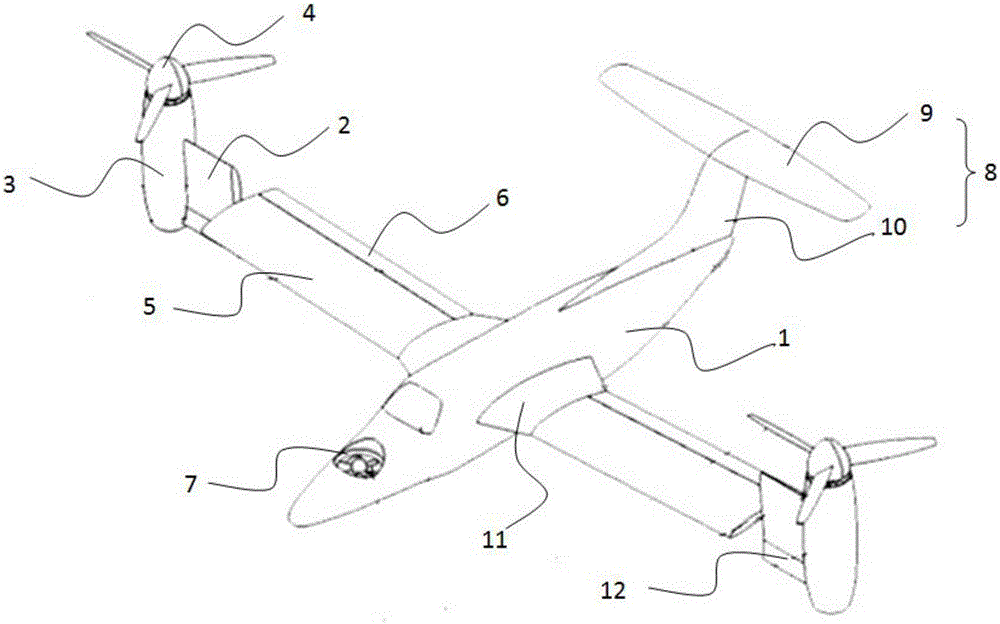

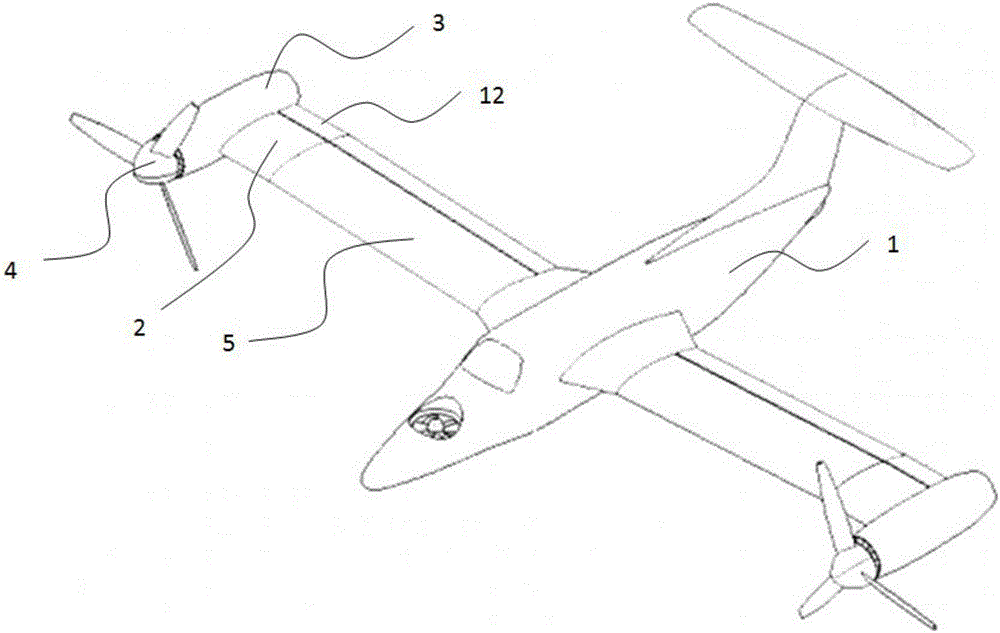

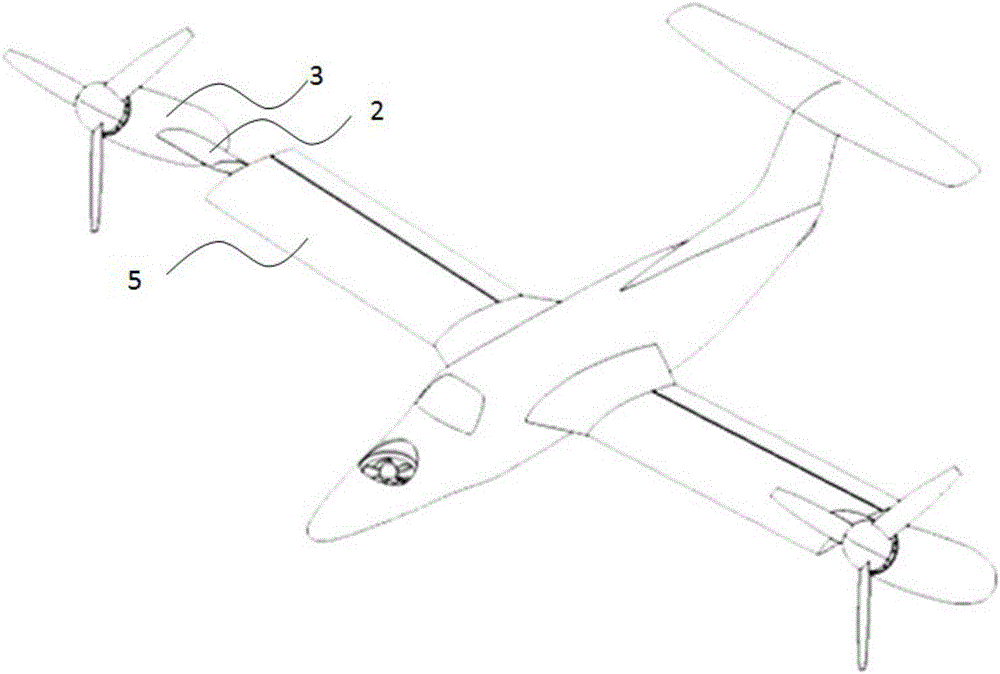

[0027] For the vertical take-off and landing fixed-wing aircraft described in this embodiment, see Figure 1-3 , it comprises fuselage 1, empennage 8 and 2 power units with tilting mechanism, described power unit with tilting mechanism comprises fixed-pitch propeller 4, engine (not shown in the figure), slipstream rudder 12. Wing, tilting wing 2, engine compartment 3 and steering gear (not shown in the figure), the engine is installed in the engine compartment 3, the fixed-pitch propeller 4 is connected to the output shaft of the engine, and one end of the tilting wing 2 is fixed Connected to the engine compartment 3, the other end is rotatably connected to the wing, the slipstream rudder 12 is movably connected to the tilting wing 2, the steering gear drives the slipstream rudder 12, and the power with the tilting mechanism The device is symmetrically arranged on both sides of the fuselage 1, and is connected to the fuselage 1 through a connecting part, and is arranged horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com