The preparation method of bedaquiline

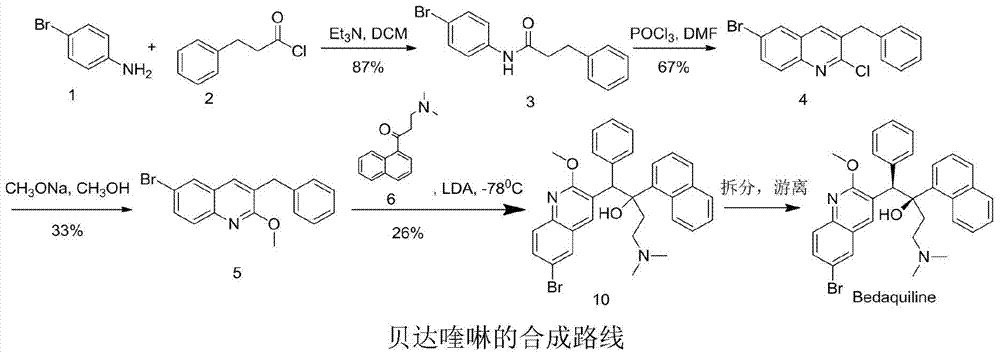

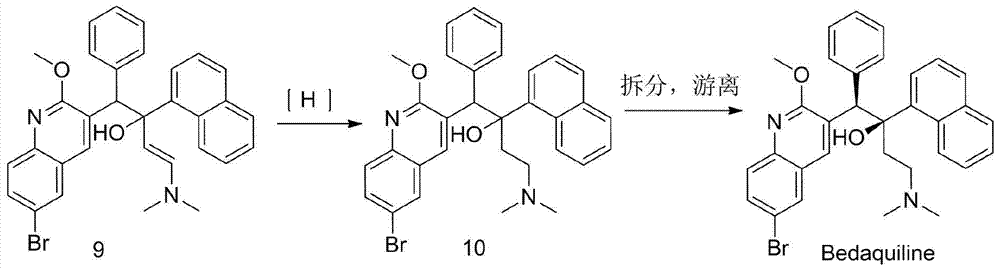

A technology of bedaquiline and its compound, which is applied in the field of drugs for the treatment of multidrug-resistant tuberculosis, can solve the problems of low purity of bedaquiline racemate, incomplete conversion of raw materials, and affecting the efficiency of resolution, etc., and achieves the goal of preparing Low cost, large positive progress effect and practical application value, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

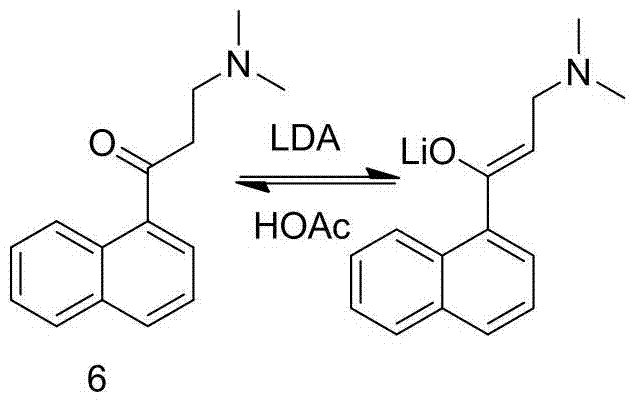

[0042] Preparation of 3-dimethylamino-2-(1-naphthyl)-prop-2-en-1-one (compound 8)

[0043] 1-Naphthyl ethyl ketone (170.0g, 1.0mol) was added to DMF-DMA (178.0g, 1.5mol) at room temperature, heated to 120°C, after 24h, cooled to room temperature, added 200ml of toluene to dilute, and then the solvent Evaporate to dryness under reduced pressure at 55°C, dilute the residue by adding 200ml of toluene, and evaporate to dryness under reduced pressure at 55°C to obtain 230.1g of yellow oil, with a crude yield of 102% and a purity of 98.5% by HPLC, which can be directly used in the next reaction .

[0044] 1 H-NMR (CDCl 3 )δ: 2.93-3.14 (m, 6H); 5.73 (d, 1H, J = 12.4Hz); 7.38-7.49 (m, 2H); 7.82 (d, 1H, J = 12.4Hz); 7.78 (m, 1H ),8.14-3.18(m,2H),8.29(d,2H,J=8.4Hz),9.45(d,2H,J=8.8Hz).ESI-MS(m / z)=226.2[M+H] +

Embodiment 2

[0046] Preparation of 3-dimethylamino-2-(1-naphthyl)-prop-2-en-1-one (compound 8)

[0047] 1-Naphthylethanone (150.0g, 0.88mol) was added to DMF-DMA (57.5g, 1.5mol) at room temperature, heated to 90°C, after 24h, cooled to room temperature, added 200ml of toluene to dilute, and then the solvent Evaporate to dryness under reduced pressure at 55°C, add 200ml of toluene to the residue to dilute, and evaporate to dryness under reduced pressure at 55°C to obtain 202.5g of yellow oil, crude yield 102%, HPLC purity 98.8%. ESI-MS(m / z)=226.2[M+H] +

Embodiment 3

[0049] Preparation of 3-dimethylamino-2-(1-naphthyl)-prop-2-en-1-one (compound 8)

[0050] 1-Naphthyl ethyl ketone (250.0g, 1.47mol) was added to DMF-DMA (262.5g, 2.20mol) at room temperature, heated to 90°C, after 48h, cooled to room temperature, added 200ml of toluene to dilute, and then the solvent Evaporate to dryness under reduced pressure at 55°C, add 200ml of toluene to the residue to dilute, and evaporate to dryness under reduced pressure at 55°C to obtain 334.2g of yellow oil with a crude yield of 101% and an HPLC purity of 98.2%. ESI-MS(m / z)=226.2[M+H] +

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com