High-efficiency sound-muffling three-level air filtration system

A technology of air filtration and high-efficiency filter, which is applied in the charging system, the air inlet of the turbine/propulsion device, combustion air/combustion-air treatment, etc., and can solve the problems of poor noise reduction and sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

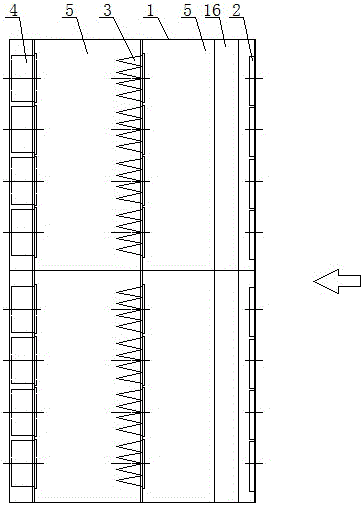

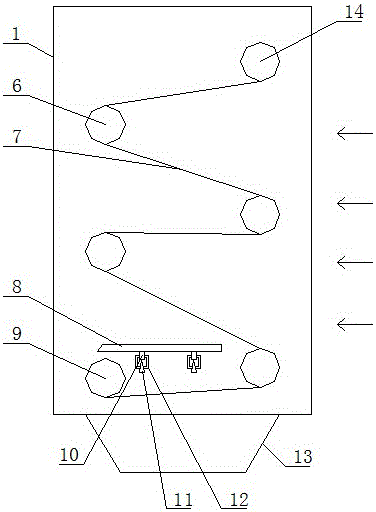

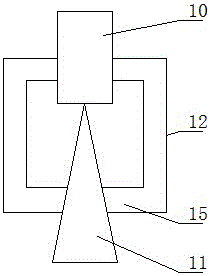

[0062] The high-efficiency noise reduction three-stage air filtration system of the present embodiment includes a filter room, and a coarse-effect filter, a medium-effect filter and a high-efficiency filter are arranged in the filter room, and the coarse-effect filter and the medium-effect filter There is an inspection channel between them, and an inspection channel is provided between the medium-efficiency filter and the high-efficiency filter. The medium-efficiency filter includes a top drive drum installed in the filter room, a bottom drive drum and The driven roller between the bottom driving roller and the driven roller is installed alternately left and right in the filter room; the top driving roller, driven roller and bottom driving roller are covered with a filter layer, and are located at the bottom of the filter room The top of the filter layer between the driven drum and the bottom driving drum is equipped with a blowing system; Line and the center line of the blowb...

Embodiment 2

[0064]The three-stage air filtration system of high-efficiency noise reduction in this embodiment includes a filter room, and a coarse-effect filter, a medium-effect filter and a high-efficiency filter are arranged in the filter room, and the coarse-effect filter and the medium-effect filter There is an inspection channel between them, and an inspection channel is provided between the medium-efficiency filter and the high-efficiency filter. The medium-efficiency filter includes a top drive drum installed in the filter room, a bottom drive drum and a drive drum installed on the top. The driven roller between the bottom driving roller and the driven roller is installed alternately left and right in the filter room; the top driving roller, driven roller and bottom driving roller are covered with a filter layer, and are located at the bottom of the filter room An injection system is provided above the filter layer between the driven drum and the bottom driving drum; the injection s...

Embodiment 3

[0066] The three-stage air filtration system of high-efficiency noise reduction in this embodiment includes a filter room, and a coarse-effect filter, a medium-effect filter and a high-efficiency filter are arranged in the filter room, and the coarse-effect filter and the medium-effect filter There is an inspection channel between them, and an inspection channel is provided between the medium-efficiency filter and the high-efficiency filter. The medium-efficiency filter includes a top drive drum installed in the filter room, a bottom drive drum and a drive drum installed on the top. The driven roller between the bottom driving roller and the driven roller is installed alternately left and right in the filter room; the top driving roller, driven roller and bottom driving roller are covered with a filter layer, and are located at the bottom of the filter room An injection system is provided above the filter layer between the driven drum and the bottom driving drum; the injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com