A model stage of a centrifugal compressor

A technology of centrifugal compressor, model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

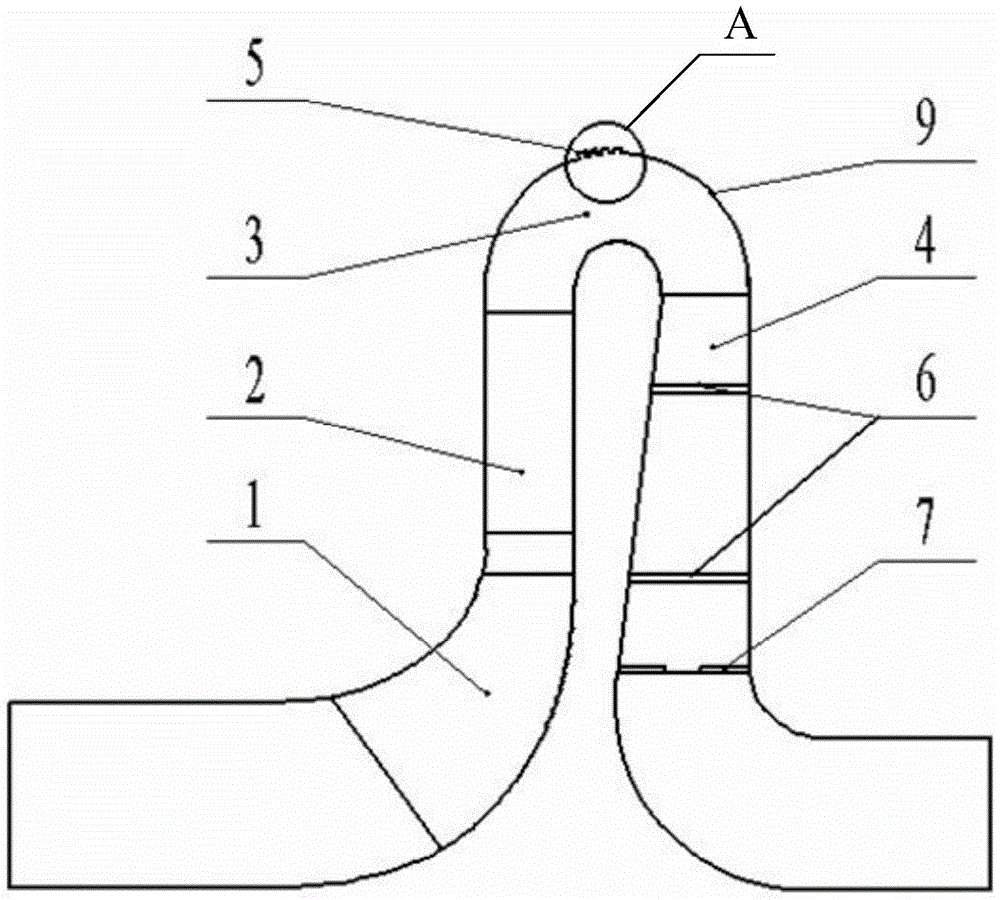

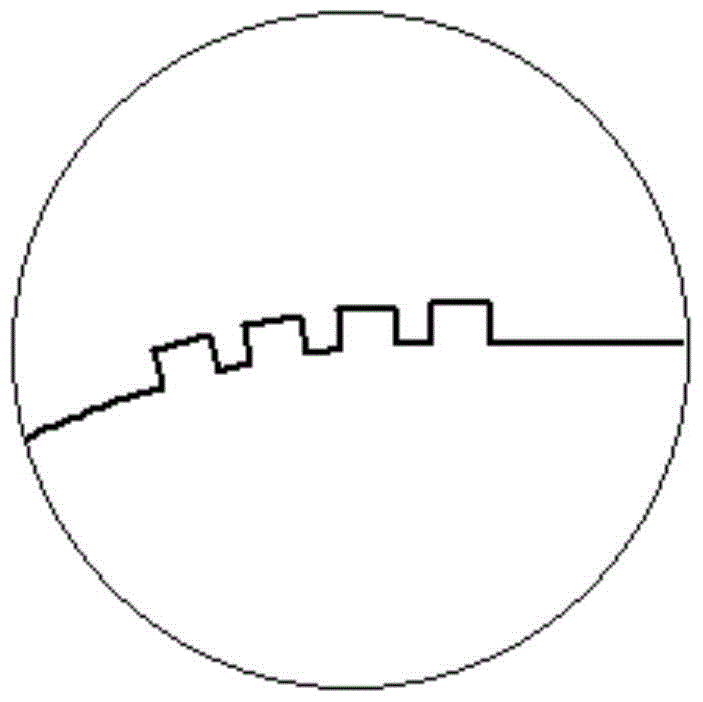

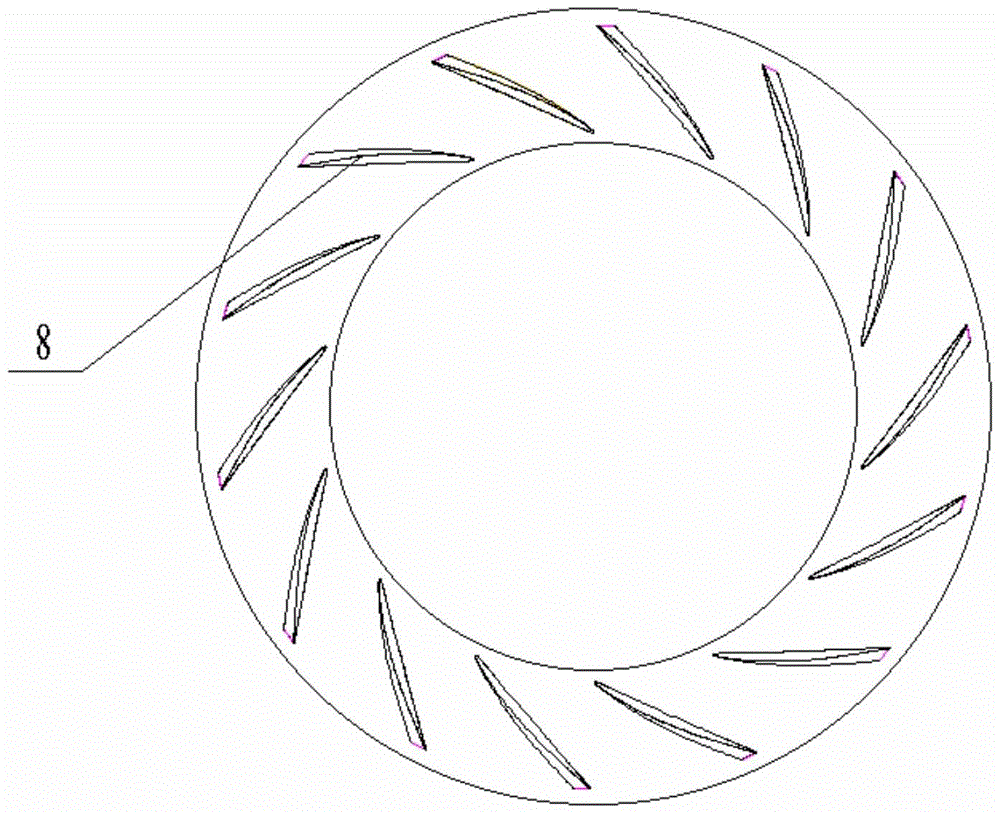

[0040] like Figure 1a and 2 As shown, a model stage of a centrifugal compressor includes an impeller 1 , a vaned diffuser 2 , a bend 3 and a reflux device 4 . The vane diffuser 2 is arranged at the outlet of the impeller 1; the diffuser vane 8 of the vane diffuser 2 is a curved vane, that is, the side of the diffuser vane 8 that is close to the diffuser wheel cover is bent to form a steady outlet. flow sheet; the trailing edge line of the outlet stabilizing sheet and the axial angle of the vane diffuser 2 are 3°, so that the outlet angle of the diffuser blade 8 is enlarged by 3° compared with the original blade; the outlet stabilizing sheet can make The originally unstable air flow on the wheel cover side of the vane diffuser 2 becomes more uniform, reducing the flow loss of gas inside the vane diffuser 2 and improving the overall operating efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com