Pull-push type rope locking device

A rope lock and splint technology, applied in the direction of transmission elements or pulley ropes or cables, textile cables, belts/chains/gears, etc. problems, to achieve the effect of small damage, small change in the included angle, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

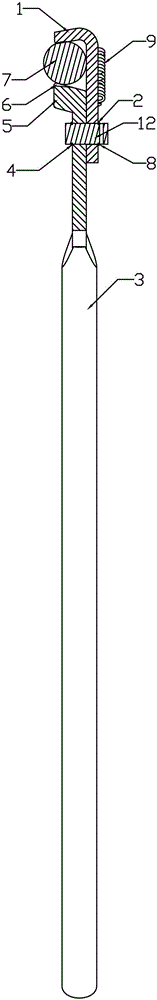

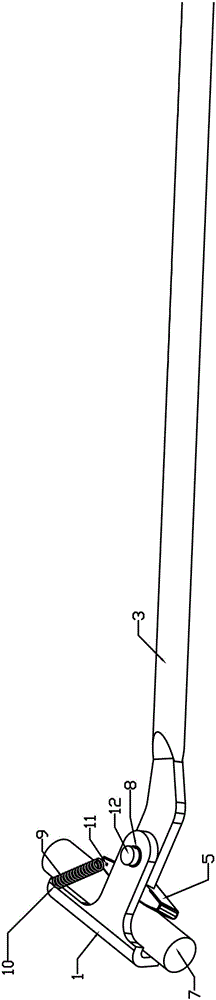

[0036] A pull-push type rope lock, including: a splint 1 and a handle 3. The characteristic is that: the splint 1 and the chuck 5 on the handle 3 form a leverage force through the connecting shaft 12, which can be between the splint 1 and the chuck 5 Lock and clamp the wire rope 7 and the like by applying a pulling force to the handle 3, or release the pulling force on the handle 3 or apply force in the opposite direction, and easily remove the push-pull rope lock from the wire rope . Before using, the return spring 9 keeps a state between the splint 1 and the handle chuck 5 all the time.

[0037] There are anti-slip protrusions on the splint 1 and the chuck 5, and a splint shaft hole 2 and a handle shaft hole 4 are respectively designed on the splint 1 and the handle 3, and the splint 1 can be C-shaped or L-shaped.

[0038] Clamp plate 1 and handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com