Multi-functional natural gas and hydrogen mixing gas station and filling method

A technology of natural gas and gas filling stations, which is applied in the field of gas filling, and can solve problems such as poor energy efficiency, uneven density, and retention, and achieve the effects of avoiding gas mixture stratification, avoiding energy waste, and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

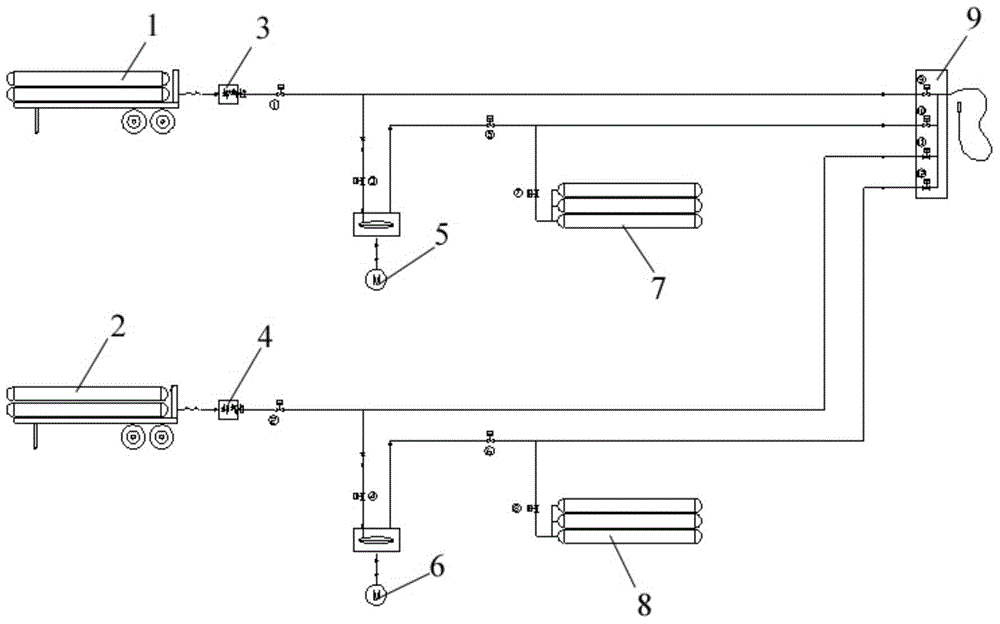

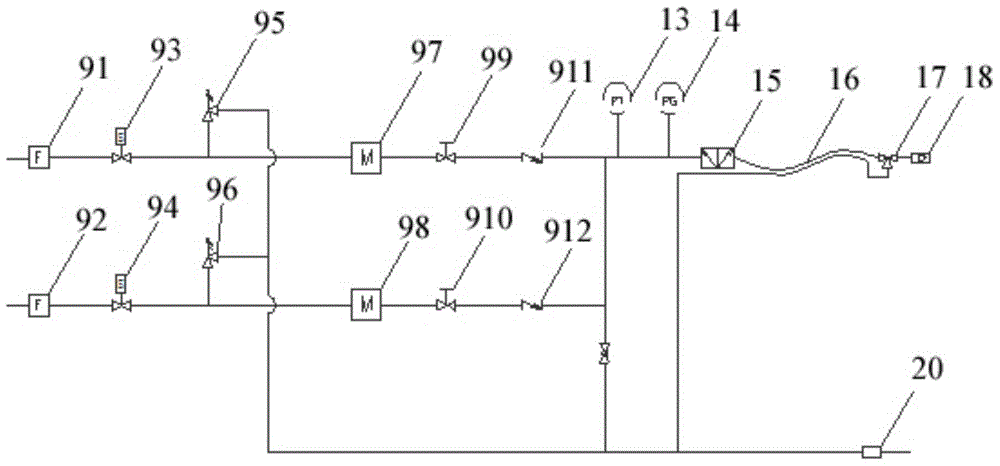

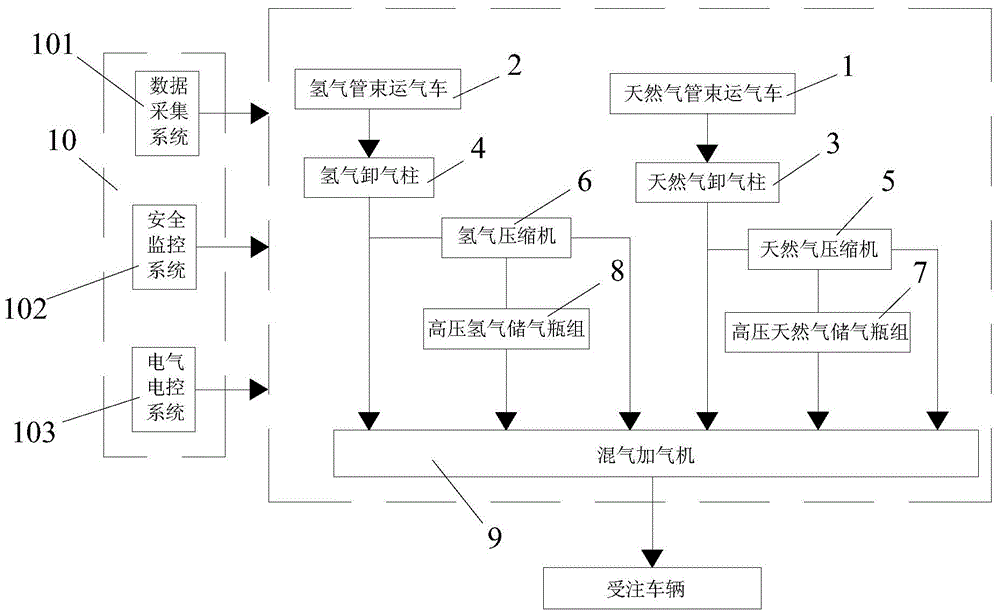

[0031] The natural gas and hydrogen high-pressure mixed gas filling station system as shown in the figure includes: natural gas tube bundle gas carrier 1, hydrogen tube bundle gas carrier 2, natural gas unloading column 3, hydrogen unloading column 4, natural gas compressor 5, hydrogen compressor 6 , High-pressure natural gas cylinder group 7, high-pressure hydrogen gas cylinder group 8, gas mixing dispenser 9 and SCADA system 10.

[0032] The natural gas tube bundle tanker 1 is connected to the gas mixer 9 through pipelines. The downstream pipeline of the natural gas bundle tanker 1 is provided with a natural gas unloading column 3, and a group of high-pressure natural gas storage cylinders 7 are connected to the gas mixer through pipelines. Engine 9, the natural gas tube bundle gas transport vehicle 1 is connected to the high-pressure natural gas storage cylinder group 7 through the pipeline after the corresponding natural gas unloading column 3, and the natural gas compressor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com