cng transport ship piping system

A pipeline system and transport ship technology, which is applied in the field of CNG transport ships and compressed gas marine transportation systems, can solve the problems of increasing the difficulty of pipeline maintenance and overhaul, increasing the complexity of pipeline settings, and limiting the number of pressure bottles, etc., to achieve Facilitate maintenance and overhaul, flexible space for pipeline layout, and eliminate the effect of relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

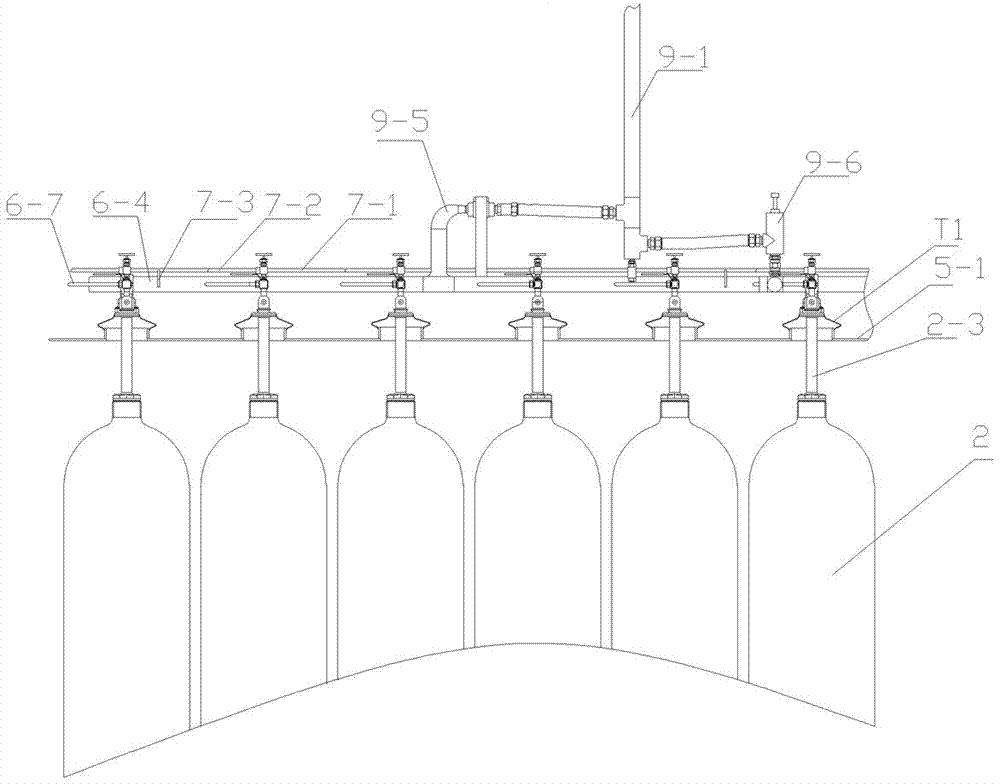

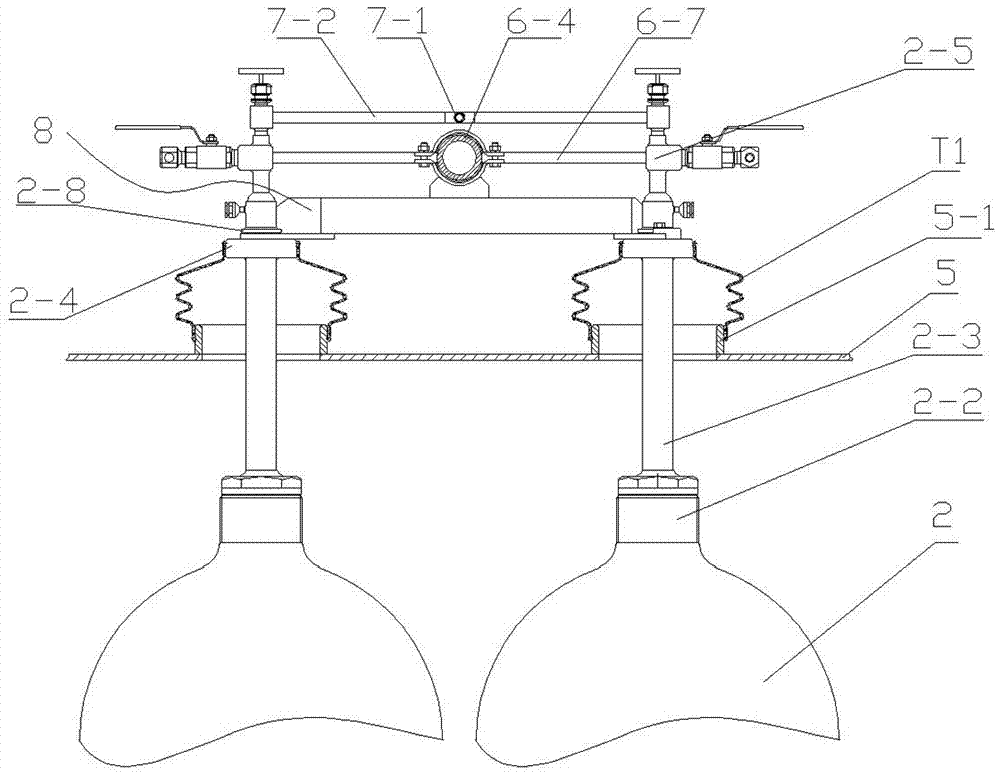

[0024] see figure 1 , a pipeline system for a CNG transport ship, including a loading and unloading pipeline subsystem, a safety discharge pipeline subsystem, a maintenance pipeline subsystem, and a management circuit supporting each subsystem. The circuit, the upper end plug assembly of the gas cylinder, the controlled pneumatic valve and each gas cylinder are connected on and off; The system and the mechanism with the attached manual control part and the random detection display part are arranged on both sides of the touring channel of the hatch cover 5-1.

[0025] The maintenance pipeline subsystem includes a sewage pipeline system and nitrogen purging, replacement and sealing inspection subsystems.

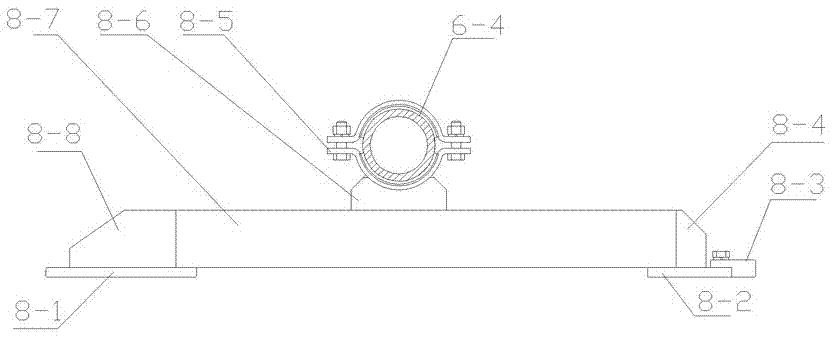

[0026] The loading and unloading gas pipeline sub-system is erected above the hatch cover 5-1 by means of the random self-adaptive bracket 8 and the limit post limited on the upper end plug assembly; the sewage pipeline sub-system is erected on the The top of the loading and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com