Photoresist collection cup structure to prevent wafer front and back side contamination

A technology of photoresist and collection cup, applied in the direction of photoplate making process coating equipment, etc., can solve the problems of polluting wafers, waste liquid polluting wafers, low yield, etc., to prevent pollution, improve yield, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

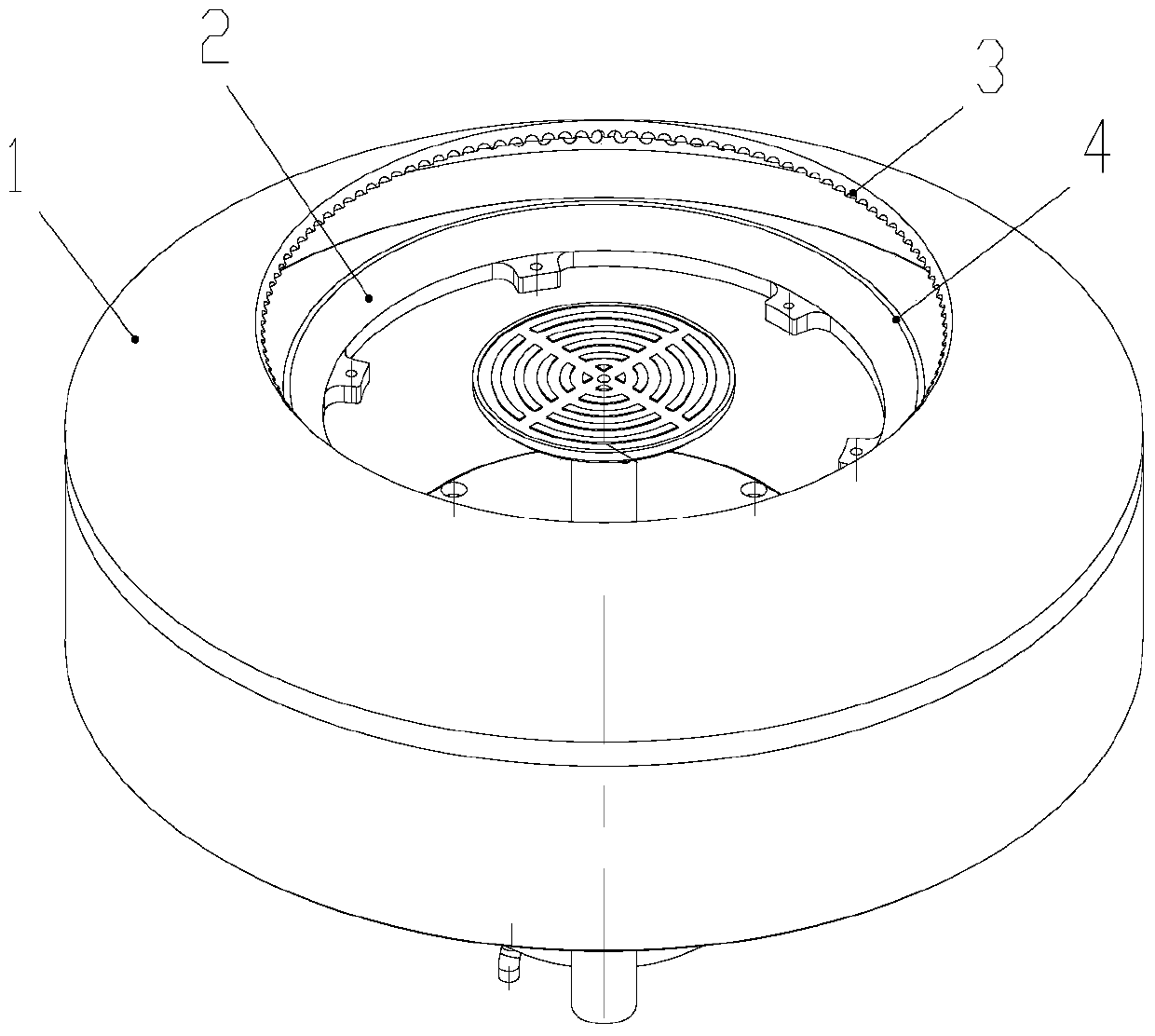

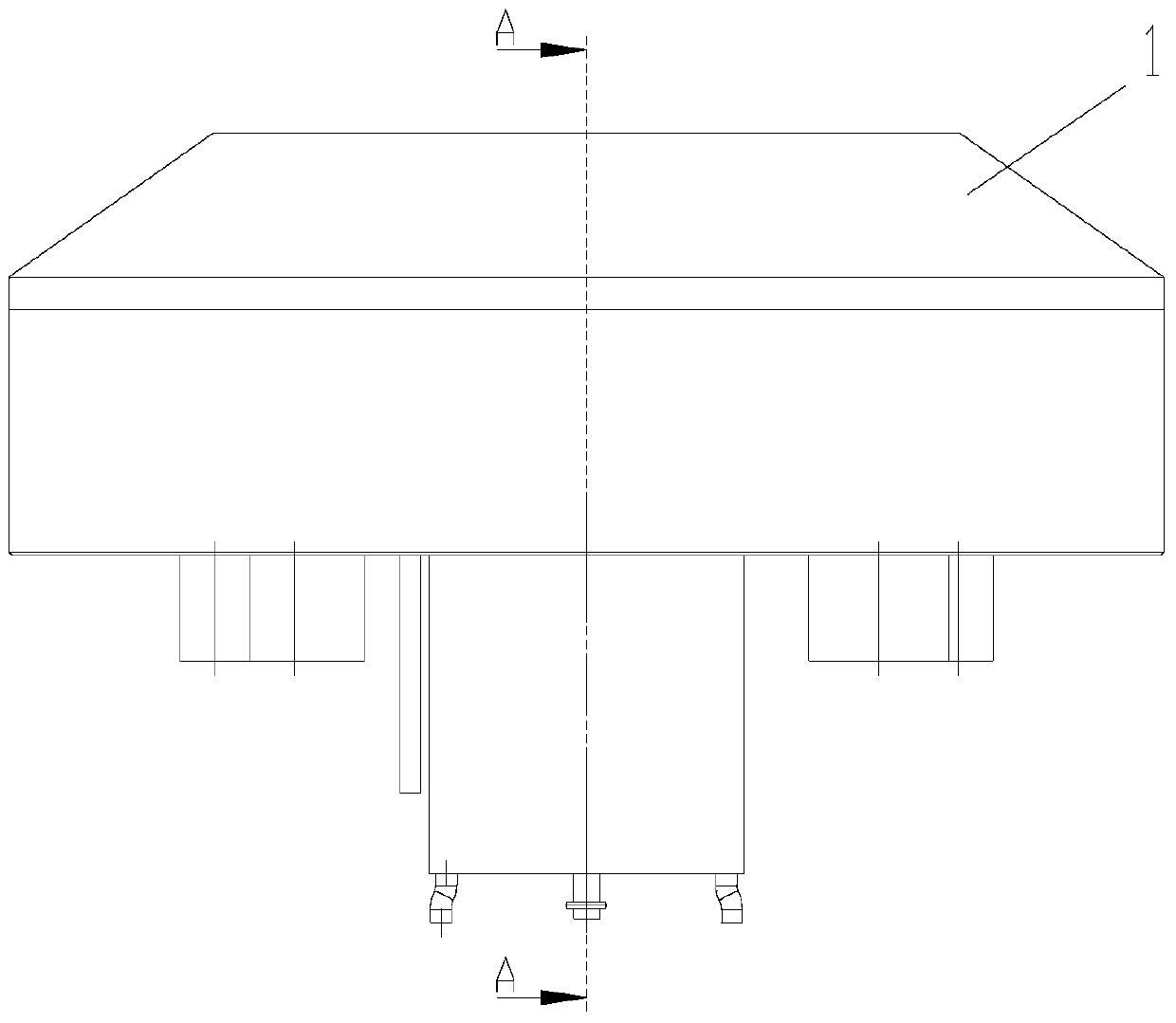

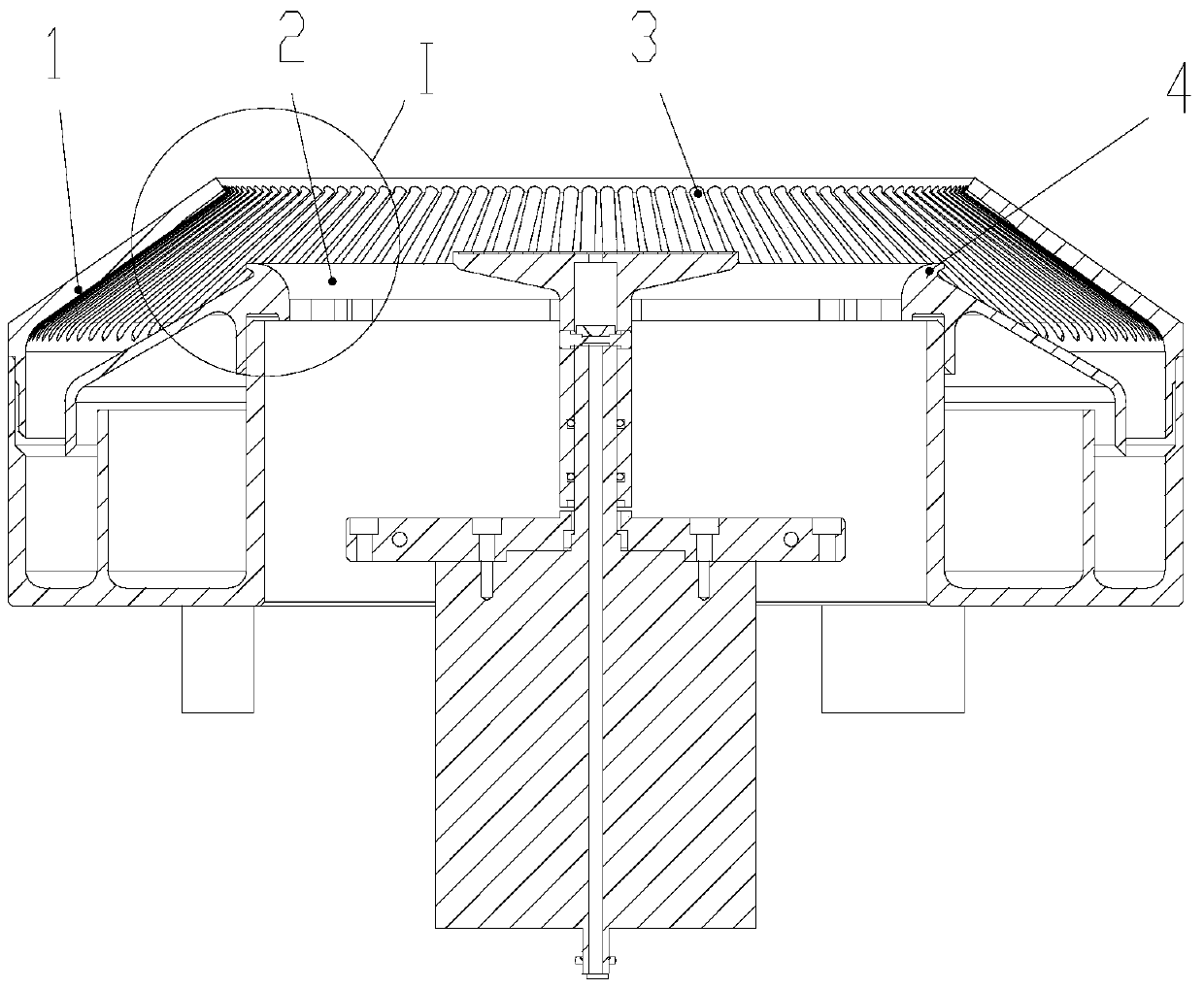

[0018] Such as Figure 1-3 As shown, the present invention includes an upper cup 1 and a lower cup 2. The inner wall of the upper cup 1 is provided with a diversion groove structure 3 for guiding the waste liquid to flow downwards, and the upper edge of the lower cup 2 is provided along the circumference to prevent waste Liquid backflow prevention structure 4.

[0019] Such as Figure 4 As shown, the diversion groove structure 3 is a plurality of side-by-side grooves that are evenly distributed on the inner wall of the upper cup 1 and arranged along the inner wall from top to bottom. The backflow preventing structure 4 is an annular retaining ring provided on the upper edge of the lower cup 2 to form a backflow preventing structure.

[0020] The working principle of the present invention is:

[0021] During the wafer production process, the excess waste liquid (pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com