Plasma reactor and method for removing particulate contamination from plasma reaction chamber

A plasma and reaction chamber technology, used in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., to solve problems such as particle pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

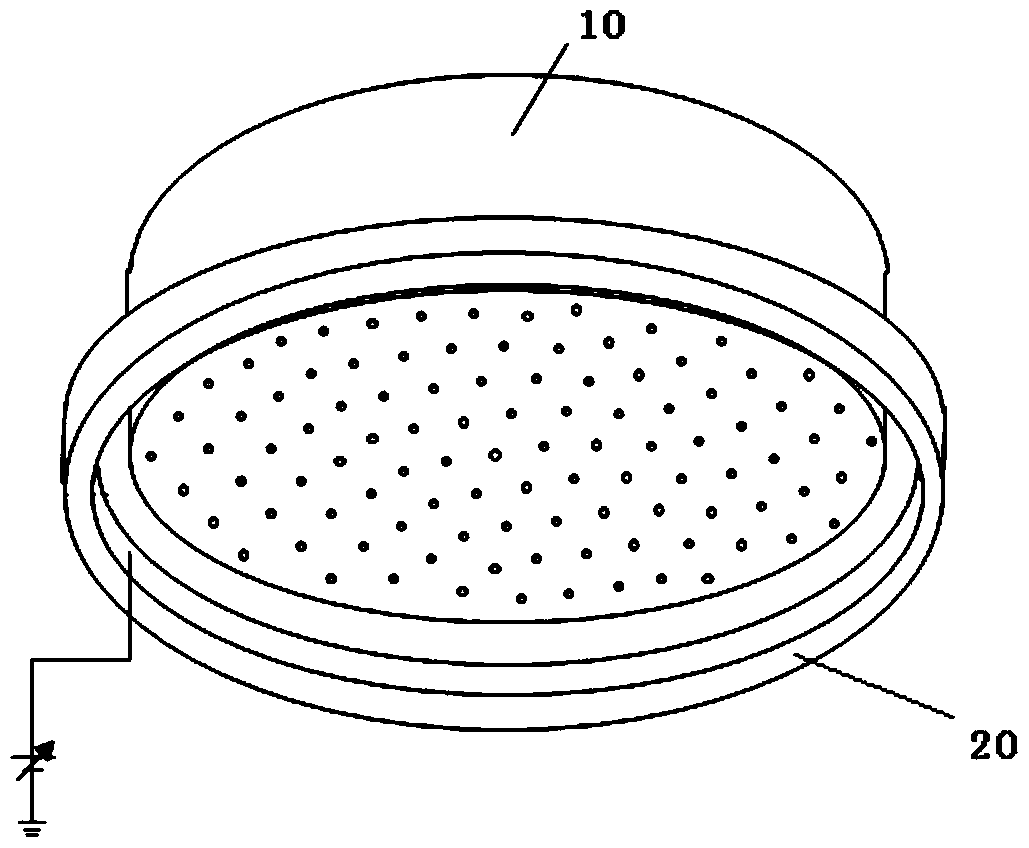

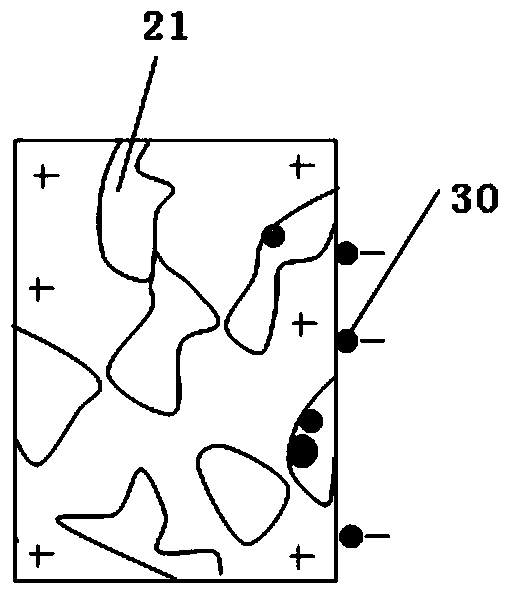

[0032] A typical plasma reactor in the prior art usually includes a casing, in which there is a reaction chamber, and the top and bottom of the reaction chamber are respectively provided with an upper pole plate and a lower pole plate correspondingly. The upper pole plate and the lower pole plate are separated by an insulating part, and the top of the lower pole plate can support the workpiece to be processed. The above-mentioned processing workpieces shall include wafers and other processing workpieces with the same processing principle.

[0033] When the plasma reactor is working, a vacuum device such as a dry pump is used to create and maintain a near-vacuum state in the reaction chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com