A preparation method of porous polymer microspheres with heavy metal chelating function

A technology of polymer microspheres and heavy metals, which is applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Efficiency and other issues, to achieve the effect of easy removal, large specific surface area, and efficient adsorption and removal of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

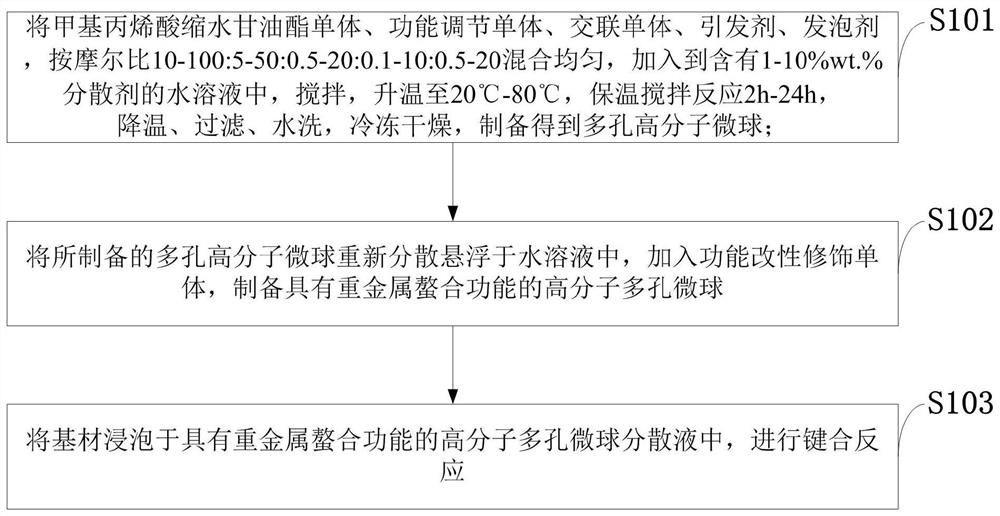

[0024] Such as figure 1 As shown, the preparation method of porous polymer microspheres with heavy metal chelating function provided by the embodiments of the present invention includes the following steps:

[0025] S101: Glycidyl methacrylate monomer, function adjustment monomer, crosslinking monomer, initiator, foaming agent, by molar ratio 10-100:5-50:0.5-20:0.1-10:0.5- 20, mix evenly, add to the aqueous solution containing 1-10%wt.% dispersant, stir, heat up to 20°C-80°C, keep warm and stir for 2h-24h, cool down, filter, wash with water, freeze-dry, and prepare the porous high molecular microspheres;

[0026] S102: redispersing and suspending the prepared porous polymer microspheres in an aqueous solution, adding functional modification monomers to prepare polymer porous microspheres with a heavy metal chelating function;

[0027] S103: Soak the base material in the polymer porous microsphere dispersion liquid with heavy metal chelating function, and carry out the bondin...

Embodiment 1

[0039] The preparation and application of the porous polymer microspheres with heavy metal chelating function provided by the embodiment of the present invention comprises the following steps:

[0040] (1) In 100ml of water, add 5ml of Tween 80, keep the temperature at 80°C, add 20g of glycidyl methacrylate, 5g of methyl acrylate, 0.5g of pentaerythritol triacrylate, 4g of benzoyl peroxide, and 10ml of petroleum ether under stirring , react at 80°C for 6 hours, filter, wash with water, and freeze-dry to obtain porous polymer microspheres;

[0041] (2) Place the porous polymer microspheres prepared in step (1) in 20wt.% ethylenediamine solution, soak for 24 hours with shaking at 20°C, filter, wash with water, and freeze-dry to obtain the porous polymer with heavy metal chelating function Microspheres.

[0042](3) the brass mesh is placed in the water-ethanol mixed solution (water / ethanol is 1:1) of the porous polymer microspheres with heavy metal chelating function prepared in...

Embodiment 2

[0044] The preparation and application of the porous polymer microspheres with heavy metal chelating function provided by the embodiment of the present invention comprises the following steps:

[0045] (1) In 100ml of water, add 8ml of sorbitan monostearate, at a constant temperature of 75°C, add 30g of glycidyl methacrylate, 5g of methacrylic acid, 1g of polyethylene glycol diacrylate, 2g of supernatant Benzoyl oxide and 20ml of n-heptane were reacted at 75°C for 10 hours, filtered, washed with water, and freeze-dried to obtain porous polymer microspheres;

[0046] (2) Place the porous polymer microspheres prepared in step (1) in a 5wt.% thioglycolic acid solution, shake and soak at 30°C for 12 hours, filter, wash with water, and freeze-dry to obtain a porous polymer with heavy metal chelating function Microspheres.

[0047] (3) Sisal fibers are placed in the water-ethanol mixed solution (water / ethanol is 1:1) of the porous polymer microspheres with heavy metal chelating fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com