Heavy metal chelating agent as well as preparation method and application thereof

A heavy metal chelating agent and reaction technology, applied in the direction of condensation/addition reaction to prepare amino compounds, organic chemistry, improvement of process efficiency, etc., can solve the problems of small chelation area, few chelation points, and small chelation volume, and achieve Effect of Chelating Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

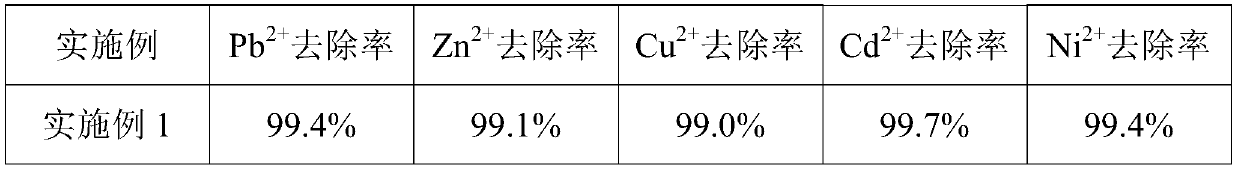

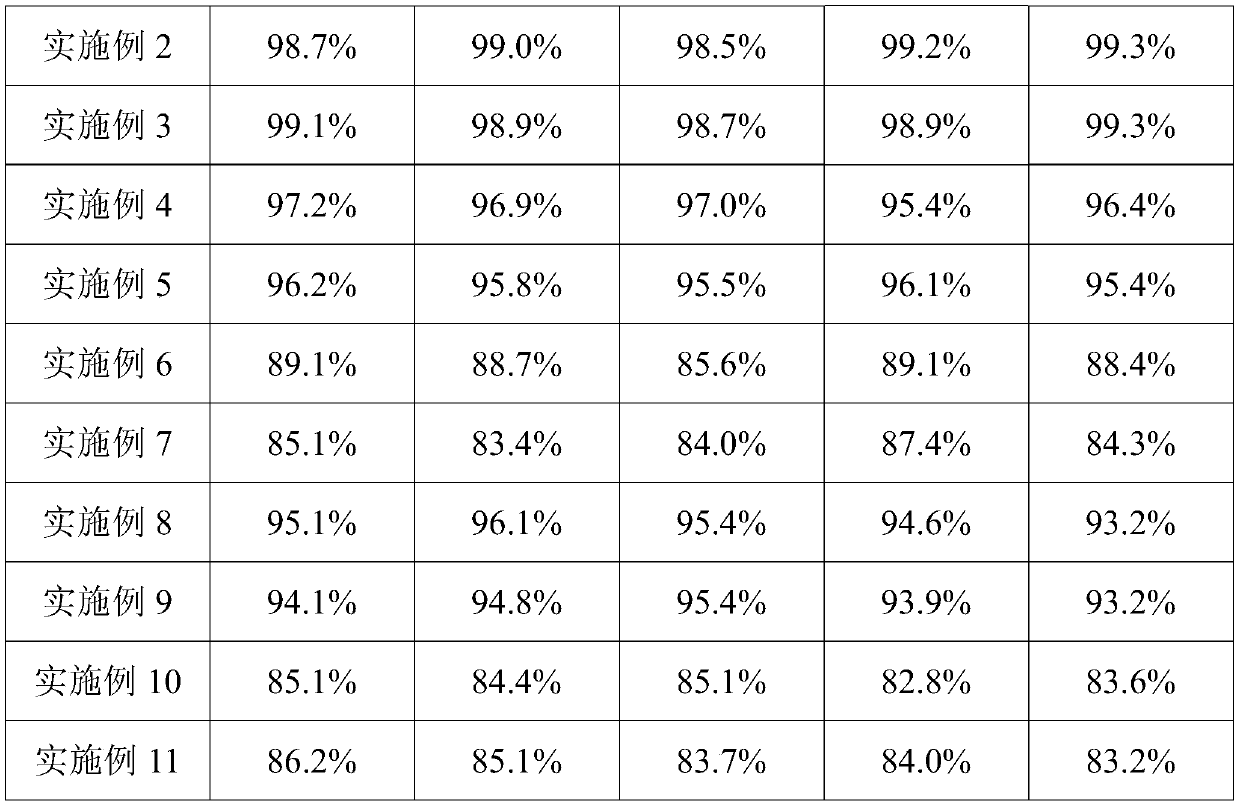

Examples

Embodiment 1

[0074] The present embodiment provides a kind of heavy metal chelating agent, and its preparation method comprises the steps:

[0075] (1) Dissolve diethylenetriamine and solid sodium hydroxide in deionized water at 0°C, slowly add di-tert-butyl dicarbonate dropwise through the dropping funnel under vigorous stirring, and return to 25 ℃ for 3 hours to obtain unilaterally protected diethylenetriamine;

[0076] (2) Cool the above reaction system to 0°C with an ice-water bath again, and then slowly add 1,2-dichloroethane dropwise to it through the dropping funnel under vigorous stirring, and control the dropping rate for about 6 seconds per drop. After the dropping is completed, Return to 25°C and react for 2 hours to obtain crosslinked diethylenetriamine; the molar ratio of 1,2-dichloroethane to unilaterally protected diethylenetriamine is 1:2;

[0077] (3) Slowly add 6N HCl solution dropwise to the above reaction system until the pH value of the system reaches 4, and react at ...

Embodiment 2

[0080] The present embodiment provides a kind of heavy metal chelating agent, and its preparation method comprises the steps:

[0081] (1) Dissolve triethylenetetramine and solid potassium hydroxide in deionized water at 0°C, slowly add di-tert-butyl dicarbonate dropwise through the dropping funnel under vigorous stirring, and return to 20°C after the dropwise addition is completed. ℃ for 3 hours to obtain triethylenetetramine with unilateral protection;

[0082] (2) Cool the above reaction system to 0°C with an ice-water bath again, then slowly add 1,3-dichloropropane dropwise to it through the dropping funnel under vigorous stirring, and control the dropping rate for about 5 seconds per drop, and resume after the dropping is completed React at 30°C for 1 hour to obtain cross-linked triethylenetetramine; the molar ratio of the 1,3-dichloropropane to the unilaterally protected triethylenetetramine is 1:2;

[0083] (3) Slowly add 6N acetic acid solution dropwise to the above r...

Embodiment 3

[0086] The present embodiment provides a kind of heavy metal chelating agent, and its preparation method comprises the steps:

[0087] (1) Dissolve diethylenetriamine and solid sodium hydroxide in deionized water at 0°C, slowly add di-tert-butyl dicarbonate dropwise through the dropping funnel under vigorous stirring, and return to 30°C after the dropwise addition is completed. ℃ for 2 hours to obtain unilaterally protected diethylenetriamine;

[0088] (2) Cool the above reaction system to 0°C with an ice-water bath again, then slowly add 1,4-dichlorobutane dropwise through the dropping funnel under vigorous stirring, and control the dropping rate for about 5 seconds per drop. Return to 20°C and react for 3 hours to obtain crosslinked diethylenetriamine; the molar ratio of 1,4-dichlorobutane to unilaterally protected diethylenetriamine is 1:2;

[0089] (3) Slowly add 6N HCl solution dropwise to the above reaction system until the pH value of the system reaches 3.5, and react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com