Skull replacing apparatus of 3D print and manufacturing method thereof

A 3D printing and skull technology, applied in bone implants, medical science, prostheses, etc., can solve problems such as dysfunction, insufficient protection of brain tissue, and inability to meet the refinement requirements of patients' defect parts, and achieve strong Applicability, taking into account compatibility and biological activity, and beneficial to the effect of attachment growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

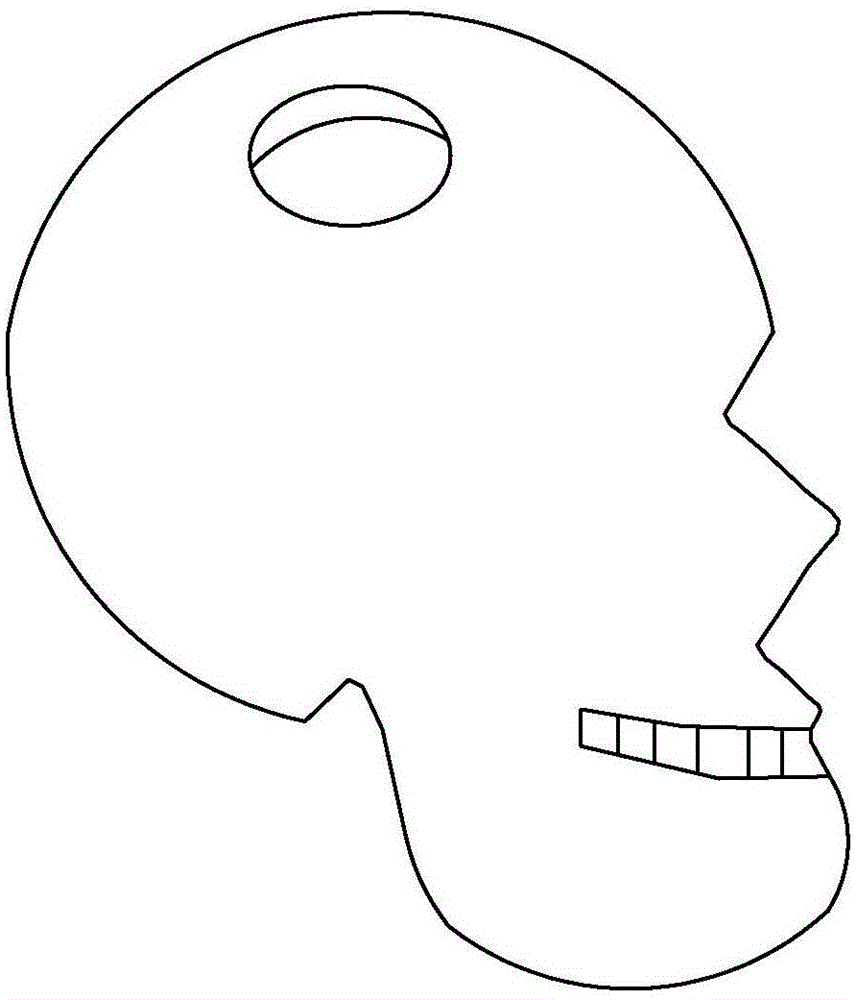

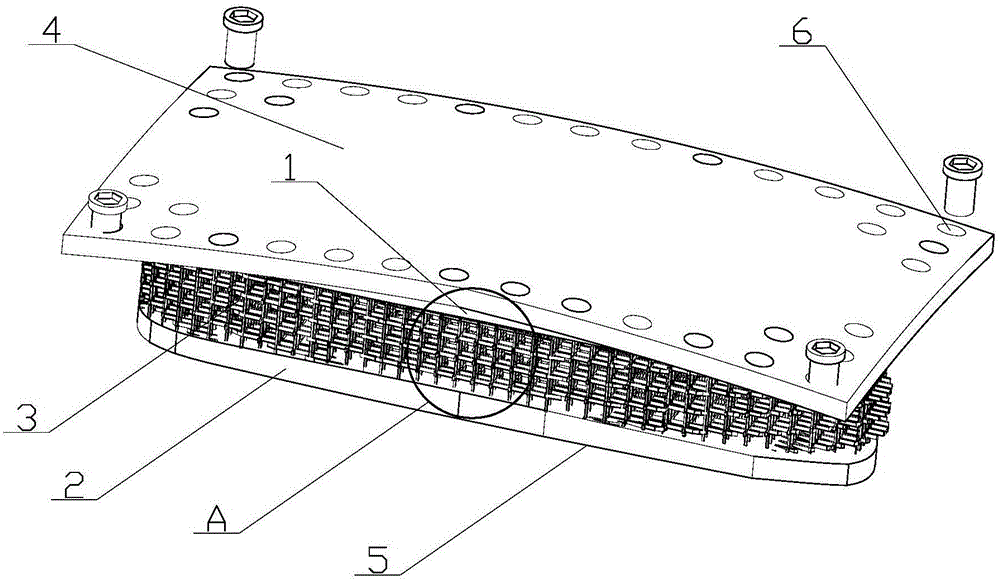

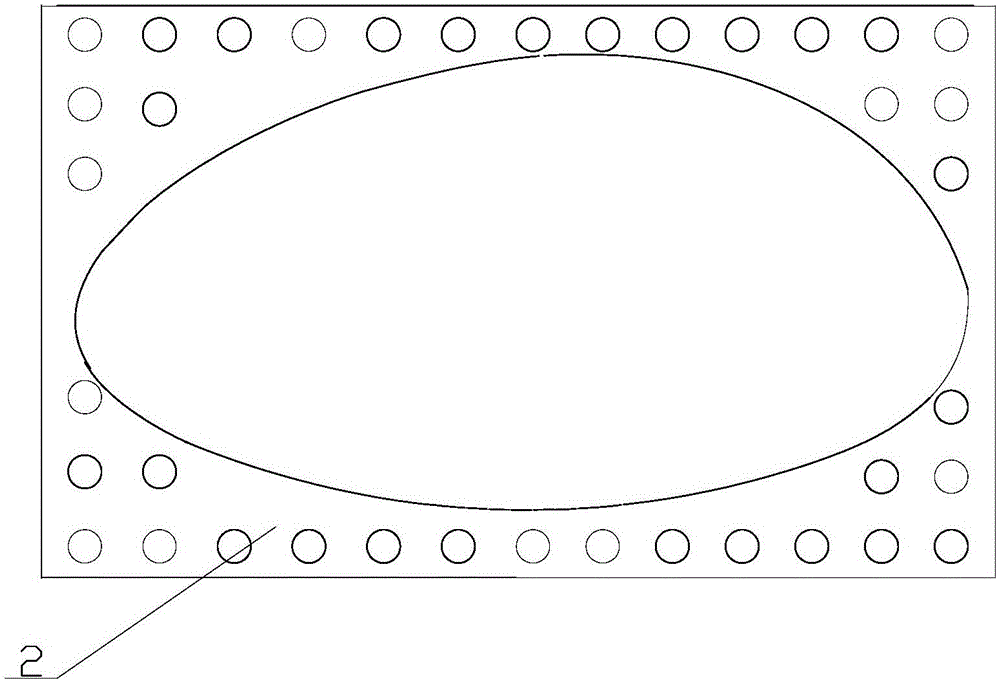

[0022] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a 3D printed skull replacement device in this embodiment, including a fixed piece 4, a dense layer 1, a dense layer 2 and a transition layer 3, the fixed piece 4 and the dense layer 1 are formed from the top The bottom is located above the transition layer 3 in sequence, the dense layer 2 is located below the transition layer 3 and the dense layer 1 and the dense layer 2 are connected through the transition layer 3, the dense layer 1, the transition layer 3 and the dense layer Layer 2 has the same shape as the defective skull, and transition layer 3 is a microscopic truss structure.

[0023] The connection between the present embodiment and the skull during use is installed on the outer periphery of the fixing piece 4 through a plurality of bolts, so as to realize the connection between the skull and the present embodiment.

specific Embodiment approach 2

[0024] Specific implementation mode two: combination Figure 2 to Figure 4 This embodiment is described, and this embodiment also includes an active coating 5 deposited on the outer surfaces of the dense layer 1 , the dense layer 2 , and the transition layer 3 . Such setting not only preserves the mechanical properties of the metal matrix, but also takes into account the compatibility and biological activity of the coating. The other composition and connection relationship are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 2 The present embodiment will be described. The active coating layer 5 of the present embodiment is a hydroxyapatite coating layer. Such setting is conducive to the attachment and growth of tissue cells and promotes osseointegration. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com