High-dissolubility children's calcium carbonate D3 granule and preparation method thereof

A technology of calcium carbonate and dissolution rate, which is applied in pharmaceutical formulations, active ingredients of aluminum/calcium/magnesium, medical preparations of non-active ingredients, etc., can solve problems such as unsatisfactory dissolution rate of calcium carbonate particles, and is suitable for large-scale production , less ingredients, the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

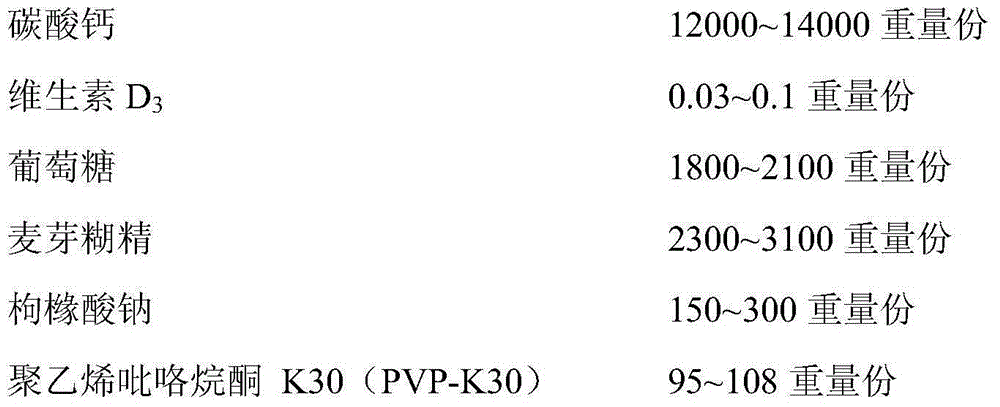

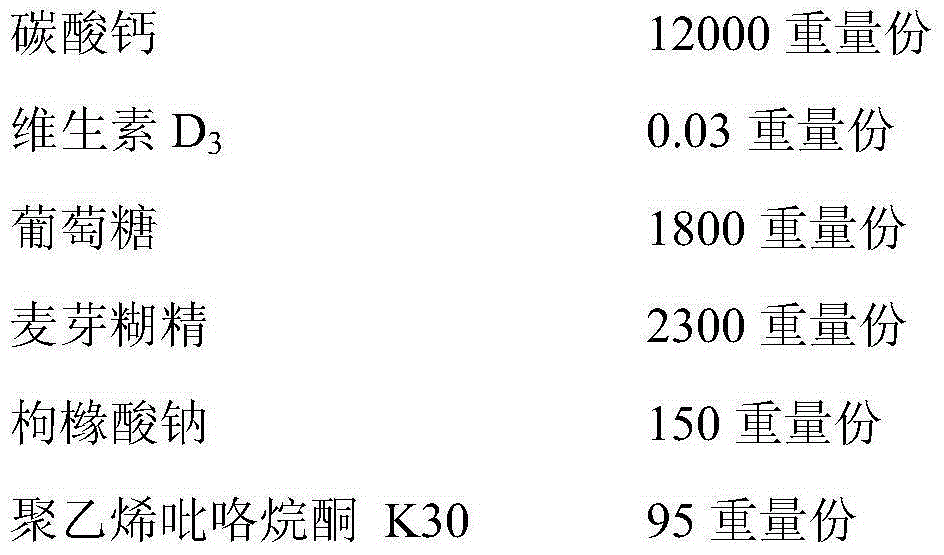

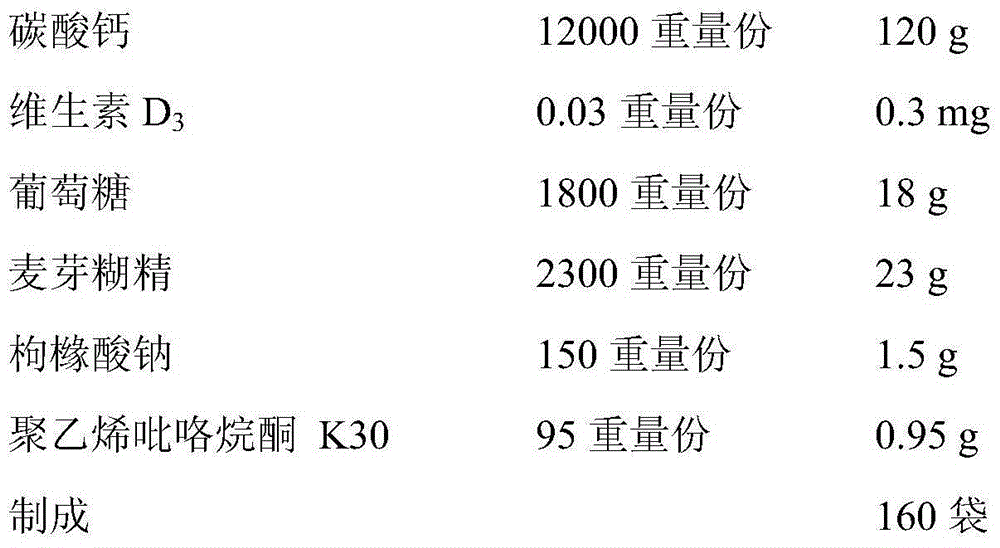

[0020] Prescription 1

[0021]

[0022] Preparation

[0023] (1) After crushing 120g of calcium carbonate, pass through a 160-mesh sieve, 18g of glucose, 23g of maltodextrin and 1.5g of sodium citrate, pass through a 80-mesh sieve respectively, and then place the fine powder in a high-efficiency wet mixing granulator , mixed for 10min.

[0024] (2) Dissolve 0.95g of PVP-K30 in absolute ethanol to prepare a 10% PVP-K30 ethanol solution.

[0025] (3) Weigh 0.3mg vitamin D 3 , dissolved in PVP-K30 ethanol solution with a mass concentration of 10%, stirred to dissolve it completely, and then vitamin D 3 Add the solution into a high-efficiency wet mixing granulator, and rinse the container with an appropriate amount of absolute ethanol for 3 times. The sodium citrate mixture was mixed for 15 minutes, then an appropriate amount of 30% ethanol aqueous solution was added, cut and mixed for 4 minutes, and then the soft material was transferred to a swing granulator, and passed t...

Embodiment 2

[0029] Prescription 2

[0030]

[0031] Preparation

[0032] (1) After crushing 130g of calcium carbonate, pass through a 160-mesh sieve, 19g of glucose, 28g of maltodextrin and 2g of sodium citrate and pass through a 80-mesh sieve respectively, and then place the fine powder in a high-efficiency wet mixing granulator, Mix for 10 min.

[0033] (2) Dissolve 1 g of PVP-K30 in absolute ethanol to prepare a 10% PVP-K30 ethanol solution.

[0034] (3) Weigh 0.5mg vitamin D 3 , dissolved in PVP-K30 ethanol solution with a mass concentration of 10%, stirred to dissolve it completely, and then vitamin D 3 Add the solution into a high-efficiency wet mixing granulator, and rinse the container with an appropriate amount of absolute ethanol for 3 times. The sodium citrate mixture was mixed for 15 minutes, then an appropriate amount of 30% ethanol aqueous solution was added, cut and mixed for 4 minutes, and then the soft material was transferred to a swing granulator, and passed thro...

Embodiment 3

[0038] Prescription 3

[0039]

[0040] Preparation

[0041] (1) Grind 138g of calcium carbonate and pass through a 160-mesh sieve, 20g of glucose, 29g of maltodextrin and 2.5g of sodium citrate and pass through a 80-mesh sieve respectively, and then place the fine powder in a high-efficiency wet mixing granulator , mixed for 10min.

[0042] (2) Dissolve 1.05g of PVP-K30 in absolute ethanol to prepare a 10% PVP-K30 ethanol solution.

[0043] (3) Weigh 0.8mg vitamin D 3 , dissolved in PVP-K30 ethanol solution with a mass concentration of 10%, stirred to dissolve it completely, and then vitamin D 3 Add the solution into a high-efficiency wet mixing granulator, and rinse the container with an appropriate amount of absolute ethanol for 3 times. The sodium citrate mixture was mixed for 15 minutes, then an appropriate amount of 30% ethanol aqueous solution was added, cut and mixed for 4 minutes, and then the soft material was transferred to a swing granulator, and passed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com